Thermal forming mechanism of plastic product box

A molding mechanism and box heating technology, applied in the field of plastic product clamping molding mechanism, can solve the problems of defective products, product deformation, cumbersome and other problems, and achieve the effect of highlighting substantive characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

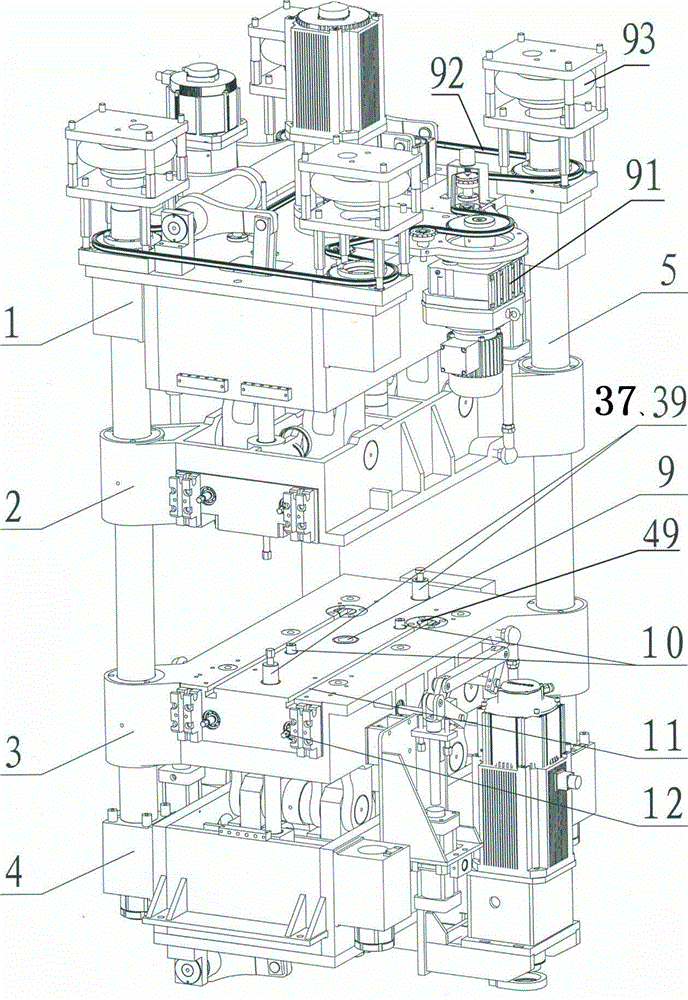

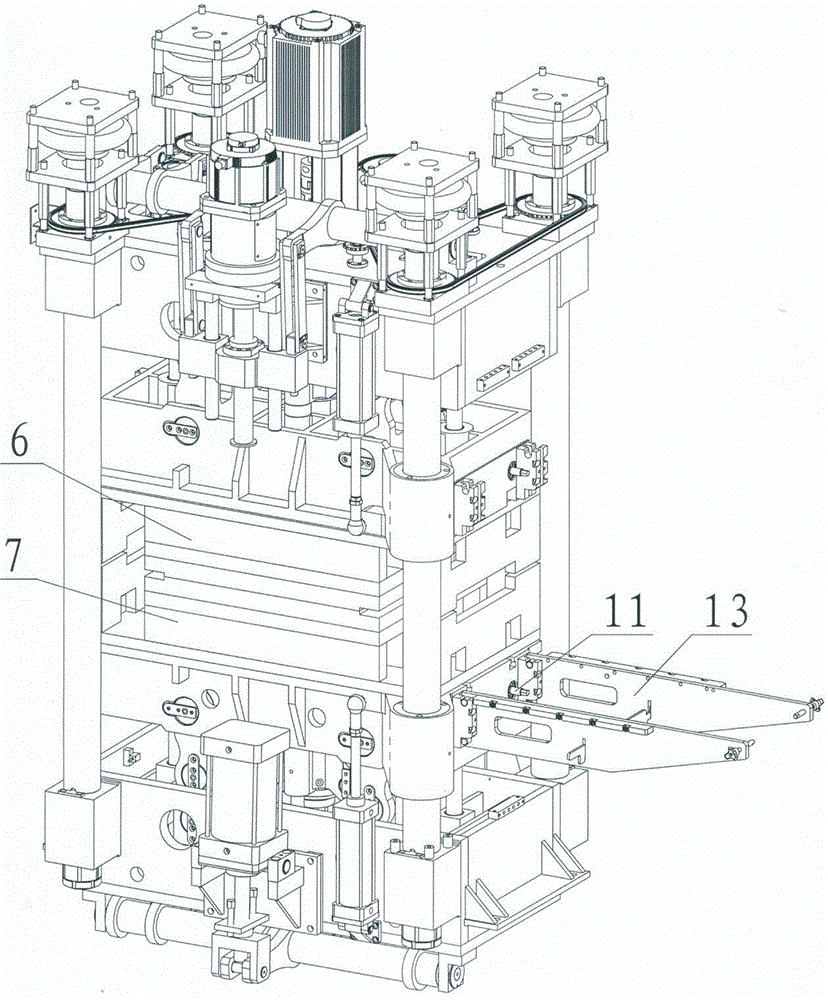

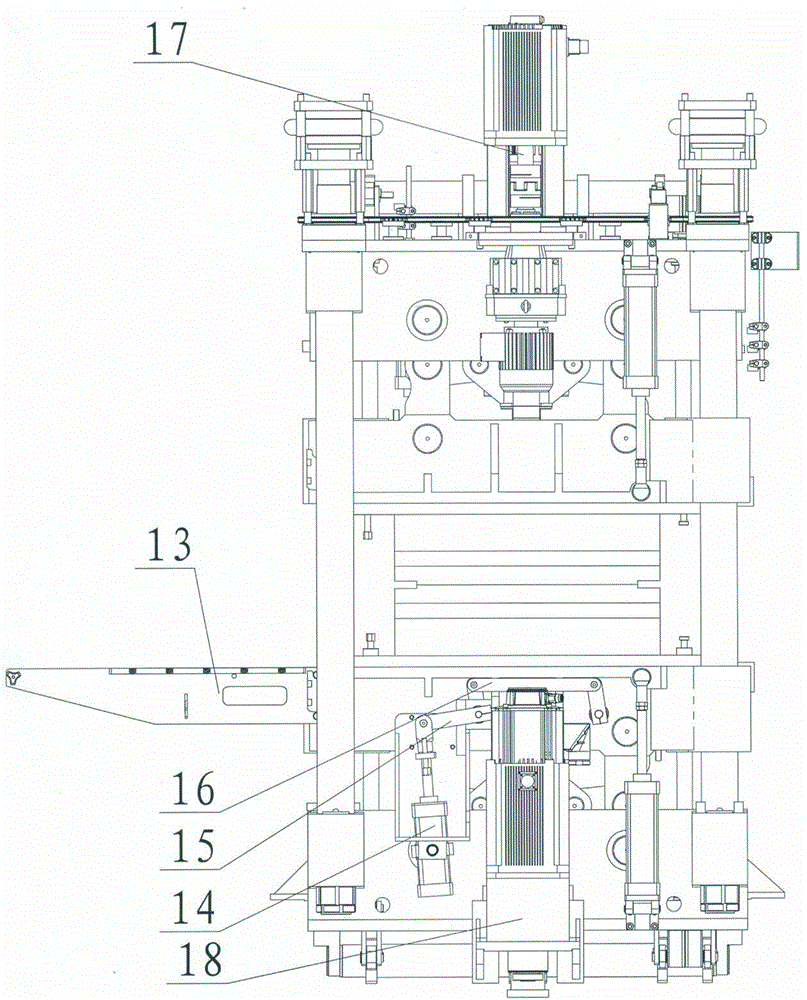

[0025] Referring to the accompanying drawings, the plastic product box thermoforming mechanism in this embodiment includes a lower mold base 4, a column 5 is arranged on the lower mold base, and an upper mold base 1, an upper mold platform 2, and a lower mold platform are set on the column 5. 3. Referring to the accompanying drawings, the upper mold base 1, the upper mold base 2, the lower mold base 3, and the lower mold base 4 are arranged from top to bottom.

[0026] The upper mold 6 is set on the upper mold platform 2, the lower mold 7 is arranged on the lower mold platform 3, and the upper and lower mold platforms 2, 3 are respectively lifted up and down by power source transmission, and the upper and lower mold platforms When 2 and 3 are close together, the upper and lower molds are closed, and when the upper and lower mold tables 2 and 3 are separated, the upper and lower molds are opened.

[0027] The upper mold base 1 and the lower mold base 4 can be used to set variou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com