Air intake passage injection type charged gasoline engine high-efficiency combustion chamber

A technology of port injection and combustion chamber, applied in combustion engine, cylinder, cylinder head, etc., can solve the problem of unreasonable ratio of key parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with accompanying drawing, the present invention will be further described.

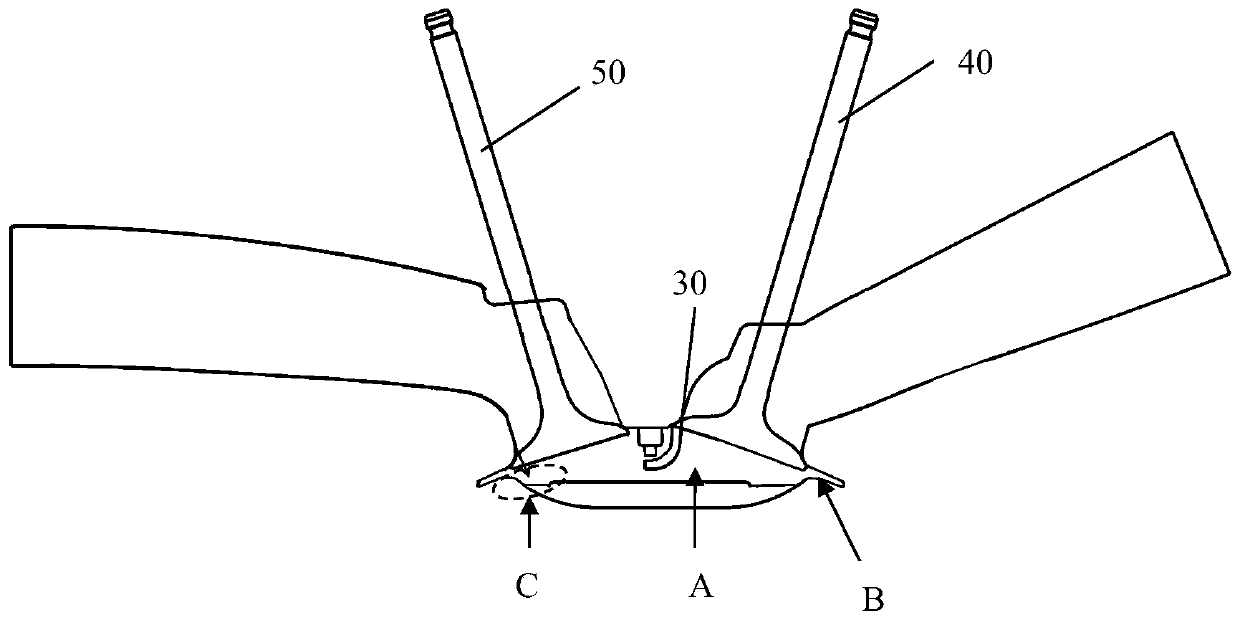

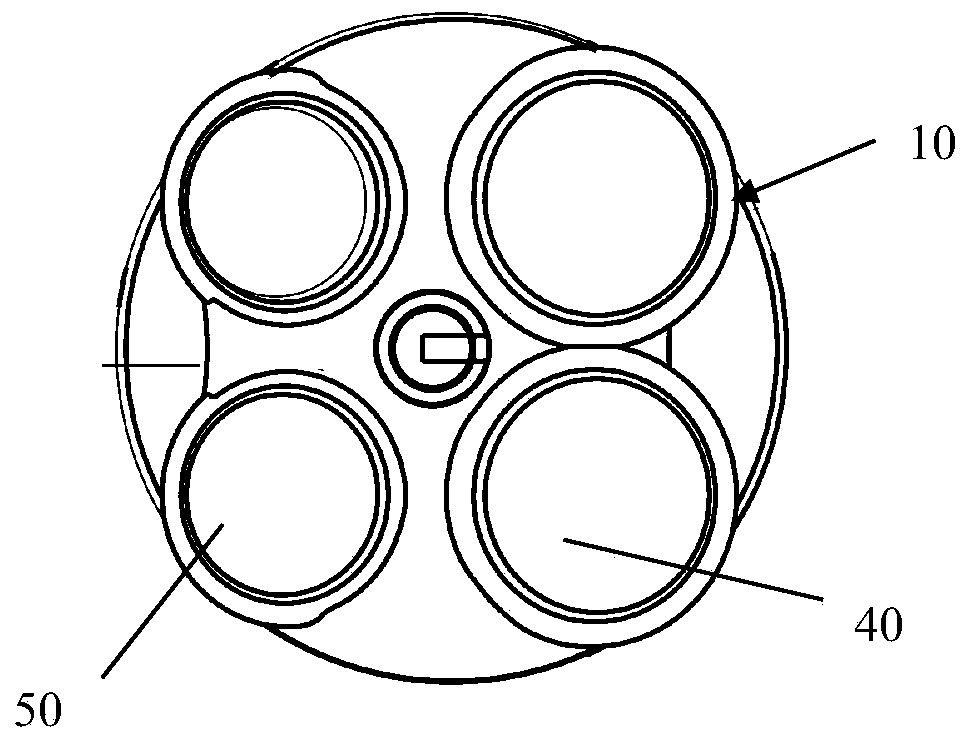

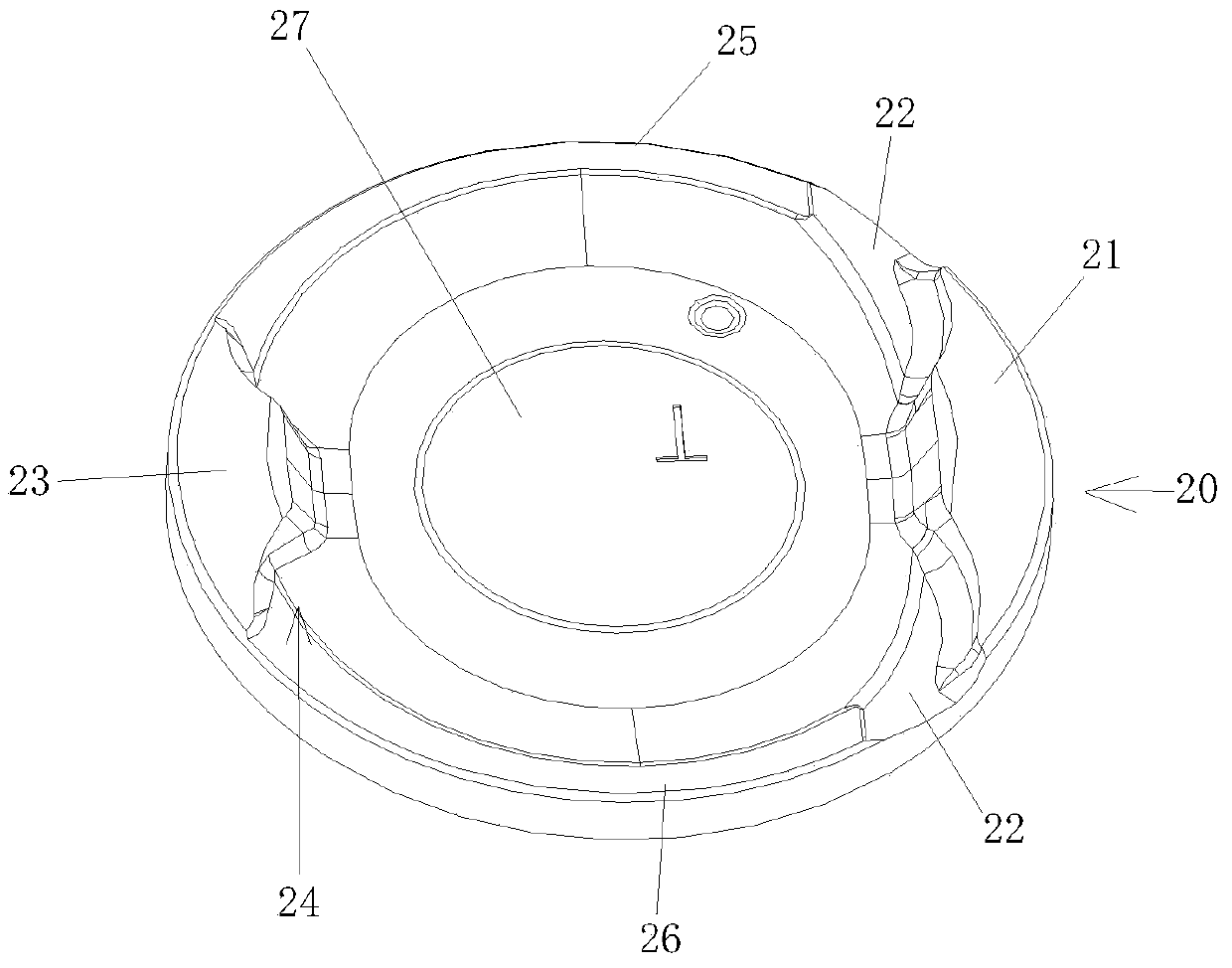

[0013] A high-efficiency combustion chamber of an intake port injection type supercharged gasoline engine, comprising a cylinder head below the dome 10 of the combustion chamber, above the top surface of the piston 20, and a cylinder barrel between the two enclosed and closed to form a combustion chamber cavity area A. An intake valve 40, an exhaust valve 50 and a spark plug 30 are provided, and the intake valve 40 and the exhaust valve 50 connected from the cylinder head to the cavity area A of the combustion chamber are characterized in that: the intake side and the exhaust side are respectively provided There are oblique squeeze zones B and C, and the squeeze gaps are both 0.9 to 1.1mm.

[0014] The preferred scheme is that the radial width of the air intake oblique squeeze area B is 11-13 mm, and the radial width of the exhaust side oblique squeeze area C is 8-11 mm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth of depression | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com