Hydraulic type directional fracturing equipment

A directional fracturing and hydraulic technology, applied in hydraulic mining, earth-moving drilling, special mining, etc., can solve problems such as drilling damage, affecting mining progress, drilling, etc., and achieve uniform force on the cylinder head, which is conducive to popularization and implementation. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

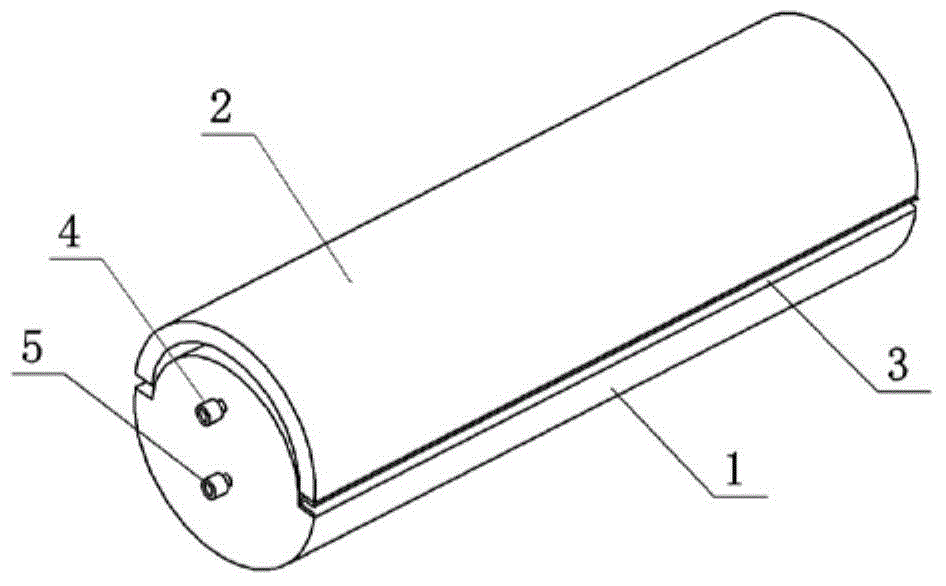

[0011] join figure 1 , the hydraulic directional fracturing equipment includes a horizontal cylinder body 1 and a cylinder head 2, the cylinder body 1 and the cylinder head 2 form a cylindrical structure. All the joint surfaces between the cylinder head 2 and the cylinder body 1 are sealed 3 with a flexible connection layer. Between the cylinder head 2 and the cylinder body 1 are provided an upper stepped surface and a lower stepped surface 7 which cooperate with each other. The flexible connection layer 3 is arranged between the upper and lower step surfaces.

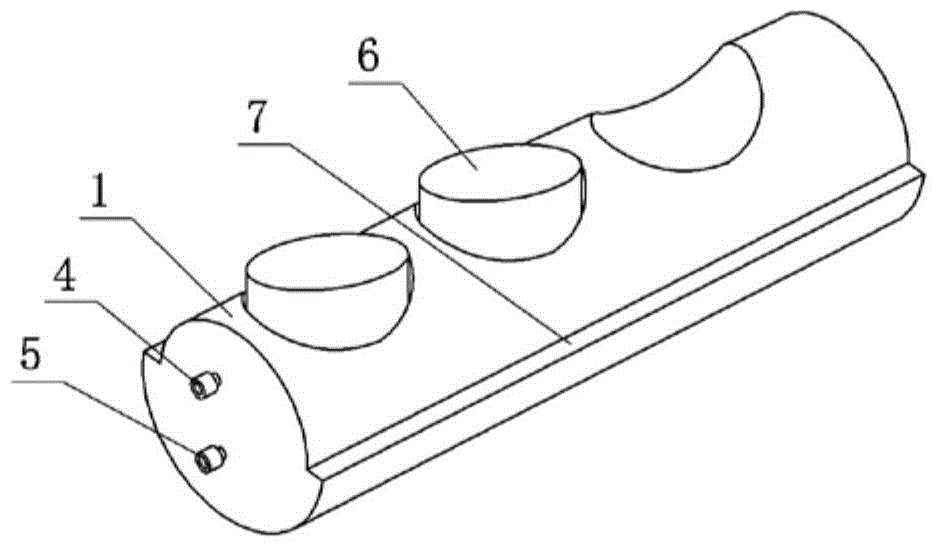

[0012] join figure 2 : A plunger hole is arranged radially on the side opposite to the cylinder body 1 and the cylinder head 2, and plungers 6 are installed respectively. The orifice of the plunger hole is provided with a sealing structure to prevent the plunger from being pulled out. The upper end of the plunger 6 is connected to the inner wall of the cylinder head 2 .

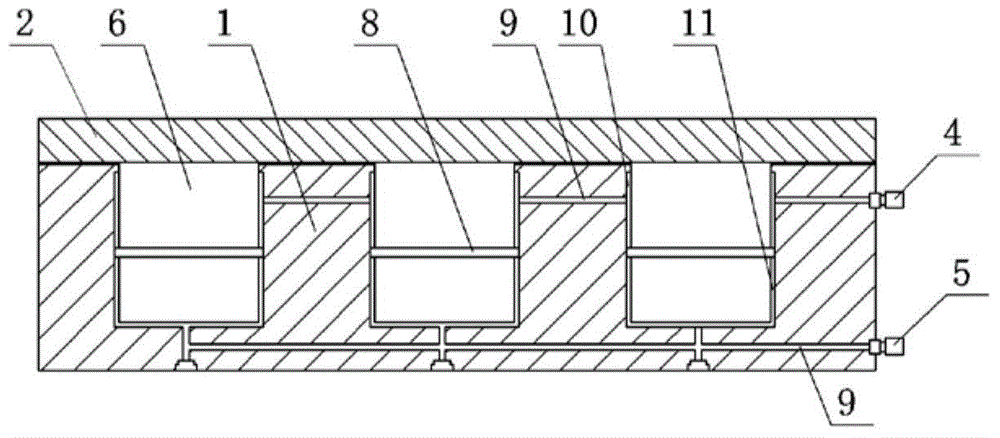

[0013] join image 3 : The middle sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com