Foundation pit supporting technique for replacing temporary enclosing purlin by using plate belt of permanent structure

A technology for permanent structure and foundation pit support, which is applied in basic structure engineering, excavation, construction, etc., can solve the problem of not being able to have both the stiffness of the enclosure and the construction speed, and avoid the difficulty of construction and the rigidity of the enclosure structure. , the effect of unearthed fast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

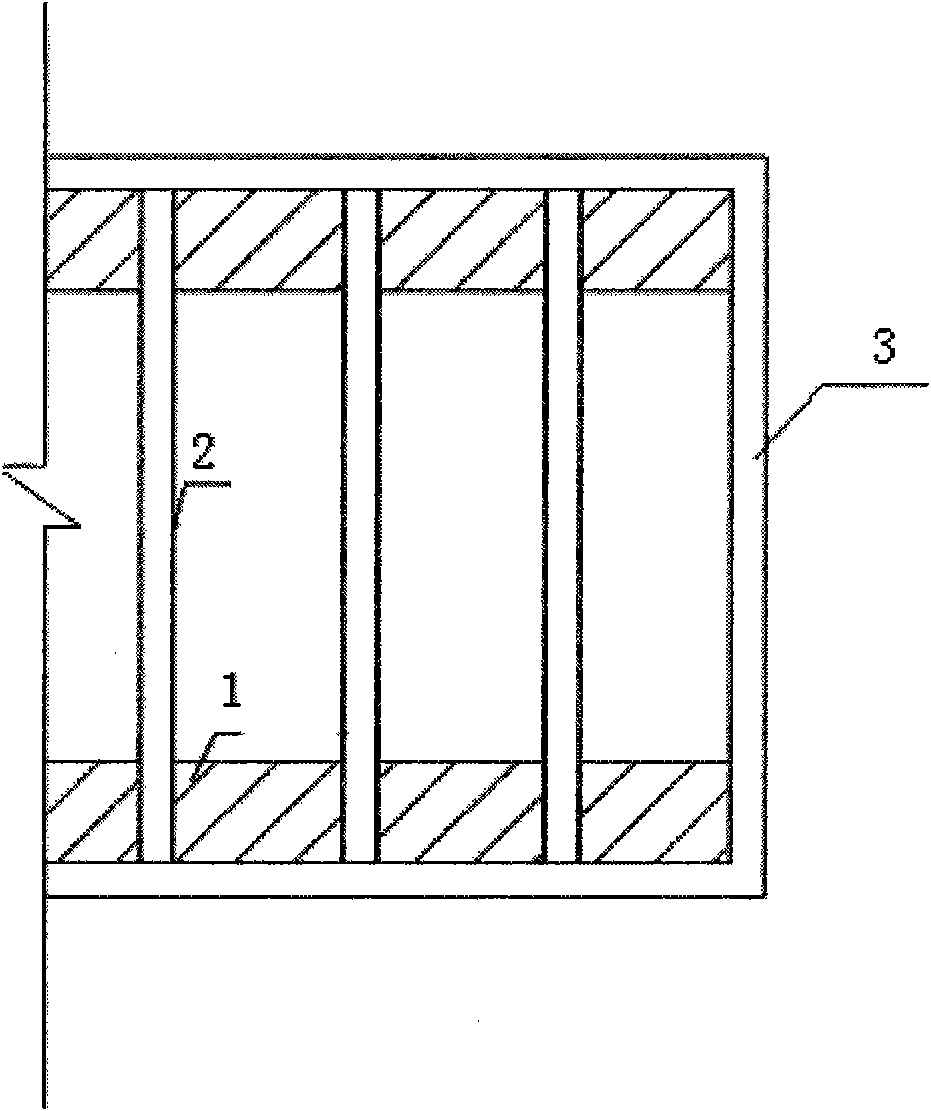

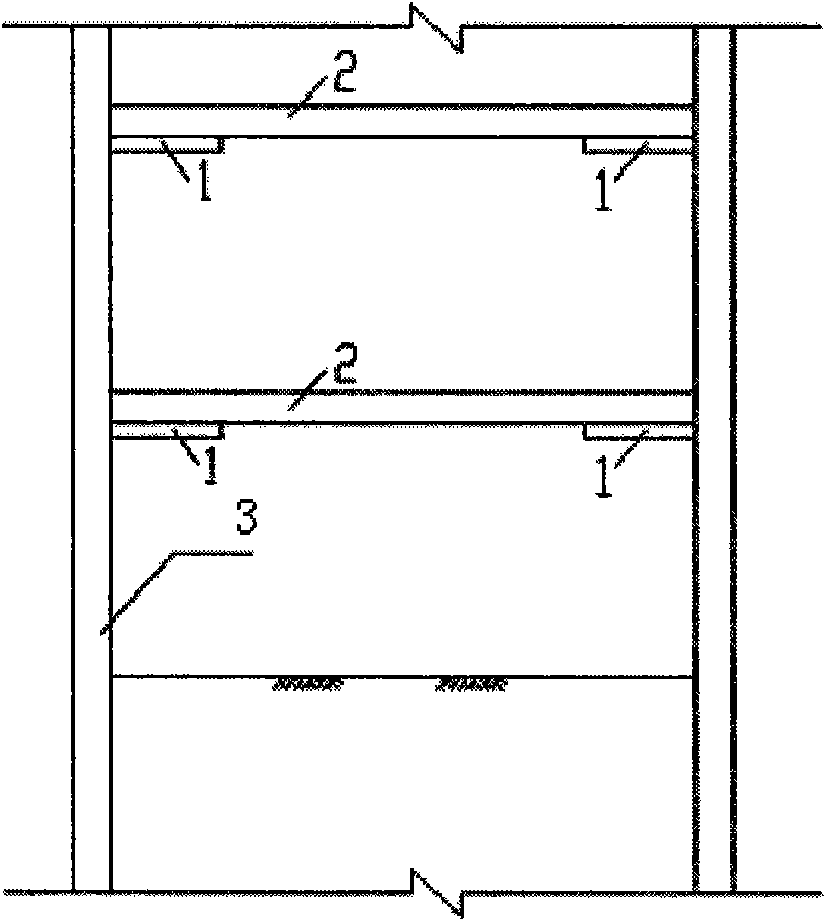

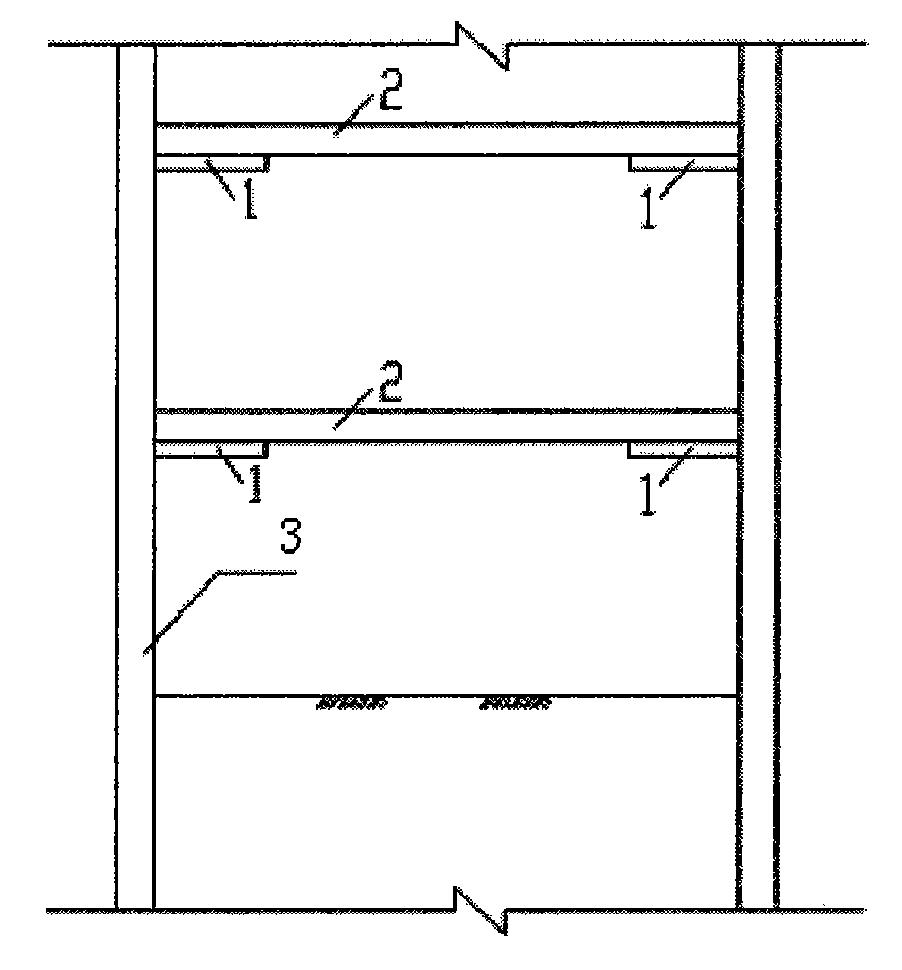

[0013] Such as figure 1 and figure 2 As shown, a foundation pit support technology in which permanent structural slabs replace temporary purlins is characterized in that: in the excavation stage of the foundation pit, the inverted slab 1 and concrete support 2 belonging to the permanent structure are used as purlins, and the foundation An enclosure structure 3 is arranged around the pit, and an upside-down slab 1 is arranged on both sides of the enclosure structure 3, and a concrete support 2 is arranged between the upside-down slabs 1 on both sides, and the two ends of the concrete support 2 are respectively connected to Envelope 3 connections. The concrete support 2 is located above the upside-down slab 1, and the bottom elevation is the same as the top elevation of the upside-down slab.

[0014] For example, a rail transit station project in Shan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com