Ditcher cutterhead

A trenching machine and trenching knife technology, which is applied in the fields of farming equipment, agricultural machinery and equipment, and application, can solve the problems of difficulty in excavation, difficulty in processing parts, weak ability to open deep trenches, etc., and achieves easy repair and maintenance. The effect of high strength and strong ditching ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

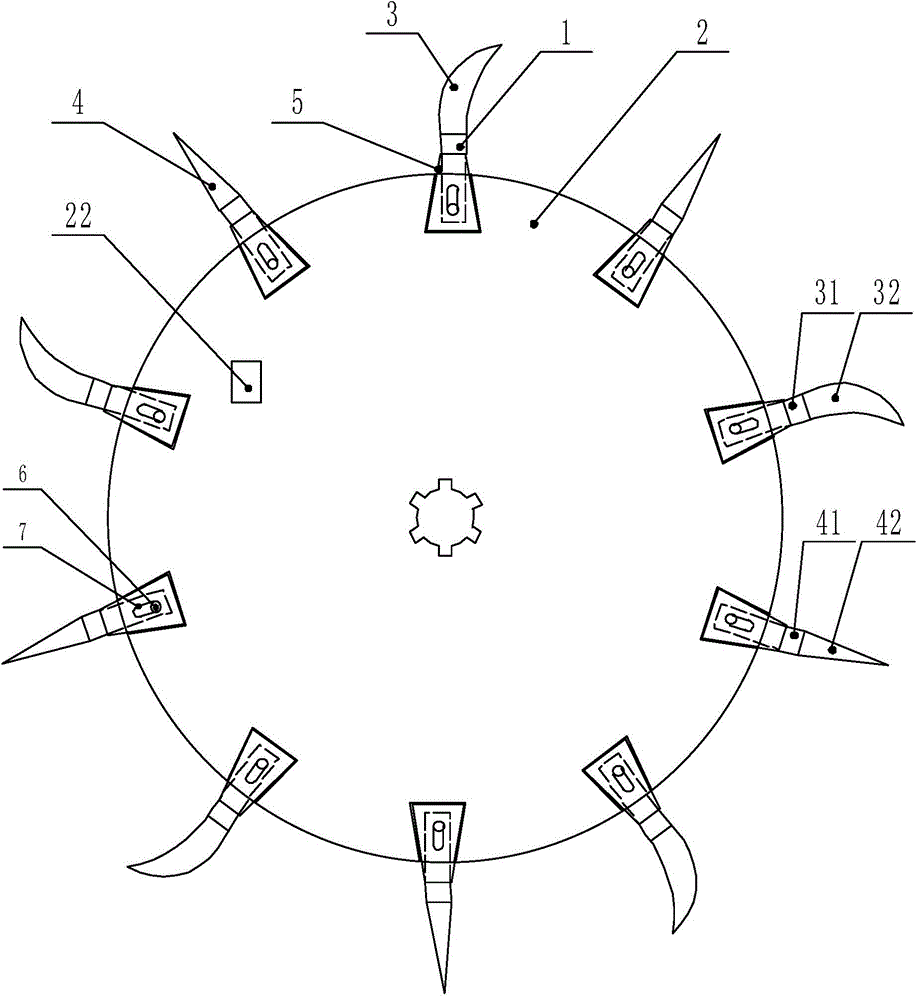

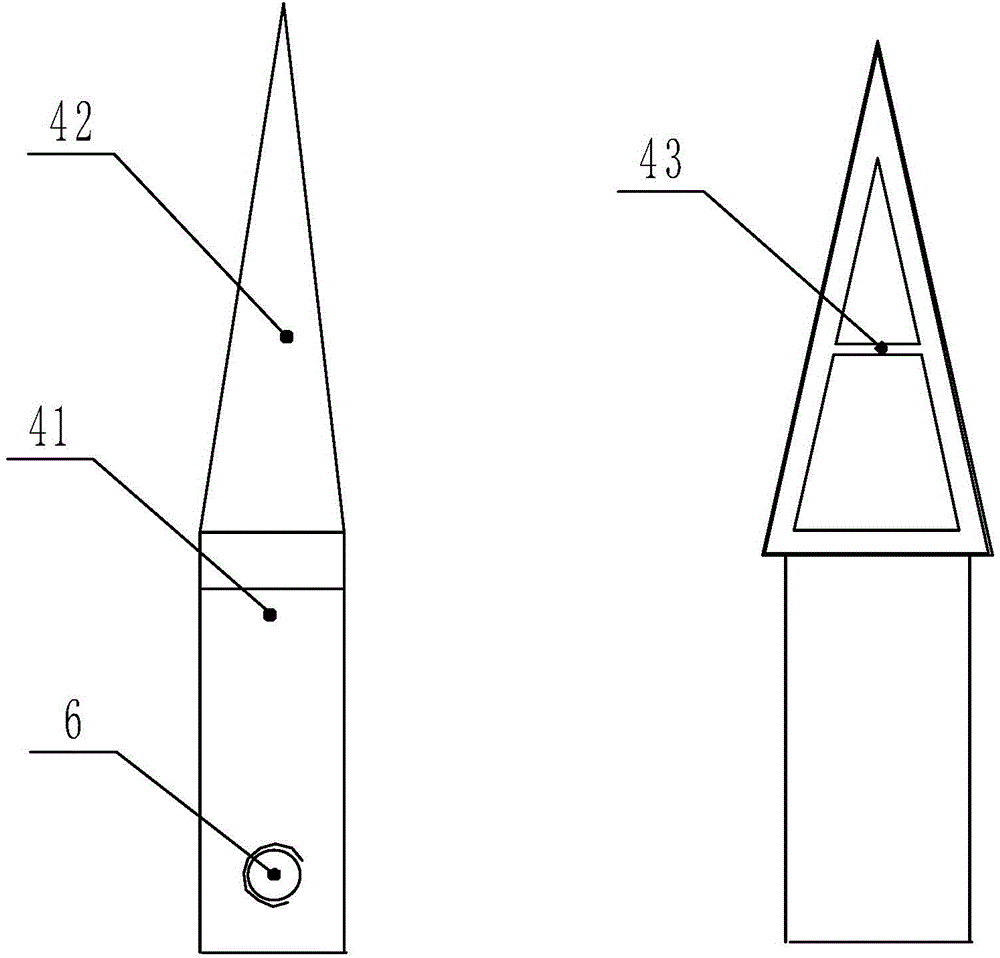

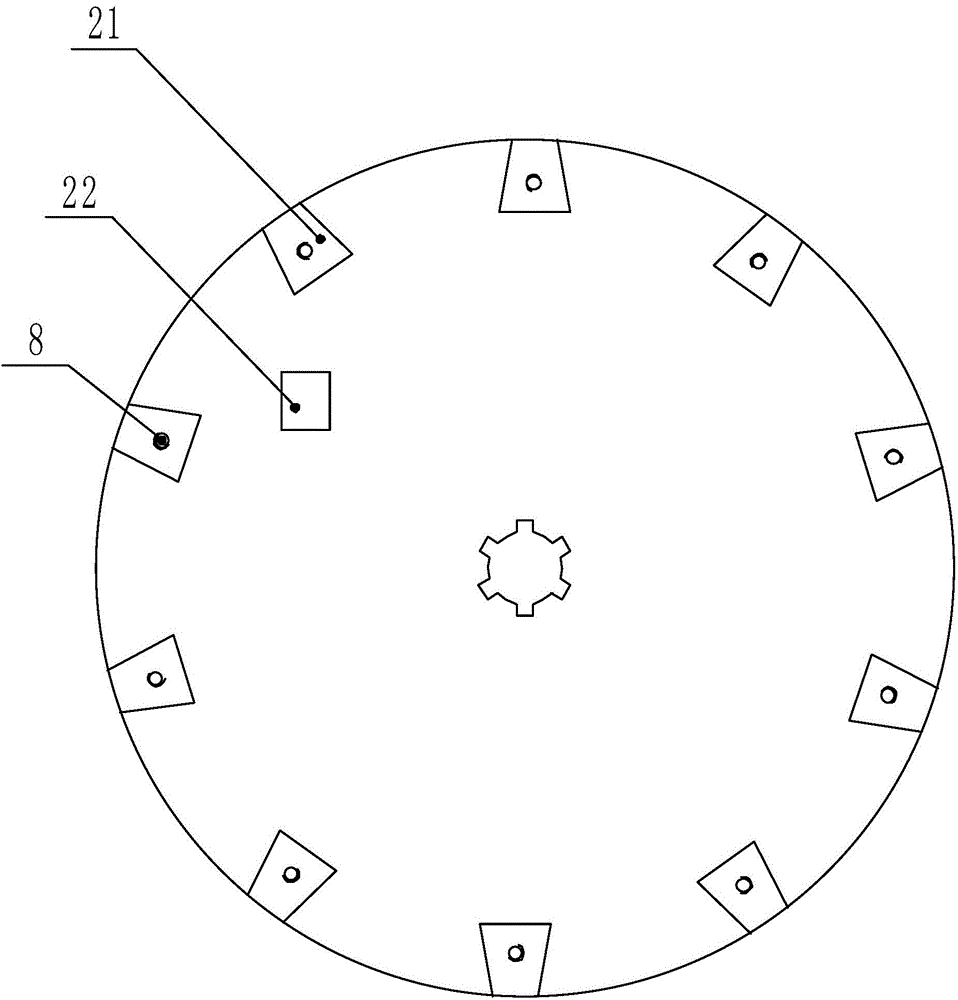

[0019] A trencher cutter head, such as figure 1 As shown, it includes a trenching knife set 1 and a knife seat 2; the trenching knife set 1 includes a cutting knife 3, a throwing knife 4 and a fixing seat 5, and the cutting knife 3 includes a cutting handle 31 and a cutting head 32. The soil cutter 4 comprises a soil-throwing knife handle 41 and a soil-throwing knife head 42; the cutting knife handle 31 and the soil-throwing knife handle 41 are of the same plate structure, and the cutting knife head 32 is a crotch shape, such as figure 2 As shown, the soil-throwing cutter head 42 is an inverted triangle with a hole in the middle, and a cross bar 43 is provided on the inside; the cutting handle 31 and the soil-throwing knife handle 41 are inserted in the fixing seat 5 and are connected with the fixing seat 5 through bolts. Installed on the knife seat 2; the knife seat 2 is disc-shaped.

[0020] The cutting knives 3 and the soil throwing knives 4 are equidistantly and alternat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com