Mobile Inclined Refining Unit

A kind of oil refining equipment, inclined technology, applied in the field of oil refining equipment and waste plastic refining equipment, can solve the problems of increasing the flow resistance of plastic melt, easy deposition of solid matter, and limiting processing capacity, etc., to avoid slag accumulation in the kettle, Simple and controllable operation, low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

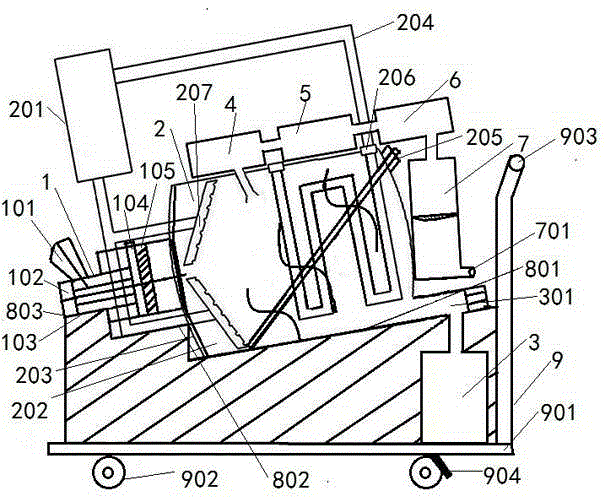

[0020] Embodiment one: if figure 1 As shown, the movable inclined oil refinery includes a feed device 1, a reactor 2, an oil residue treatment device 3, a catalytic device 4, a cooling device 5, an oil-water separation device 6, and a filter and impurity removal device 7, as well as a base 8 , the base 8 has an inclined plane 801, the reactor 2 is placed on the base 8 obliquely, and the base 8 has a pusher 9; the pusher 9 makes the base 8 movable; one end of the reactor 2 is connected with the feeding device 1, and the reactor The other end of 2 is connected with one end of catalytic device 4, and the other end of catalytic device 4 is connected with one end of cooling device 5; the other end of cooling device 5 is connected with one end of oil-water separation device 6, and the other end of oil-water separation device 6 One end is connected with one end of the filter impurity removal device 7; the filter impurity removal device 7 is provided with an oil outlet 701; the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com