An automatic crotch cutting device for textile socks and a control method thereof

A kind of hosiery and automatic technology, applied in textiles, papermaking, knitting, etc., can solve the problems of high labor intensity and inoperability, and achieve the effects of improving production efficiency, alleviating labor pressure, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

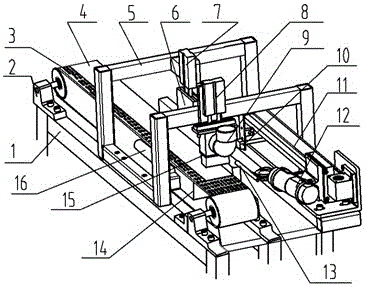

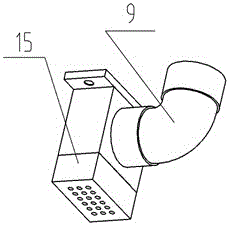

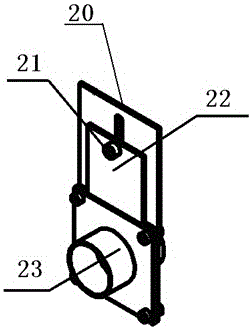

[0055] Such as figure 1 As shown, an automatic crotch-cutting device for weaving pantyhose pants includes an air-permeable conveyor belt 3, a crotch-cutting unit, a negative pressure suction unit and a detection unit for transmitting the pantyhose panties 4; Above the sock pressing cylinder 7, the negative pressure cylinder 8 and the sock cutting knife 12, the piston end of the sock pressing cylinder 7 is connected with the sock head 6, and the piston end of the negative pressure cylinder 8 is connected with the upper negative pressure head 15; 3. A lower negative pressure head 14 is arranged on the lower side in symmetry with the upper negative pressure head 15; , the lower negative pressure pipe 16, the upper negative pressure pipe 9 and the lower negative pressure pipe 16 are connected with the air extractor 19 respectively; The ends are electrically connected with the control circuit of the driving motor 24 of the conveyor belt 3, the sock pressing cylinder 7 and the nega...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com