Cylinder end with multi-spherical surface combustion chamber and gasoline engine thereof

A combustion chamber and cylinder head technology, applied in combustion engines, internal combustion piston engines, cylinders, etc., can solve the problems of not being able to adapt to the use of spherical combustion chambers, affecting the normal operation of spherical combustion chambers, affecting the normal operation of gasoline engines, etc. Air, improve cooling effect, reduce deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

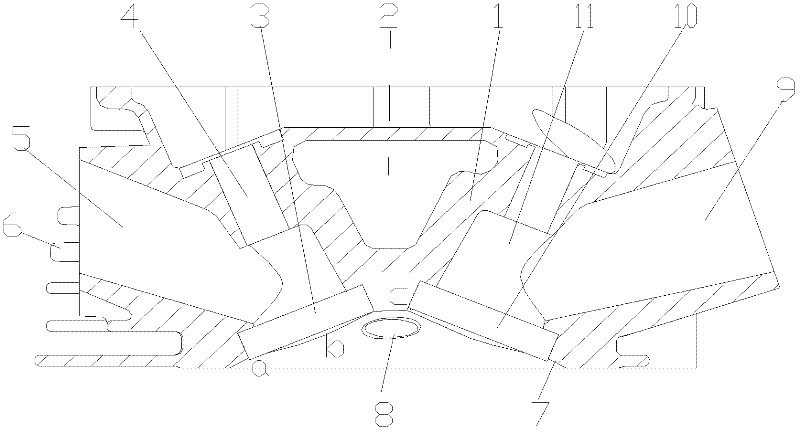

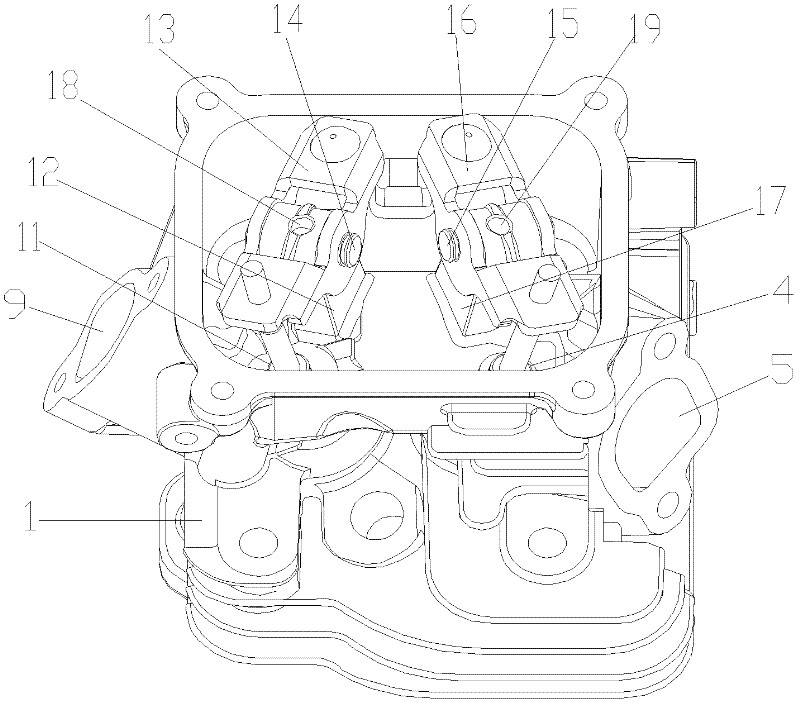

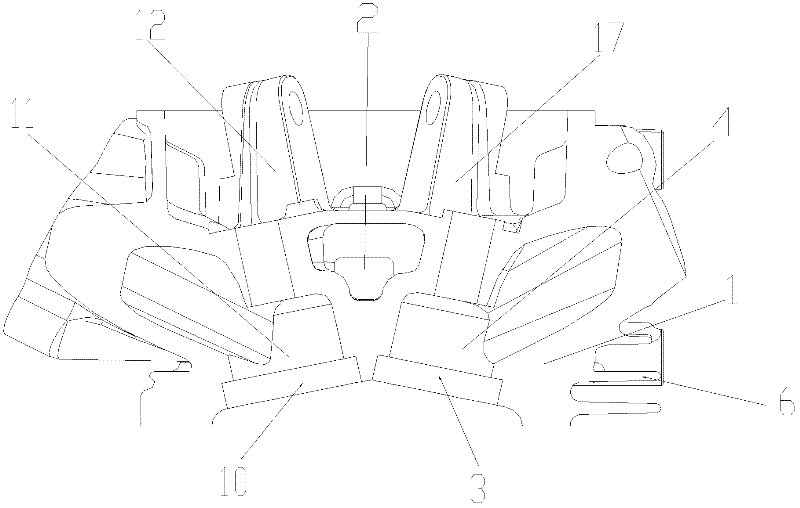

[0024] figure 1 It is a structural schematic diagram of the cylinder head combustion chamber of the present invention, figure 2 It is a schematic diagram of the arrangement structure of the cylinder head rocker arm of the present invention, image 3 It is a schematic diagram of the arrangement structure of the rocker seat of the present invention, Figure 4 It is a cross-sectional view of the cooperation between the rocker shaft and the rocker seat, as shown in the figure: the cylinder head of the multi-spherical combustion chamber of the present embodiment includes a cylinder head body 1 and an air intake passage 9 arranged on the cylinder head body, an exhaust gas The channel 5 and the spark plug installation hole 8, the combustion chamber surface 7 is formed inside the cylinder head body 1, and the combustion chamber surface is formed by three spherical surfaces tangent to each other from the bottom to the top, respectively spherical surface Ia, spherical surface IIb and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com