Thrust bearing for steering axle of commercial vehicle

A thrust bearing and steering axle technology, applied in the field of rolling bearings, can solve the problems affecting the installation accuracy and performance of the thrust bearing, reducing the service life of the bearing, and large bearing end face swing, so as to prevent grease leakage, improve the bearing life, and improve the use of Effects of longevity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further explained below in conjunction with accompanying drawing.

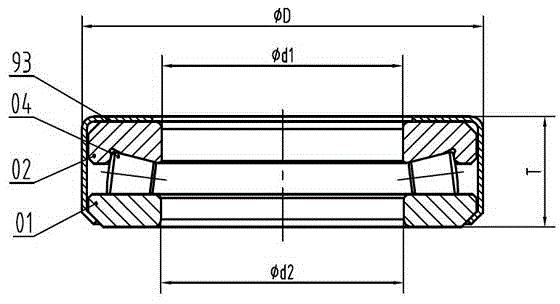

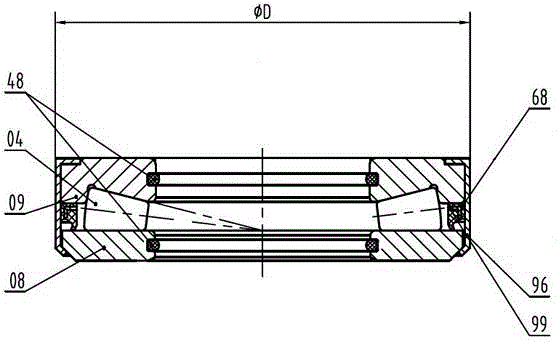

[0020] like figure 2 shown. The thrust bearing for a commercial vehicle steering axle of the present invention includes an outer cover 96, a shaft ring 09, a seat ring 08, a rolling element 04 and a cage. The outer diameter of the thrust bearing is ΦD30-100mm, and the cage can be a stamped steel cage or a nylon cage. When the full roller, full ball or damping bearing structure is used, the cage is also unnecessary. Wherein, the inner diameter of the seat ring 08 has a seat ring annular sealing ring 48, and the seat ring annular sealing ring 48 is an annular rubber sealing ring. The inner diameter of the shaft ring 09 is a shaft ring annular sealing ring 48, and the shaft ring annular sealing ring 48 is an annular rubber sealing ring. There is a step at the chamfer of the large end surface of the shaft ring 09, which is convenient for the edge of the outer cover to fit o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com