Preparation method of transparent pattern headphone cable and product

A headphone wire and pattern technology, which is applied in the field of preparation of transparent pattern earphone wires, can solve problems such as poor skin affinity, achieve good touch, avoid harmful components, and facilitate identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

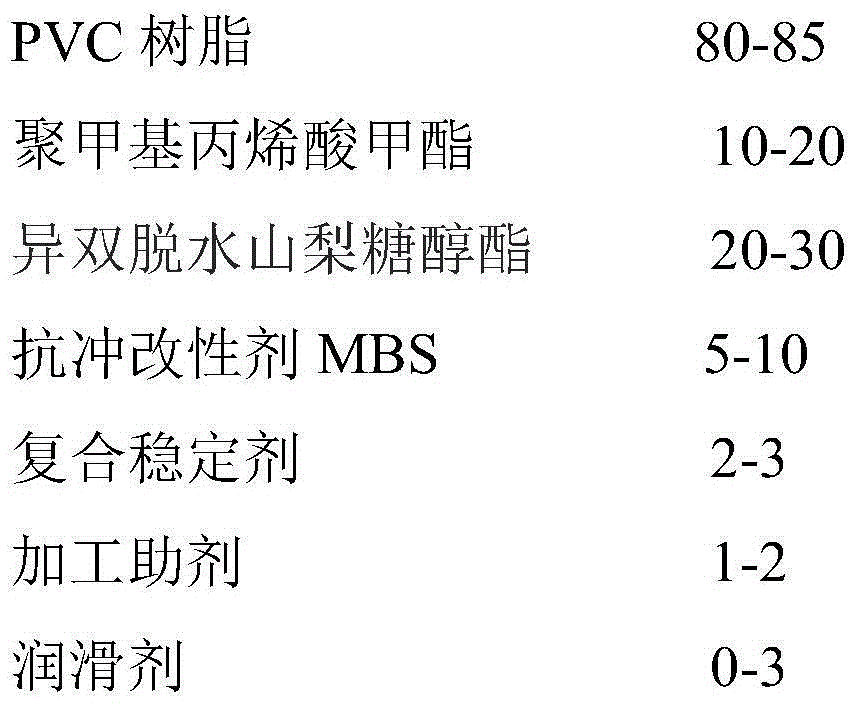

Embodiment 1

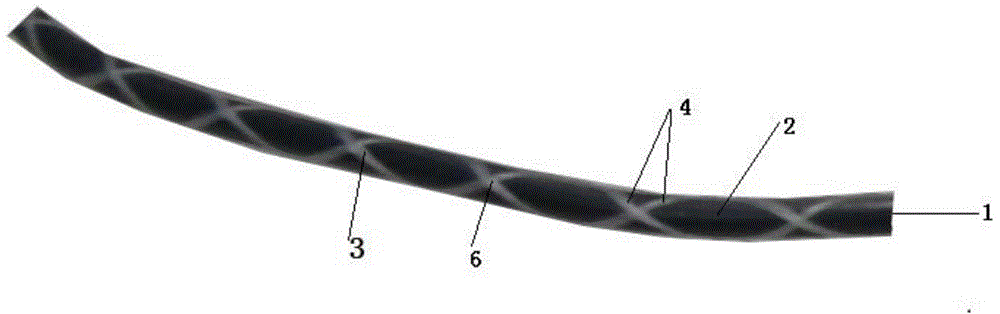

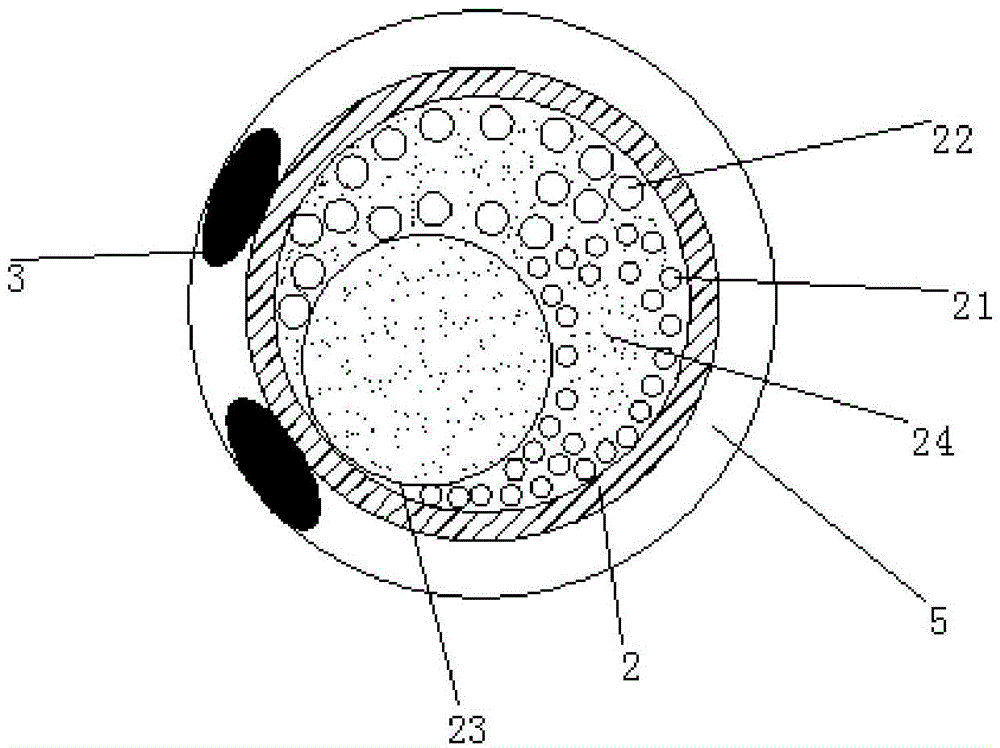

[0034] see Figure 1-2 , the preparation method of the transparent pattern earphone cable provided by the present invention, it comprises the steps:

[0035] (1) Preparation of the inner wire: After the first wire and the second wire are interspersed with the yarn and spirally intertwined together, they are twisted together with the fiber bundle, and then an insulating outer layer is formed on the outside, and the wire is extruded Plasticized molding makes the insulating outer layer closely adhere to the surface of the wire and the yarn, and its thickness is 0.2-1mm;

[0036] (2) Prepare fluorescent cloth tape: apply fluorescent paint on gauze with a thickness of 0.2-0.5 mm, and after natural drying, cut the fluorescent cloth tape into a long cloth tape with a width of 0.5-1.5 mm;

[0037] (3) Winding pattern tape: two strands of fluorescent cloth tapes in step (2) after cutting are cross-wound along the surface of the inner line in step (1) to form a pattern tape with severa...

Embodiment 2

[0054] The preparation method of the transparent patterned earphone cord and its products provided in this embodiment are basically the same as those in Example 1, the difference being that the preparation method of the transparent patterned earphone cord specifically includes the following steps:

[0055] (1) Preparation of the inner wire: After the first wire and the second wire are interspersed with the yarn and spirally intertwined together, they are twisted together with the fiber bundle, and then an insulating outer layer is formed on the outside, and the wire is extruded Plasticized molding makes the insulating outer layer closely adhere to the surface of the wire and the yarn, and its thickness is 0.2-1mm;

[0056] (2) Prepare fluorescent cloth tape: apply fluorescent paint on gauze with a thickness of 0.2-0.5 mm, and after natural drying, cut the fluorescent cloth tape into a long cloth tape with a width of 0.5-1.5 mm;

[0057] (3) Winding pattern tape: two strands of...

Embodiment 3

[0066] The preparation method of the transparent pattern earphone cord and its products provided in this embodiment are basically the same as those in Examples 1 and 2, the difference being that the preparation method of the transparent pattern earphone cord specifically includes the following steps:

[0067] (1) Preparation of the inner wire: After the first wire and the second wire are interspersed with the yarn and spirally intertwined together, they are twisted together with the fiber bundle, and then an insulating outer layer is formed on the outside, and the wire is extruded Plasticized molding makes the insulating outer layer closely adhere to the surface of the wire and the yarn, and its thickness is 0.2-1mm;

[0068] (2) Prepare fluorescent cloth tape: apply fluorescent paint on gauze with a thickness of 0.2-0.5 mm, and after natural drying, cut the fluorescent cloth tape into a long cloth tape with a width of 0.5-1.5 mm;

[0069] (3) Winding pattern tape: two strands...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com