Aluminum Alloy Plate For Hood Inner Panel Of Automobile And Manufacturing Method Thereof

A technology for automobile engines and aluminum alloy plates, which is applied to vehicle components, superstructure sub-assemblies, transportation and packaging, etc., can solve the problems of decreased yield strength, increased reaction force, and inability to meet head injury values. The effect of low external damage value and excellent shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

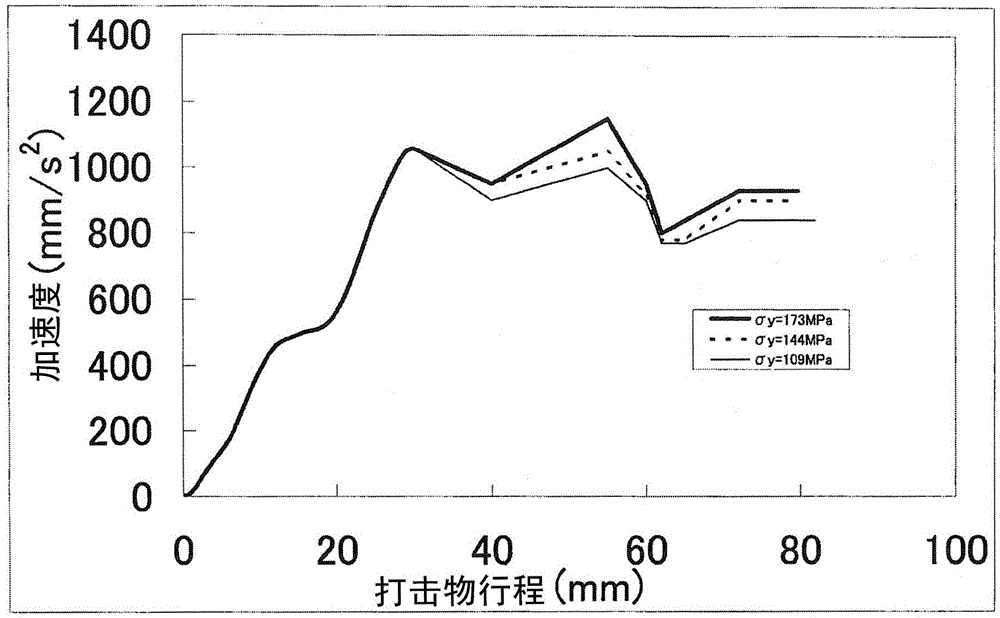

[0123] Embodiments of the present invention are described below. According to the above composition or quenching and tempering treatment after cold rolling, 6000 series aluminum alloy plates with different yield strength conditions specified in the present invention were produced separately, and the mechanical properties and internal properties after being kept at room temperature for 100 days (room temperature aging) were measured and evaluated. The required characteristics of the panel. The properties required for the inner panel refer to the 0.2% yield strength after baking (B H property), the handling property of the panel (only indicated as handling property in Table 2), and the press formability. In addition, the HIC value was obtained from the yield strength value after the baking.

[0124] The yield strength of the above-mentioned plates was produced by changing the heat treatment conditions (tempering conditions) as shown in Table 2 of the 6000-series aluminum alloy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com