Machine head for cutting and processing irregular steel bar

A special-shaped and chipping technology, which is applied in the field of special-shaped rod processing equipment, can solve the problems of crystal phase structure damage, low production efficiency, and affect the quality of rods, and achieve the effects of reducing costs, improving production efficiency, and saving production and processing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following descriptions are only preferred embodiments embodying the principles of the present invention, and do not therefore limit the protection scope of the present invention

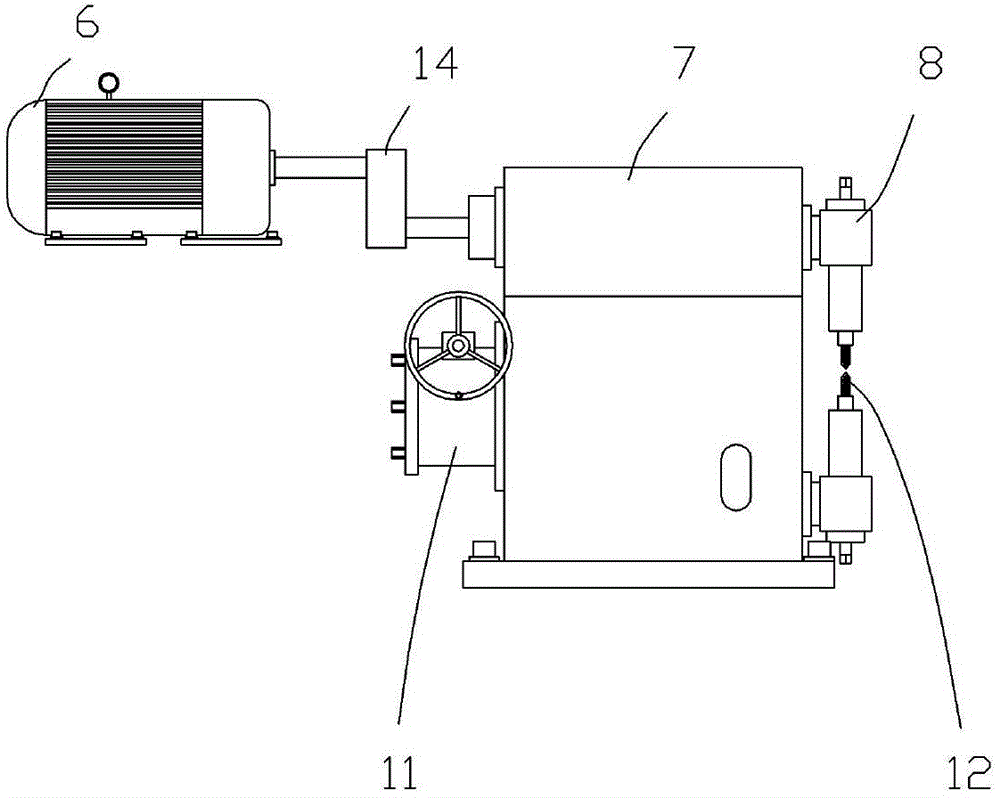

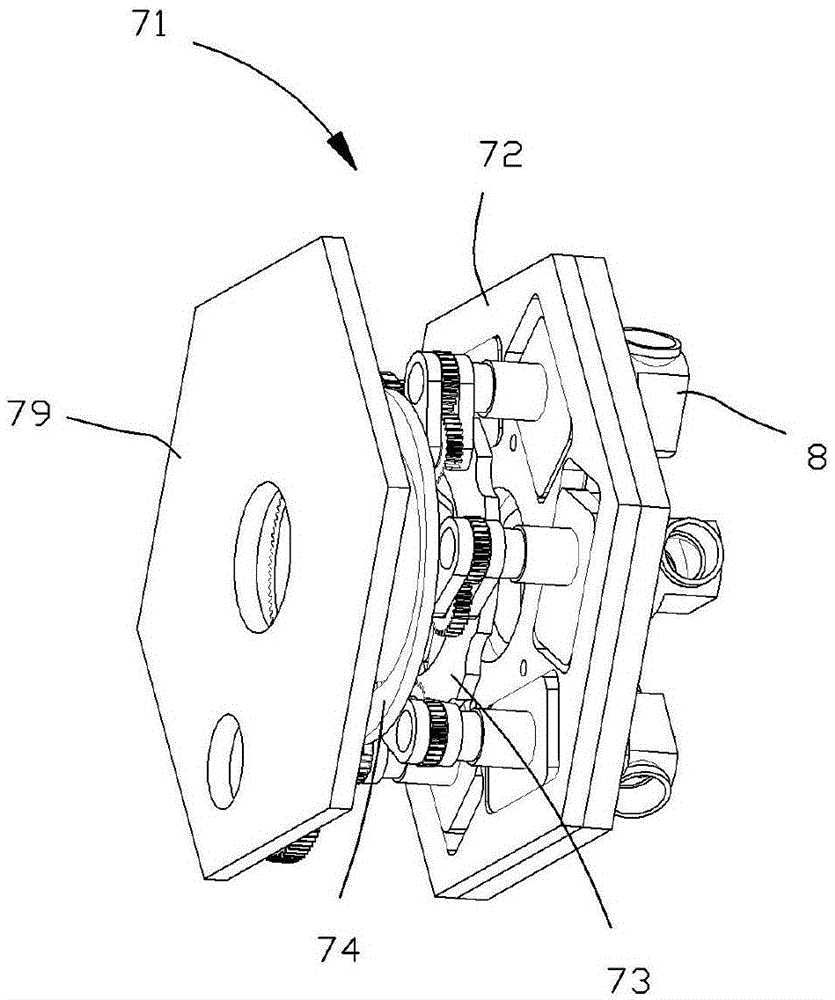

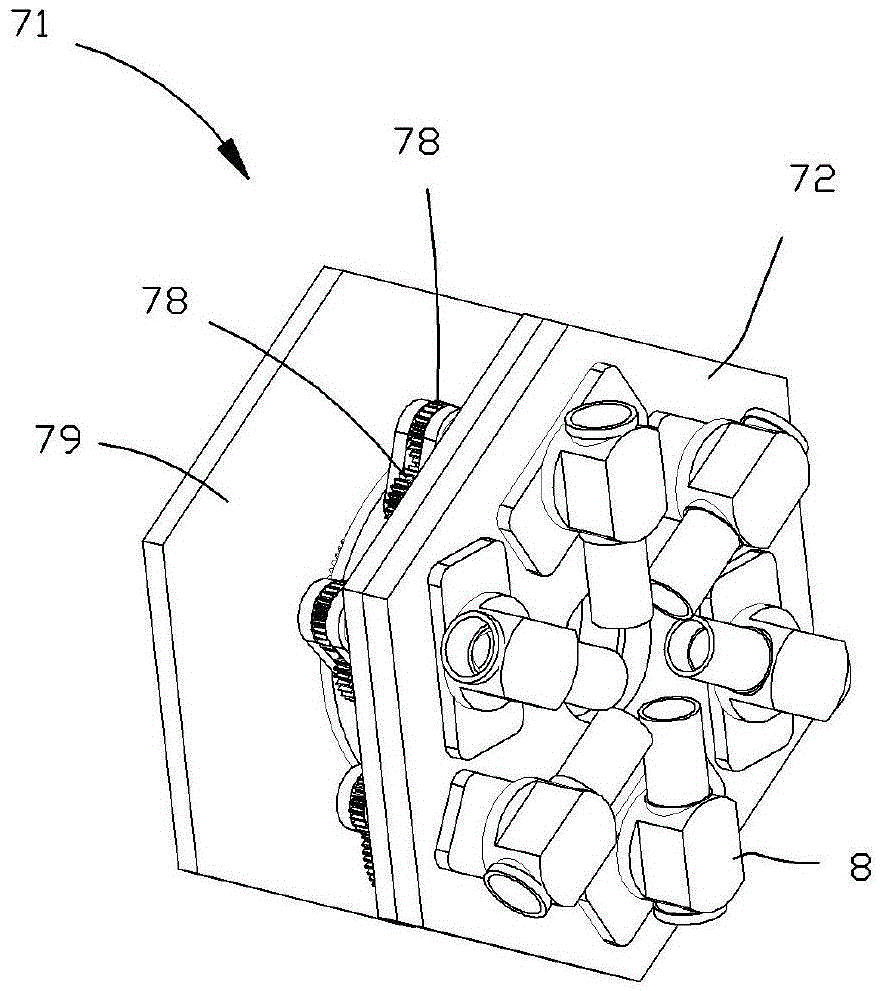

[0033] Such as Figures 1 to 15 Shown is an embodiment of a special-shaped rod chip processing machine head of the present invention, which includes a transmission box 7, a transmission mechanism 71 is arranged in the transmission box 7, and the number of the chip surface of the special-shaped rod is arranged on the transmission box 7. Equal tool mounts 8, a chipping tool 12 that can rotate along the central axis is installed in each tool mounting seat 8, and the chipping tool 12 is distributed in a circular array, and the tip of the chipping tool 12 faces inward, and the chipping tool The rotation center of 12 has an included angle with the center point of the circular array of chip cutters 12 , and the chip cutters 12 are driven to rotate by the transmission mechanism 71 .

[0034] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com