Semi-controlled intelligent high-power arc-free DC bus contact device

A technology of DC bus and contact device, which is applied in the field of high-power DC switches, medium voltage and high-voltage high-power DC switches, and achieves the effect of avoiding the risk of thermal hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

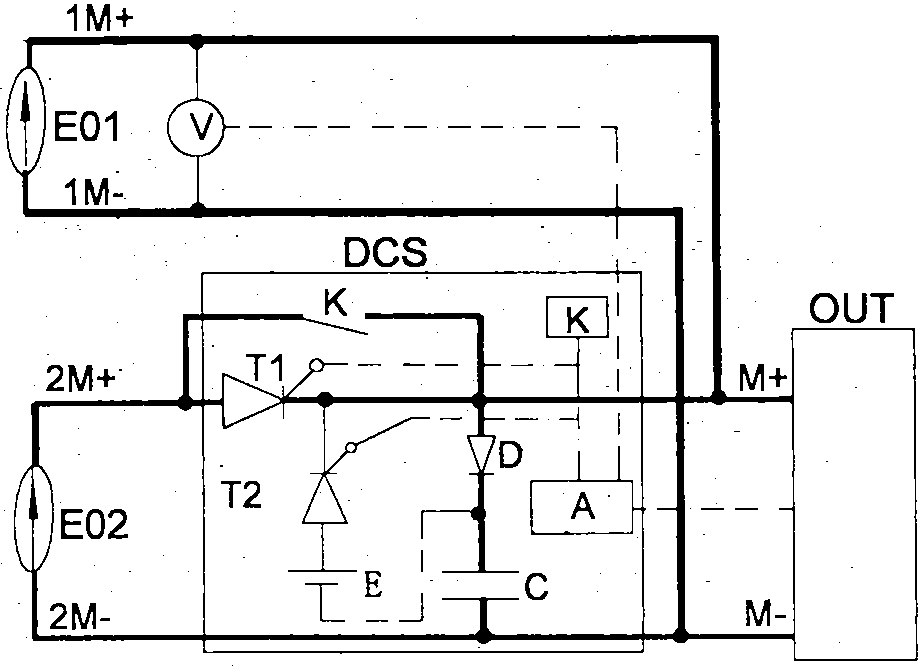

[0011] like image 3 As shown, the semi-controlled intelligent high-power arc-free DC bus contact device DCS is composed of a controller A, a contacted main switch K, a non-contact main switch T1 and its dynamic reverse bias control circuit. Its dynamic reverse bias control The circuit consists of a non-contact control switch T2, a voltage source E, a capacitor C and a diode D. The positive pole of T1 is connected with the input terminal of the K main contact and the positive pole (2M+) of the bus bar of the emergency DC power supply E02 in common. The positive pole (M+) of the diode D is connected in common, the negative pole of the diode D is connected with the positive pole of the capacitor C and the negative pole of the voltage source E in common, the positive pole of the voltage source E is connected with the positive pole of the non-contact control switch T2, and the negative pole of C is connected with the discharge bus. Negative (M-). The control poles of T1 and T2 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com