Dual-hydraulic cylinder driven hydraulic locking shaft sleeve performance testing platform

A technology of dual hydraulic cylinders and a test platform, which is applied in the field of hydraulic control, can solve problems such as shaft sleeve fatigue cracks, and achieve the effects of energy saving, material saving, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

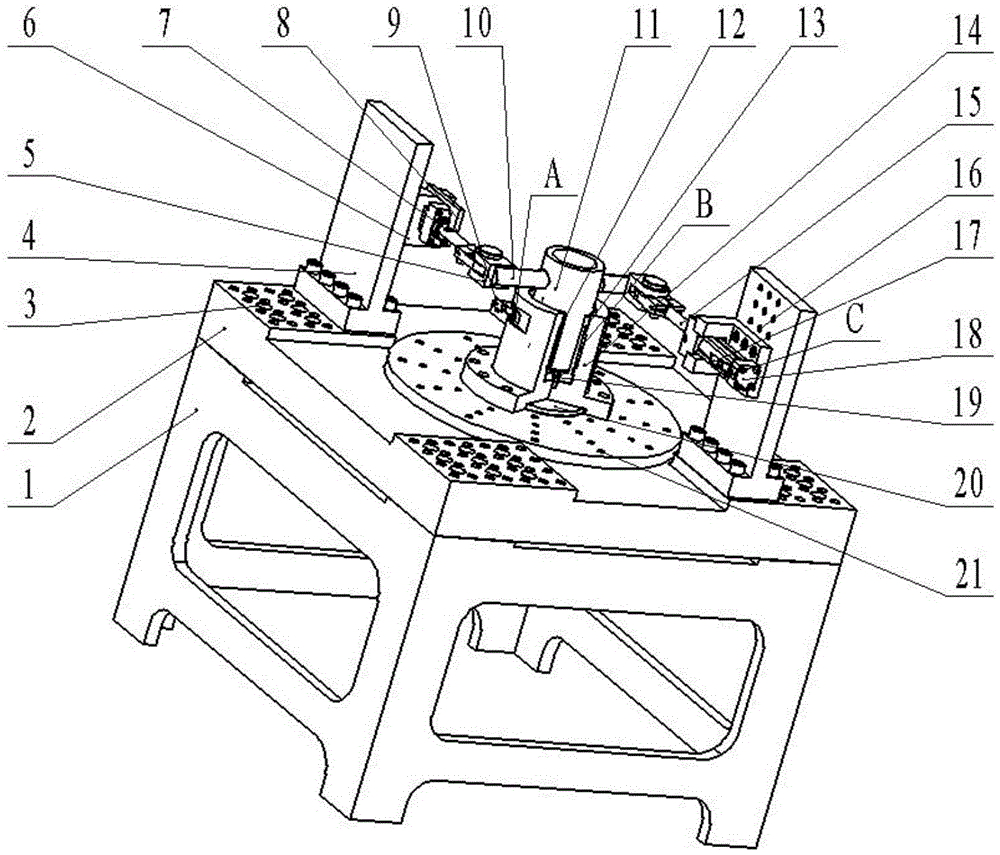

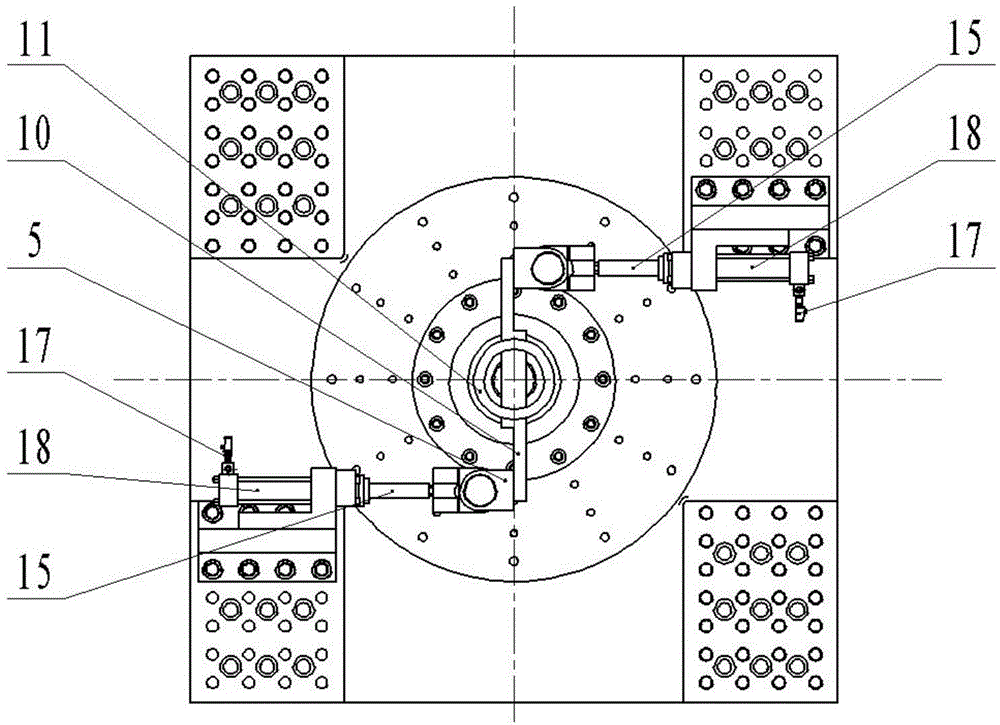

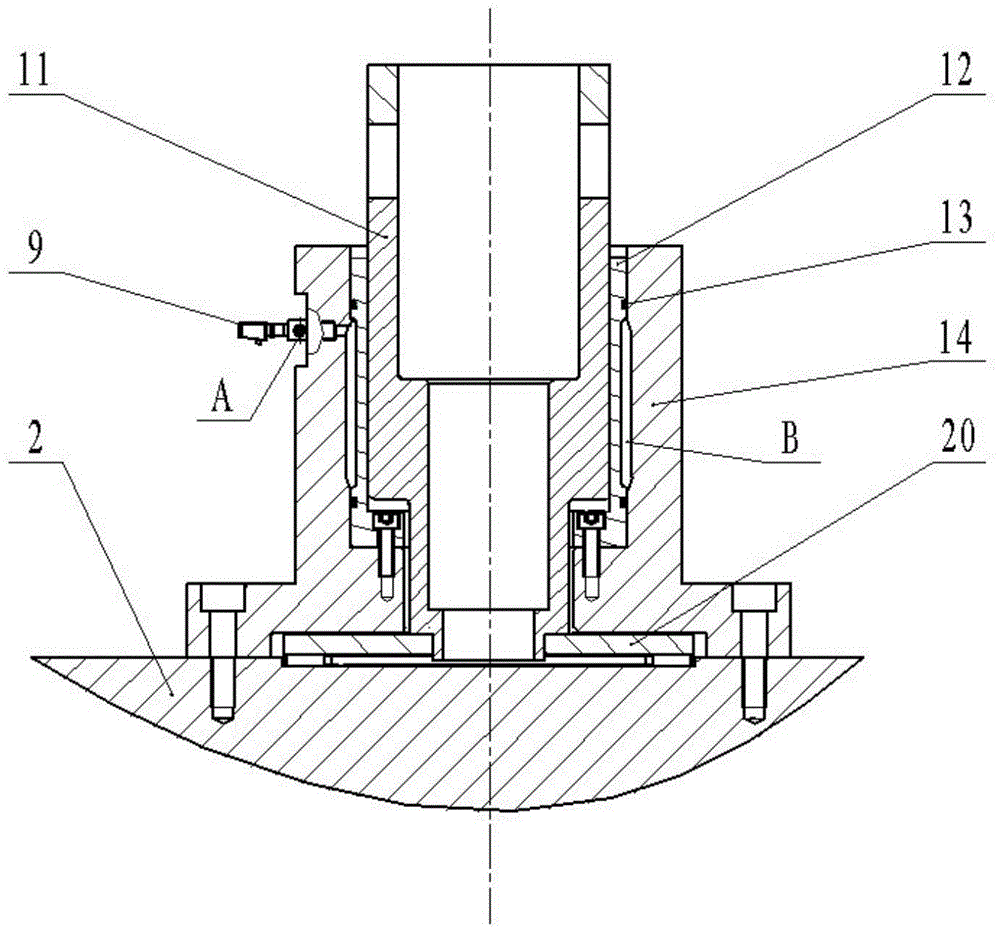

[0032] like figure 1 As shown, the present invention provides a dual-hydraulic cylinder-driven hydraulic locking bushing performance test platform, which is characterized in that: the platform mainly includes a support 1, a mounting table 2, a hydraulic cylinder bracket position adjustment pin hole 3, and a hydraulic cylinder bracket 4 And hydraulic cylinder, hydraulic cylinder bracket 6, travel switch contact 7, travel switch 8, electronic display pressure gauge 9, torsion bar 10, rotating shaft 11, hydraulic locking sleeve 12, O-ring 13, hydraulic locking shaft Sleeve 14, hydraulic cylinder bracket height adjustment screw hole 16, electronic display pressure gauge 17, hydraulic cylinder block 18, hydraulic locking sleeve fixing screw 19, thrust bearing 20, flange screw hole 21, pressure oil chamber inlet and outlet A. Pressure oil cavity B, hydraulic cylinder push stroke inlet and outlet port C and hydraulic cylinder return stroke inlet and outlet port D.

[0033] The inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com