Ultrahigh-power servomotor

A servo motor, ultra-high power technology, applied in the field of servo motors, can solve the problems of inability to achieve high specific power, short-term peak overload, limited development of all-electric servo systems, and heavy servo motors, achieving small positioning torque and weakening. Obviously, the effect of increasing the winding coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

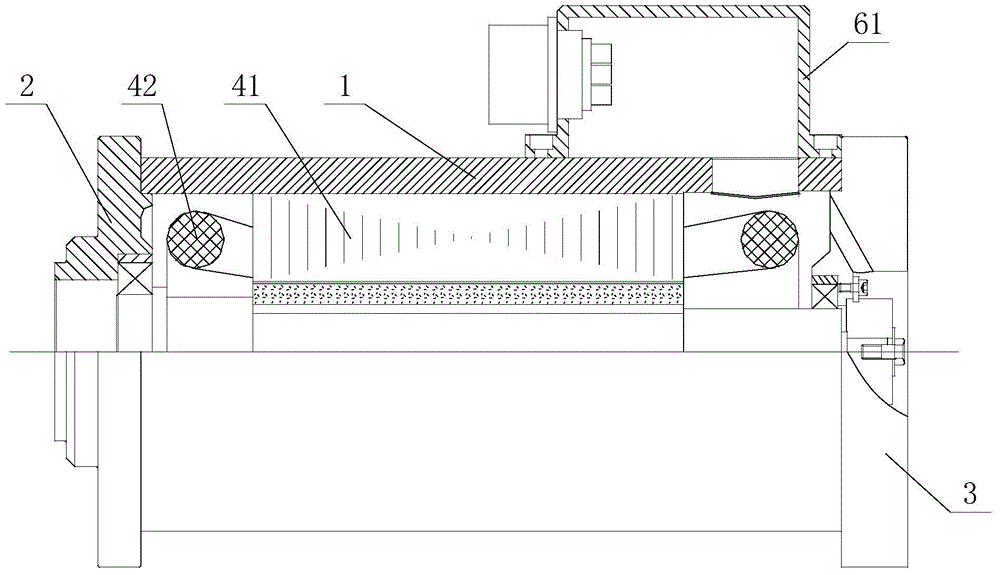

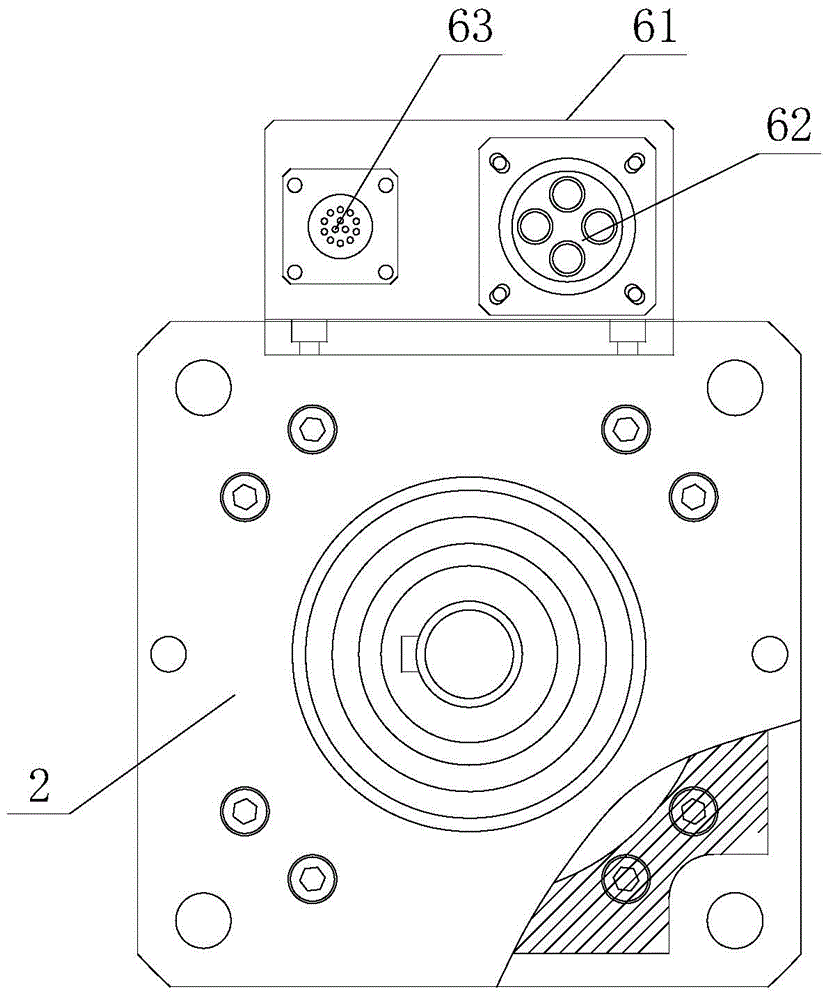

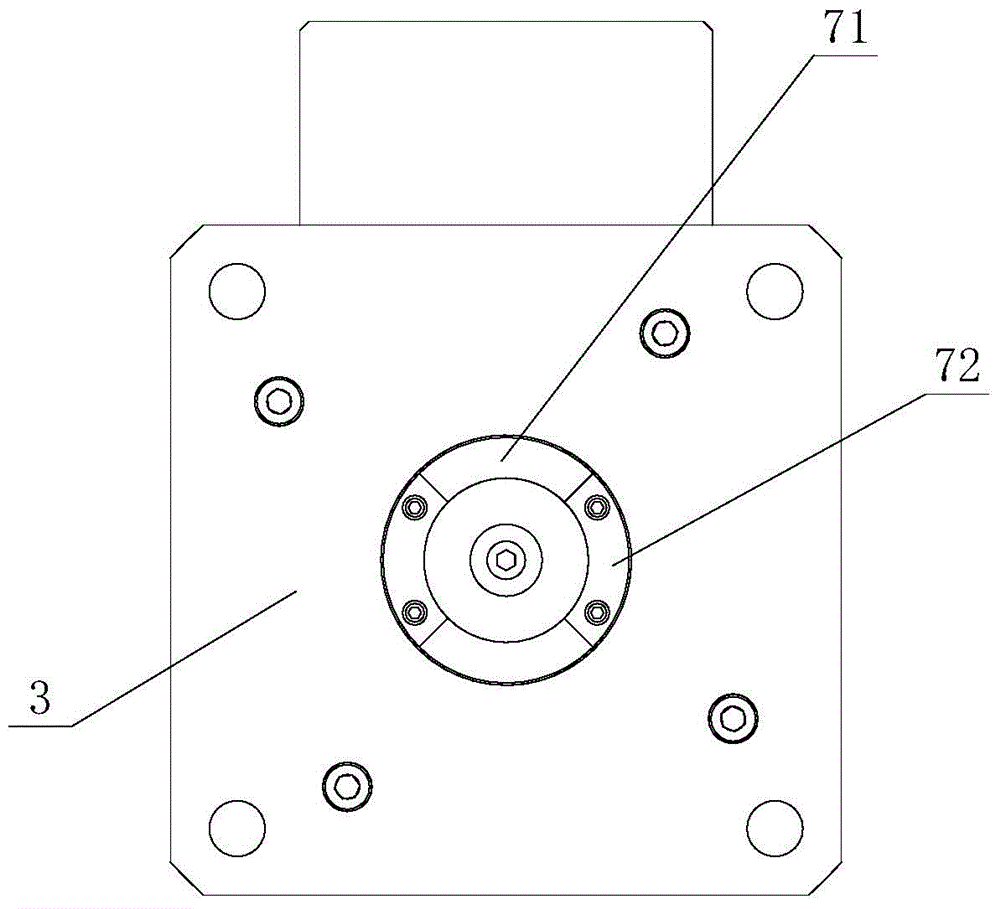

[0027] Such as figure 1 As shown, a 30KW class ultra-high power servo motor provided by the present invention includes a housing 1, a first end cover 2, a second end cover 3, a stator, a rotor, an electrical interface and a feedback element, the first end cover 2 and the second end cover The two end covers 3 are respectively located at both ends of the housing 1, the rotor is located inside the stator, the central axis of the stator is in line with the central axis of the stator, that is, the rotor and the stator are coaxially arranged, and the electrical interface is fixed on the outer surface of the housing 1 , the feedback element is fixed on the first end cover 2, and the feedback element is electrically connected with the electrical interface.

[0028] The stator includes an iron core 41 and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com