Reinforced concrete shell fire resistance testing system

A technology of reinforced concrete and test system, applied in the direction of material thermal development, etc., can solve problems such as result distortion, data inconsistency, failure to consider the impact of fire resistance, etc., and achieve the effect of high test efficiency and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

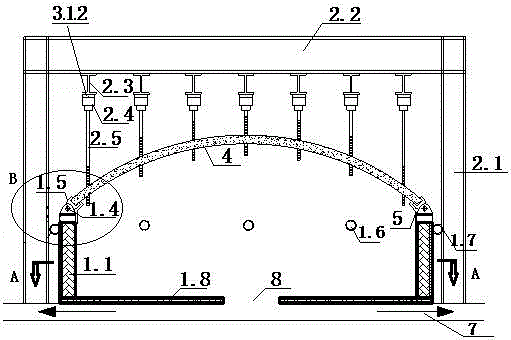

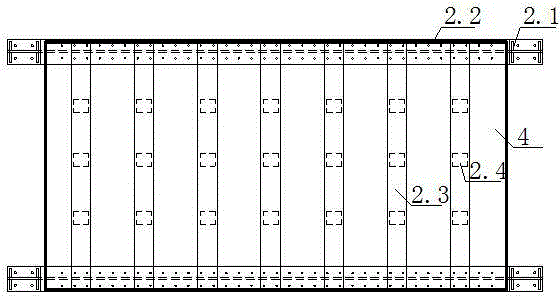

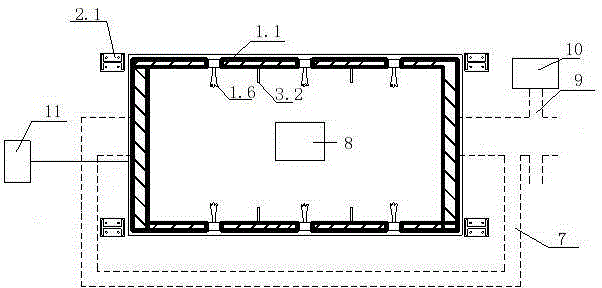

[0025] like Figures 1 to 5 As shown, the reinforced concrete shell fire resistance test system includes a test furnace device, a loading device and a control and data acquisition device. The test furnace device includes a furnace body (1.1), a trough support (1.5), and an integrated burner (1.6) , the oil supply pipeline (1.7) and the furnace floor (1.8), the cross-section of the channel support (1.5) is a channel steel structure, the width of the notch matches the thickness of the reinforced concrete shell (4), and the reinforced concrete The shell (4) snaps into the notch, the nozzle of the integrated burner (1.6) is set towards the inside of the furnace body (1.1), the oil inlet hole of the integrated burner (1.6) is connected with the oil supply pipe (1.7), and the oil supply The pipeline (1.7) is set outside the furnace body (1.1) and surrounds the furnace body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com