A potting process method for high-density electrical connectors

A technology of electrical connectors and process methods, applied in the directions of connection, assembly/disassembly of contacts, circuit/collector parts, etc., can solve the problems of inability to transmit continuously and evenly, prone to cracks, and failure of potting, etc. Achieve the effect of improving assembly quality, reducing air bubbles, and ensuring high consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

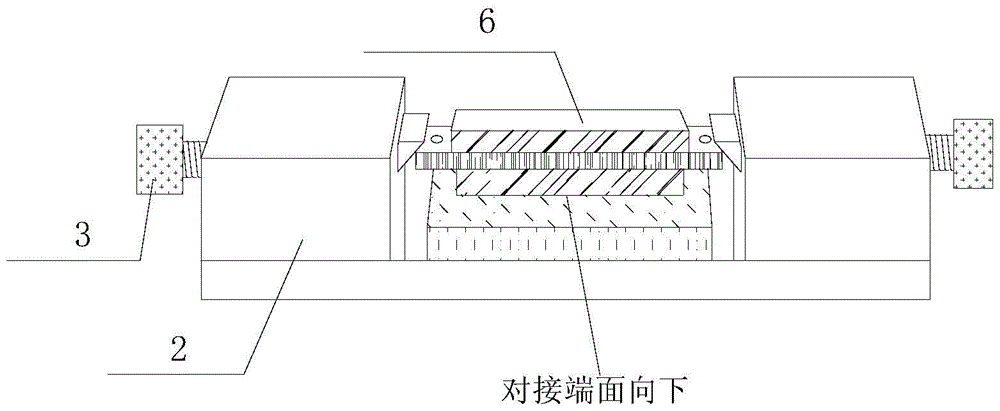

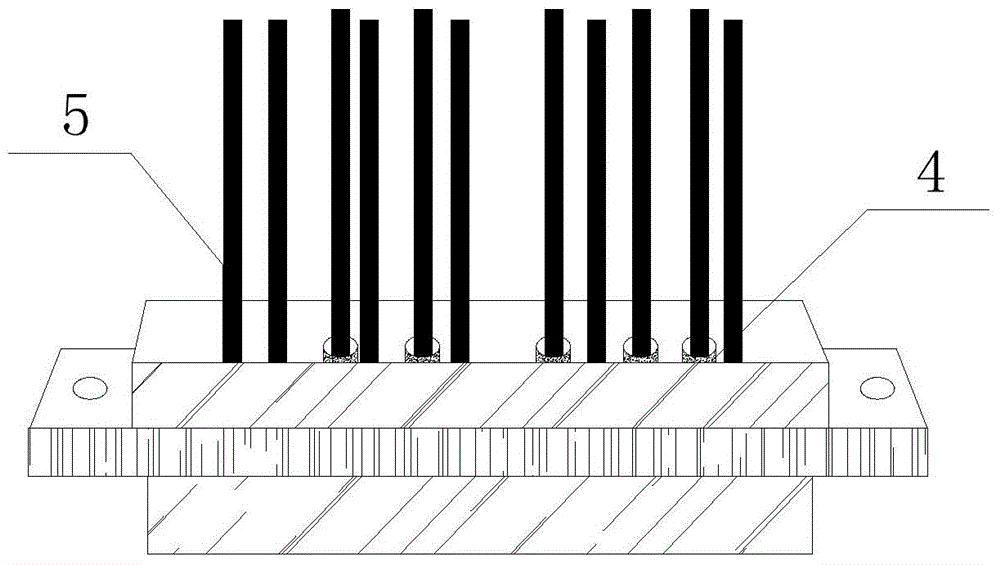

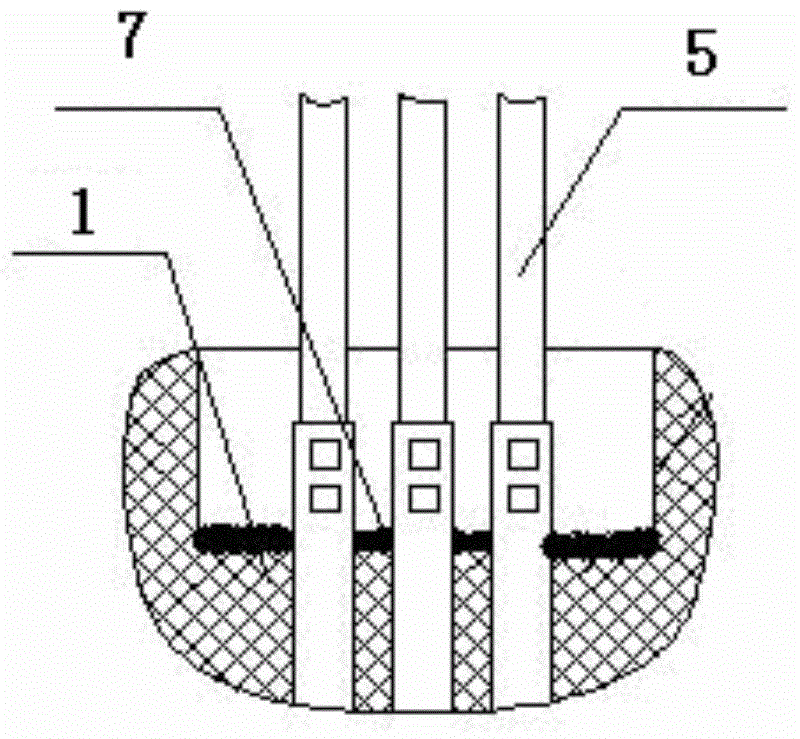

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0035] The invention can well fill the gap between pins of the high-density electric connector during potting by selecting potting glue with good fluidity. The way of primer is used to fix the terminal first, which is beneficial to the leveling of the terminal. After the terminal is leveled, the potting of the connector is carried out. Use the iron wire to pick up the potting glue that has been de-bubbled, and then use the defoaming air gun to blow the glue on the wire into the potting part. The wire moves along the horizontal gap of the terminal. Using the de-foaming air gun to blow the glue, this potting process can make the glue solution evenly pot the connector cavity layer by layer, so that there is no dead angle in the potting, and no unpotted cavity will affect the potting quality.

[0036] The specific implementation steps of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com