Device and method for simulating interaction between rock core and drilling fluid under drilling condition

A drilling fluid and core technology, applied in wellbore/well components, earthwork drilling, etc., can solve the problems of inability to simulate complex working conditions and formation pressure, and achieve the effect of simple structure, reasonable design and reliable principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

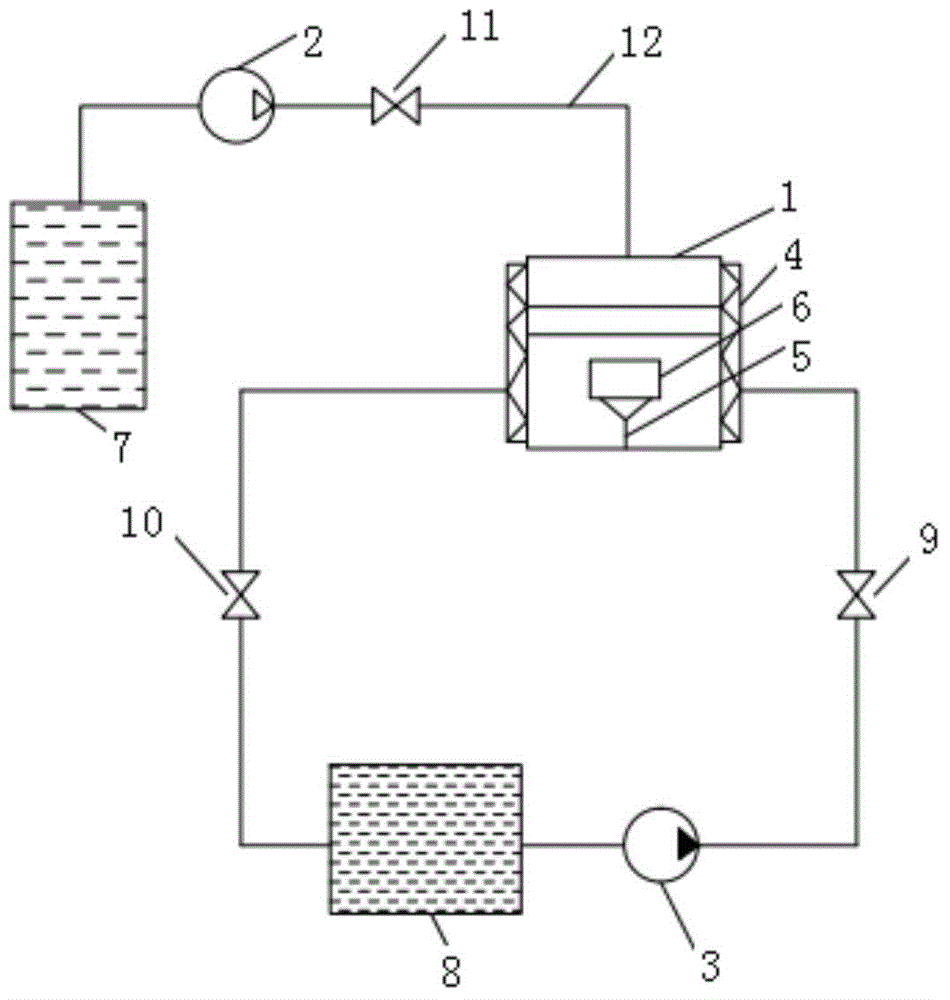

[0018] As a first aspect of the present invention, a device for simulating the interaction between core and drilling fluid under drilling conditions is provided, including: a piston container 1, including a hydraulic chamber and a core chamber; an advection pump 2, connected with the hydraulic chamber, for To apply working pressure to the core chamber; the displacement circulating pump 3 is connected to the core chamber for pumping drilling fluid into the core chamber and forming a circulating flow. Preferably, the device further includes: a bracket 5 installed in the core chamber for placing the core 6 to be soaked.

[0019] Among them, the piston container 1 is divided into two parts by the piston in it, one part is a hydraulic chamber, which is connected with the advection pump 2, and the fluid is injected through the advection pump 2 to realize pressure loading and adjustment; the other part is for holding the rock core to be soaked ( core) and core chamber for drilling fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com