Door hanging mechanism for recycling electric vehicles

A suspension mechanism and electric vehicle technology, which is applied in the direction of vehicle scrap recycling, motor vehicles, recycling technology, etc., can solve the problems of large manpower consumption, backward equipment, and low technical level, so as to reduce manpower consumption, improve efficiency, and facilitate recycling The effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

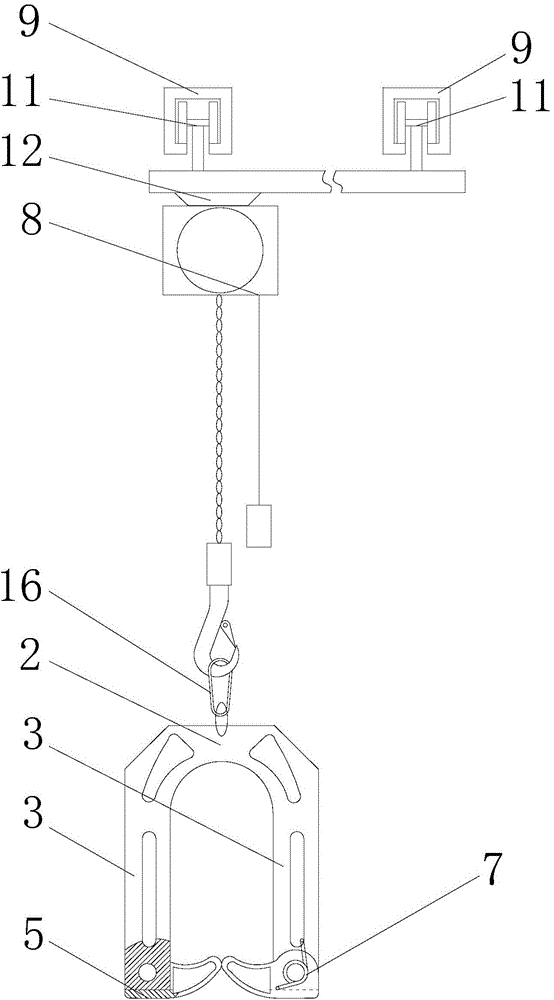

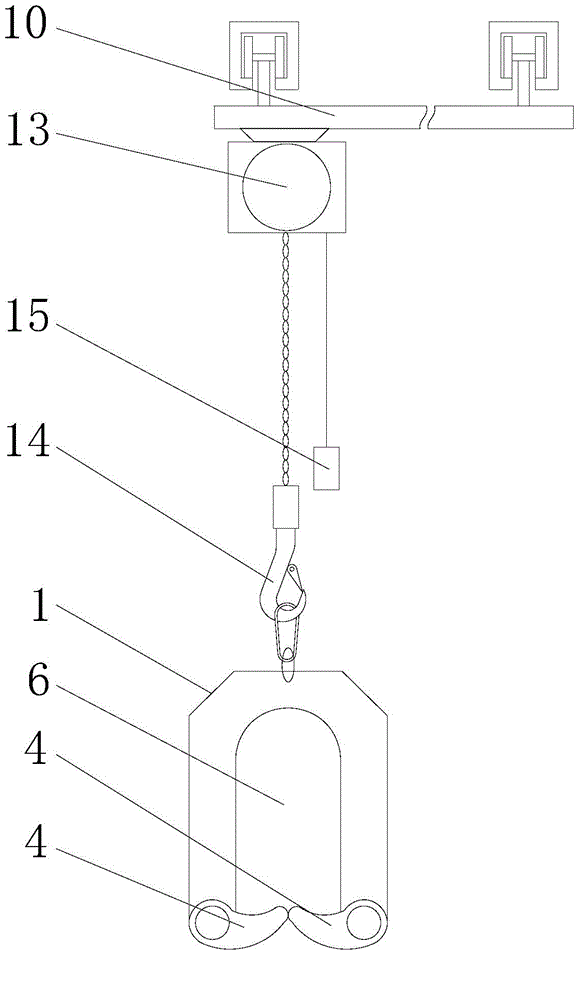

[0024] A door suspension mechanism for recycling electric vehicles, comprising a door hook 1, the door hook 1 has a hanging part 2 and claw connecting parts 3 respectively arranged on both sides of the hanging part 2 and protruding downward A movable claw 4 is arranged on the connecting parts 3 of the two claws, the movable claw 4 is hinged on the connecting part 3 of the claws, and the movable claw 4 has a Rotate the lower limit blocking piece 5 of the lower limit around the hinge, the hanging part 2, the two claw connection parts 3 and the movable claw 4 are surrounded by a hanging area 6, when the movable claw 4 is in the lower limit, The movable claw 4 closes the hanging area 6, and when the movable claw 4 rotates in the hanging area 6, the hanging area 6 is opened.

[0025] In order to better limit the rotation range of the movable claw 4, the lower limit of the movable claw 4 can be accurately defined. Preferably, the lower limit blocking piece 5 is arranged at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com