A zinc film remover

A material and dust-proof technology, applied in the direction of chemical instruments and methods, layered products, lamination auxiliary operations, etc., can solve the problems that the film is difficult to completely tear off, the film is difficult to reuse, and the film is difficult to completely remove, so as to achieve maintenance Convenience, low cost, favorable discharge effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

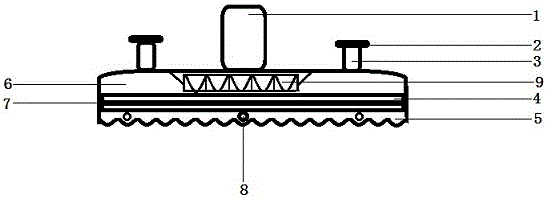

[0016] Such as figure 1 A zinc film remover shown is composed of a handle 1, a housing 6, a water bag 5, a water injection port 3, and a winding rod 4. The handle 1 is located on the upper part of the housing 6, and the water injection port 3 is located at The upper part of the housing 6, the water bag 5 is connected to the lower part of the housing 6, and the winding rod 4 is located at the lower part of the housing 6.

[0017] A tape groove 7 is arranged in the middle of the winding rod 4 .

[0018] The material of the winding rod 4 is rubber.

[0019] Dustproof device 2 is arranged on described water injection port 3.

[0020] The dustproof device 2 is made of rubber.

[0021] The water bag 5 is provided with a water outlet 8, the water outlet 8 is located at the side of the water bag 5, and the water outlet 8 is provided with a plug.

[0022] A heater 9 may be provided in the housing 6 .

[0023] The winding rod 4 is movably connected with the casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com