Nail automatic packaging machine

An automatic packaging machine and iron nail technology, which is applied in the directions of packaging, transportation and packaging, and the type of packaging items, can solve the problems of complex maintenance and repair, complex structure, poor nail row effect, etc., and achieves good nail row effect and simple structure. , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

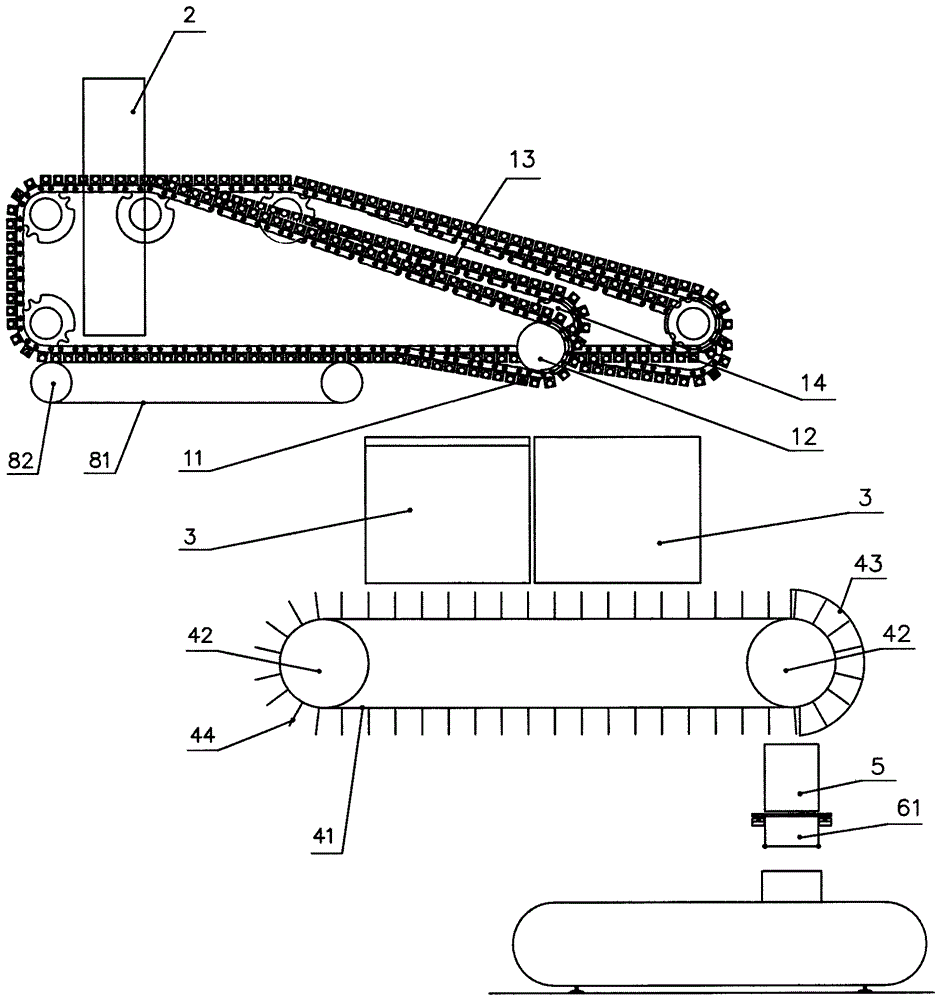

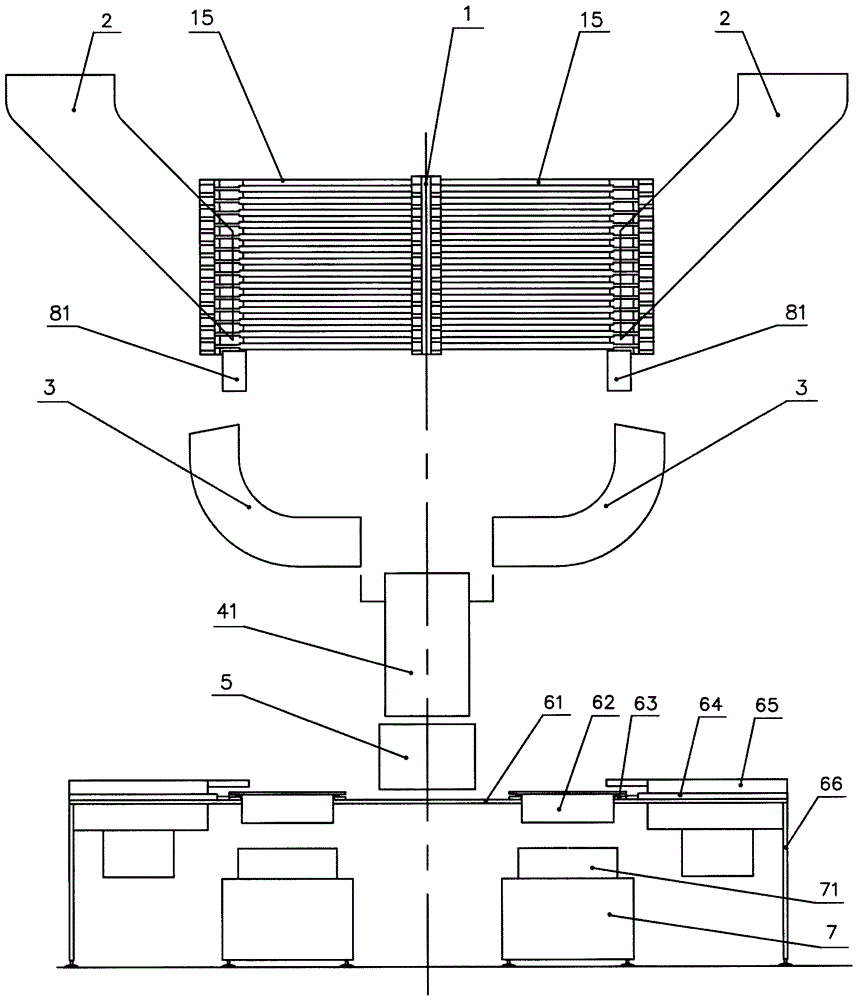

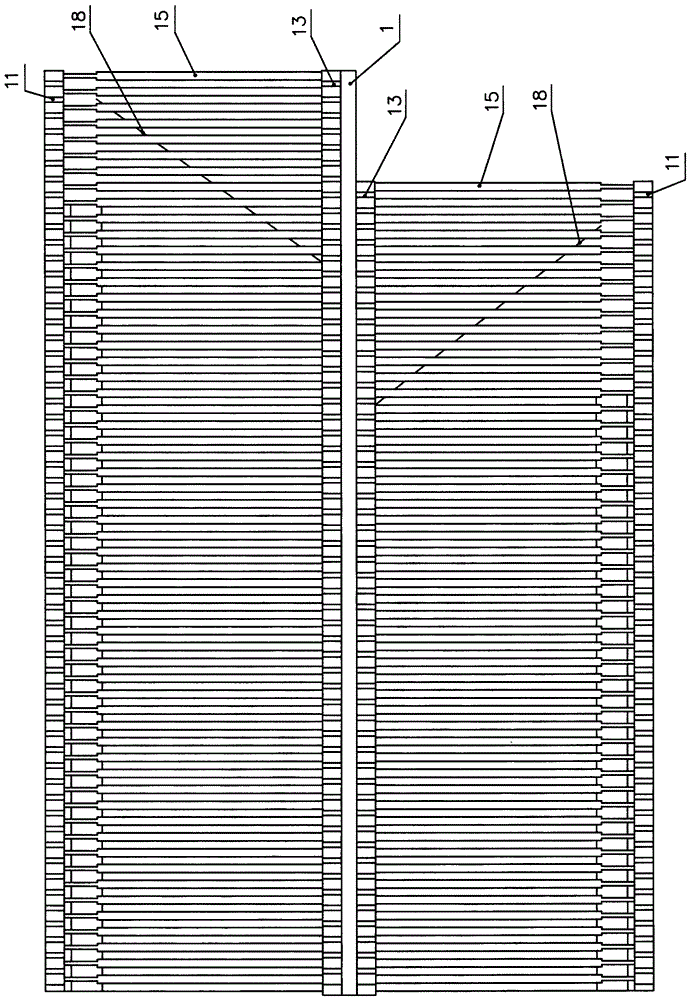

[0015] The nail automatic packaging machine includes a sorting device, a conveying device and a weighing and packing device. see figure 1 and figure 2 , The sorting device includes a support frame 1, a feed hopper 2, a vibrator, a turning bucket 3 and two sets of chain net nail removal mechanisms arranged on the support frame 1. The vibrator is used to vibrate the supporting frame 1, thereby vibrating the two groups of chain net nail arranging mechanisms. The vibrator can be a vibrating motor or other vibrating mechanism. Each group of chain net nail removal mechanisms includes a power source, an outer chain 11, an outer sprocket 12 engaged with the outer chain, an inner chain 13, an inner sprocket 14 engaged with the inner chain, and a plurality of cross bars 15 arranged side by side. The outer chain 11 and the inner chain 13 are arranged in parallel and move synchronously, and the power source is used to drive the outer sprocket 12 and the inner sprocket 14, thereby driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com