Nozzle assembly inside warm water body cleaning device

A body cleaner and nozzle technology, which is applied in the field of warm water body cleaners, can solve the problem of irregular service life of the first nozzle port or the second nozzle port, and achieve the effects of reducing replacement costs, prolonging the cleaning cycle and increasing the mixing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

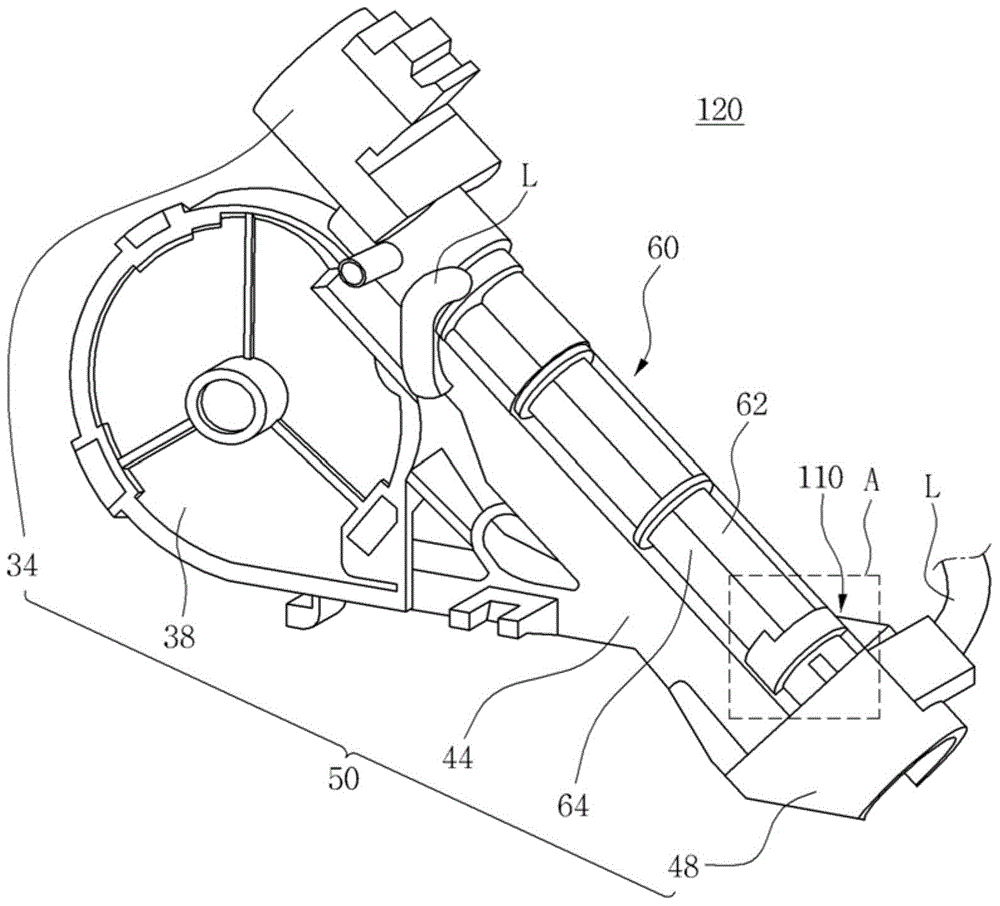

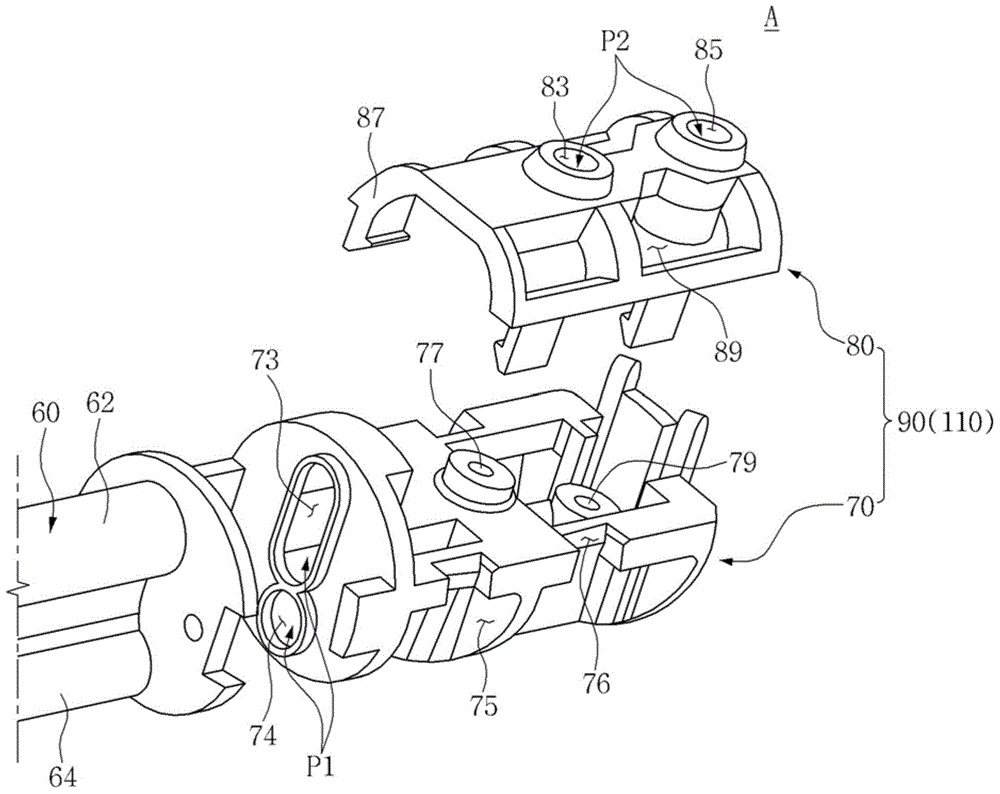

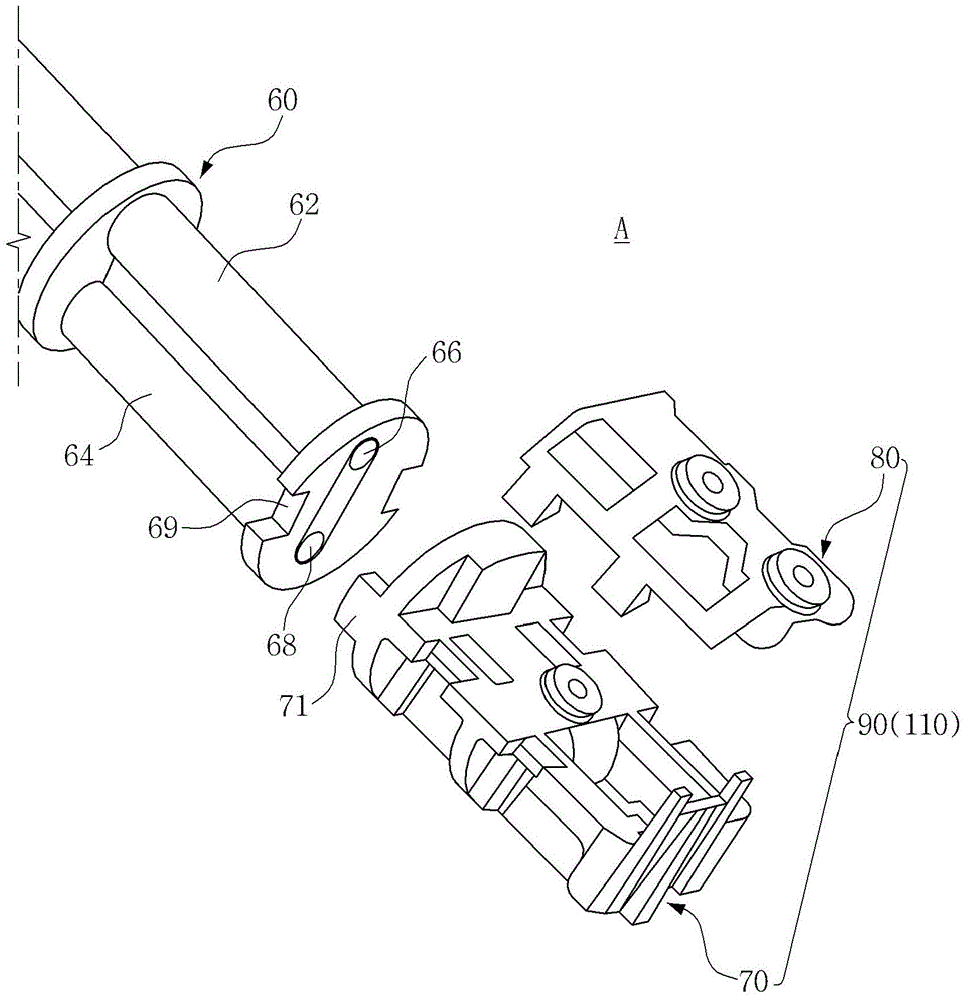

[0054] First, refer to Figure 1 to Figure 7 , further detailing the nozzle assembly in the warm water bidet according to the embodiment of the present invention.

[0055] figure 1 is a perspective view showing a nozzle assembly in a bidet bidet according to an embodiment of the present invention.

[0056] refer to figure 1 , the nozzle assembly 120 according to the embodiment of the present invention is equipped with Figure 8 in the warm water bidet 140. The nozzle assembly 120 includes an operation part 50 , a barrel part 60 and a nozzle module 110 inside the warm water bidet 140 . To briefly describe the nozzle assembly 120 , the operation part 50 is located around the cylinder part 60 and fixed on the cylinder part 60 .

[0057] The operation portion 50 is positioned between one end and the other end of the cylindrical portion 60 to support the cylindrical portion 60 . The said cylinder part 60 is arrange|positioned in one direction in the bidet 140, and has one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com