Oil Drilling Drill String Online Monitoring System and Fault Diagnosis Method

A technology of fault diagnosis and oil drilling, which is applied to the automatic control system of drilling, drilling equipment, measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

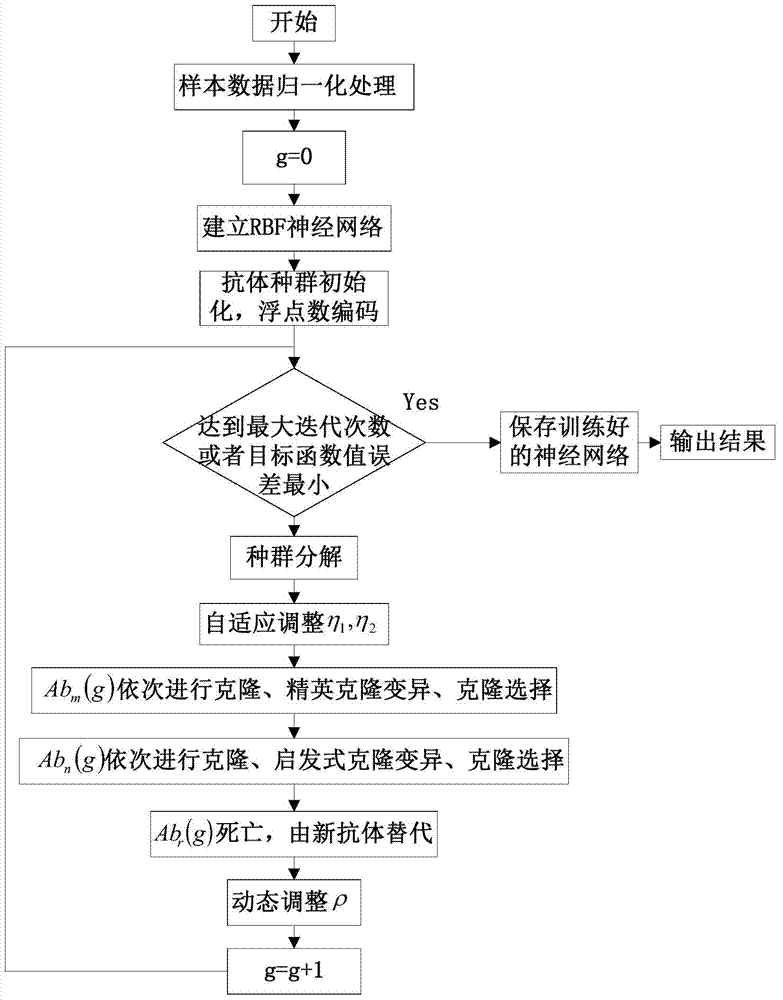

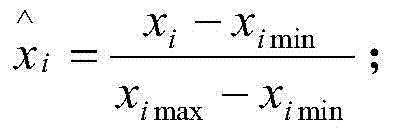

Method used

Image

Examples

Embodiment Construction

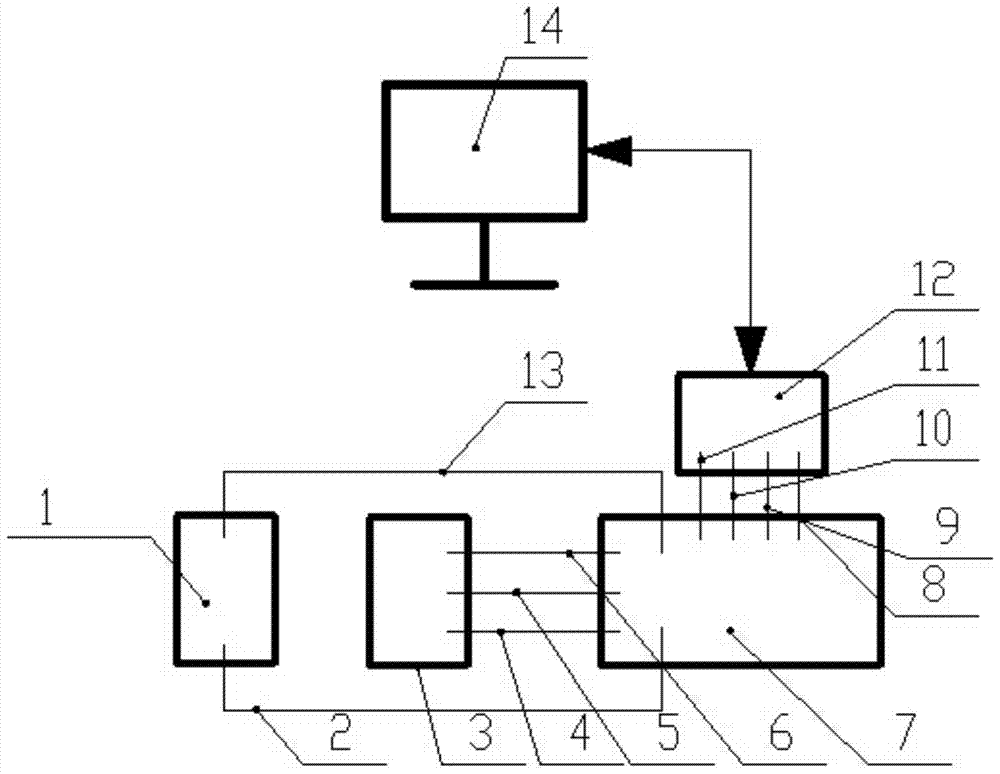

[0076] In order to express this patent more clearly, in conjunction with the attached figure 1 , 2 This patent is described further.

[0077] The oil drilling drill string drilling online monitoring system provided by the present invention includes a torque sensor 1, a torque sensor output ground wire 2, an acceleration sensor 3, a Z-axis signal output wire 4, a Y-axis signal output wire 5, and an X-axis signal output wire 6. PCB board 7, Bluetooth module power cord 8, Bluetooth module ground wire 9, Bluetooth module data download wire 10, Bluetooth module data output wire 11, Bluetooth module 12, torque sensor signal output wire 13, host computer 14.

[0078] The torque sensor 1 and the acceleration sensor 3 are not only connected to the drill string, but also connected to the PCB board 7 respectively. The torque output signal is formed between the torque sensor output ground wire 2 and the torque sensor signal output wire 13 , and is connected to the PCB board 7 .

[0079...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com