Liquid foundation raw material mixing equipment for cosmetic production

A technology of mixing equipment and liquid foundation, which is applied in mixers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of blockage, reduce the mixing rate of liquid foundation raw materials, etc., so as to improve the mixing rate and save halfway downtime. The effect of filling, avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

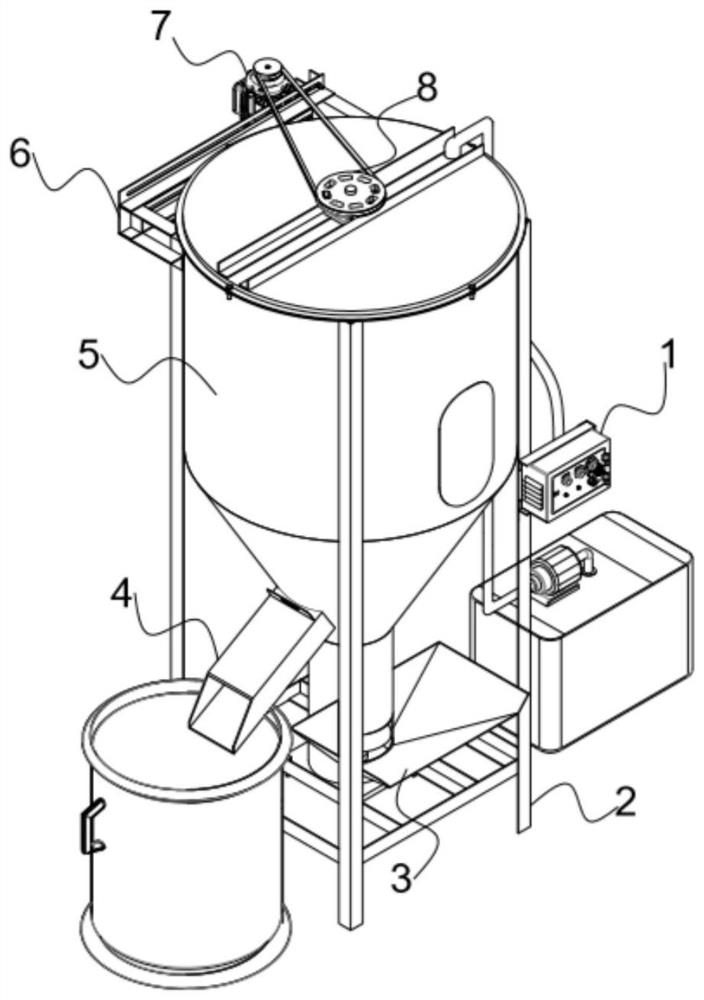

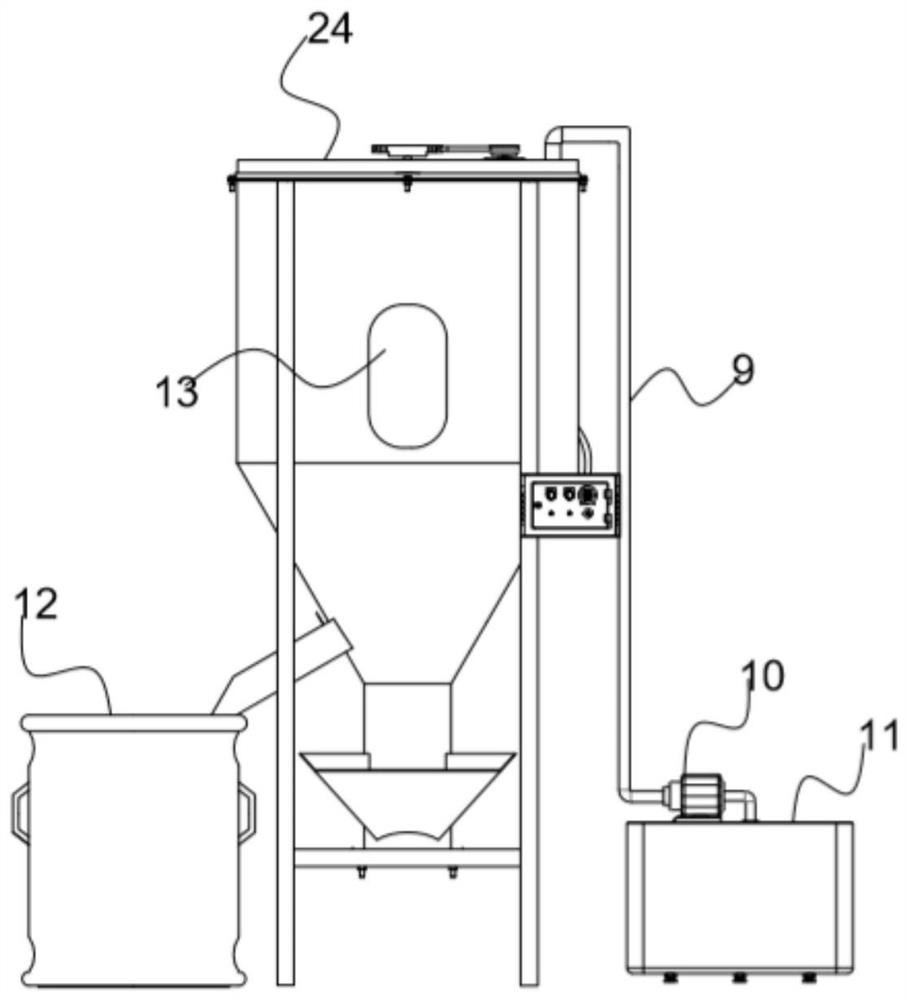

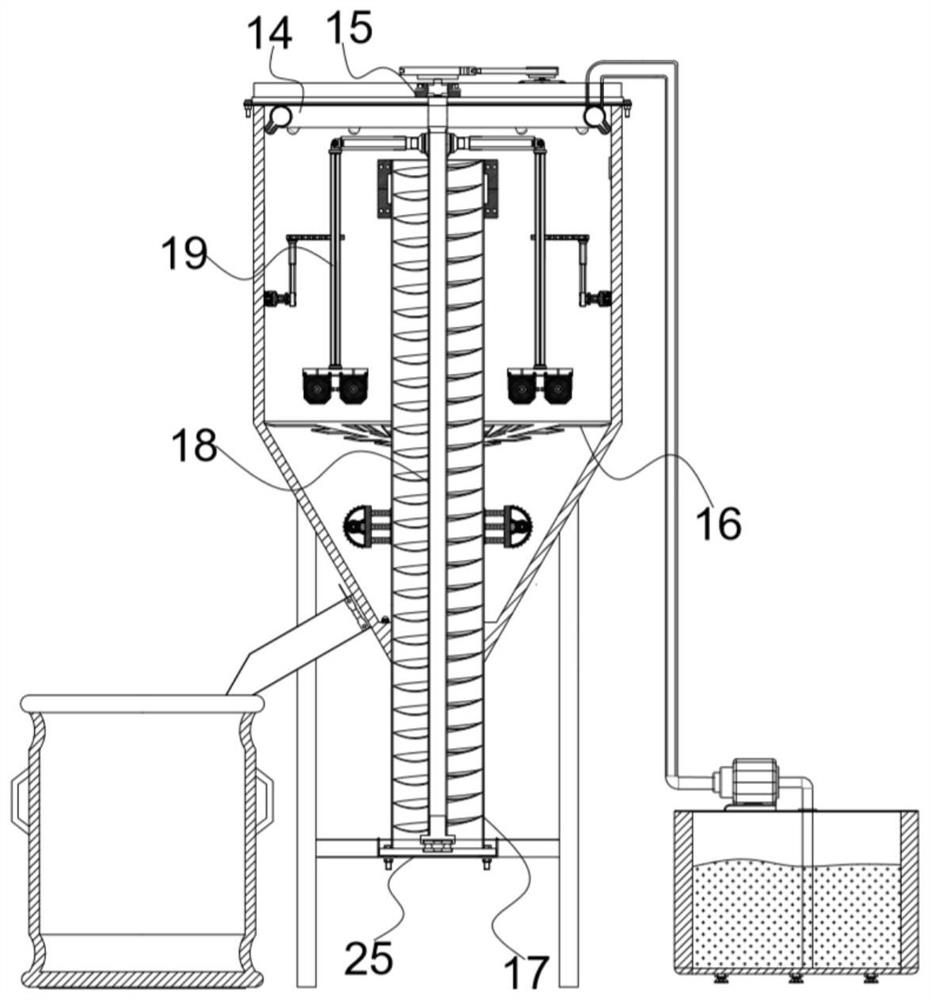

[0030] Example: see attached Figure 1-6 , the present invention provides a technical solution: a liquid foundation raw material mixing equipment for cosmetic production, including a shell 5 with a conical bottom, and an agitating assembly and an oscillating assembly arranged in the inner cavity of the shell 5, wherein the shell 5 The top end is provided with an opening and is sealed with an upper end cover 24. The shell 5 is set on the workbench through the support frame 2. The top of one side of the support frame 2 is fixedly welded with an attachment frame 6. A motor 7 is installed on the attachment frame 6. The output of the motor 7 The end is driven by a belt to connect the synchronous wheel 8 located at the top of the housing 5, the center of the bottom end surface of the synchronous wheel 8 is welded with a conveying assembly located in the inner cavity of the housing 5, and the bottom end of the conveying assembly protrudes from the bottom of the housing 5 and is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com