High aluminum ore blast furnace smelting method

A technology of blast furnace smelting and high alumina ore, which is applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as high viscosity of high alumina slag, poor fluidity of slag and iron, and poor air permeability of blast furnaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0085] Yilai Steel 1-6#1000m 3 A blast furnace is taken as an example to further illustrate the specific implementation of the present invention.

[0086] 1. Ingredients:

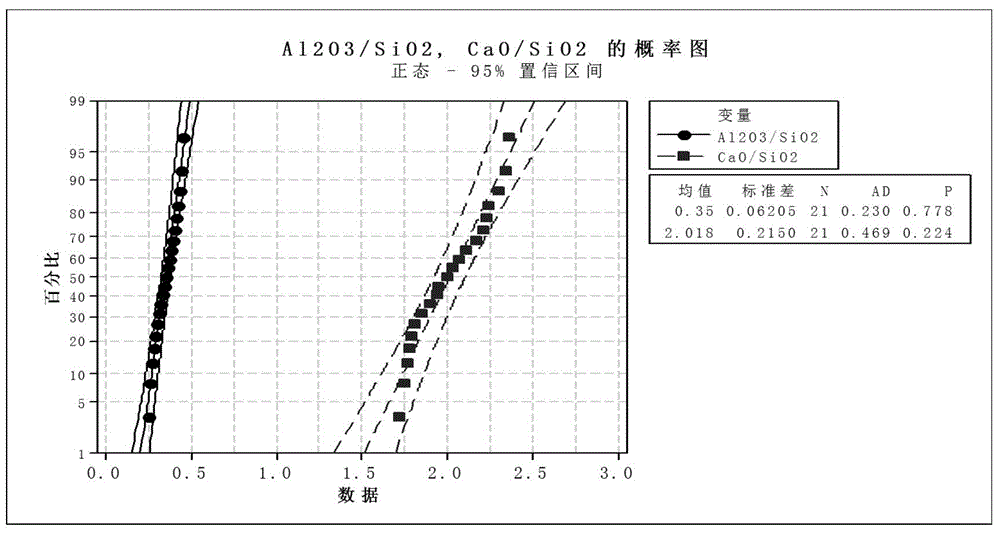

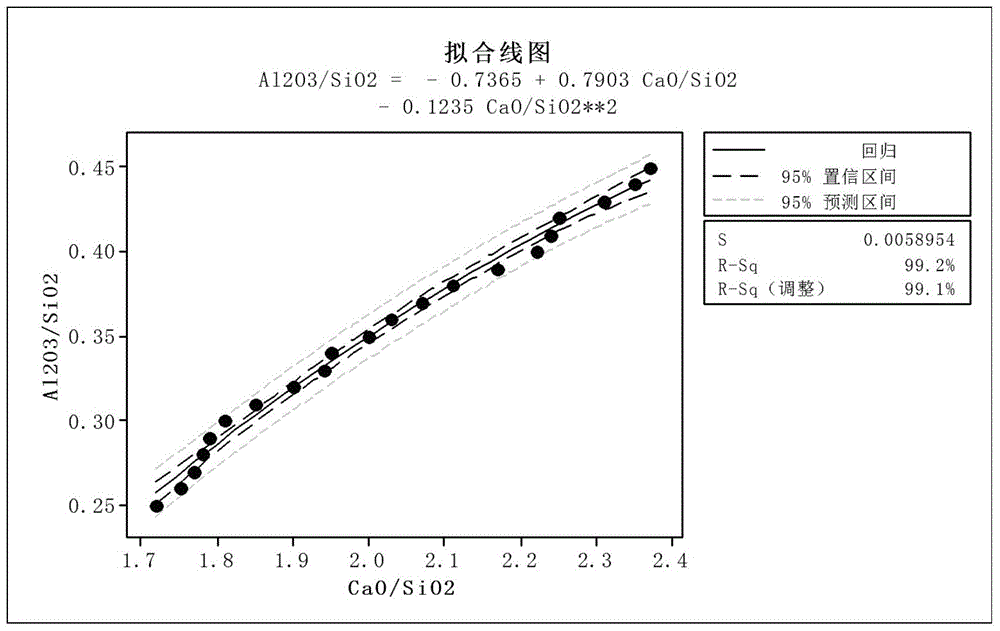

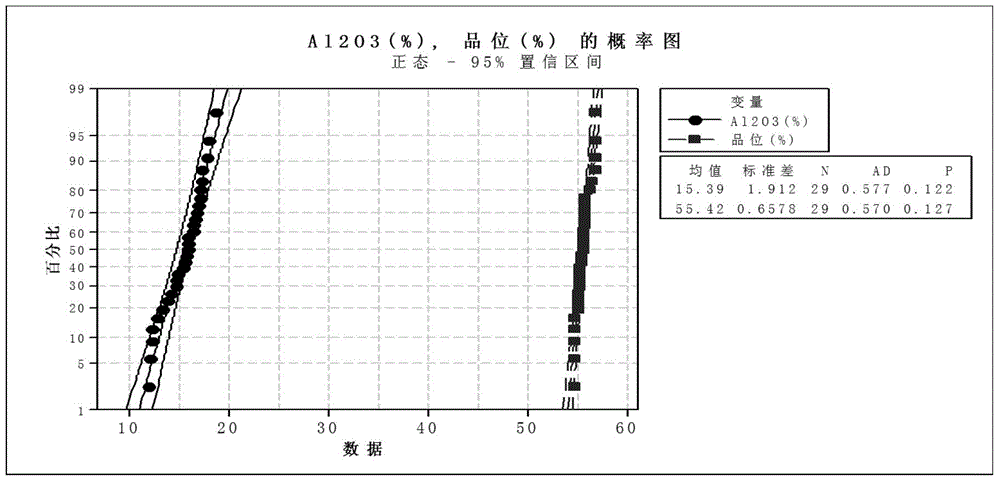

[0087] In the interface of "mineral blending", take "Al, Si, Ca" as the basic parameters, collect basic parameters, do quadratic fitting regression analysis, and then determine the control threshold of "mineral blending" from a macro perspective. The specific operation steps are as follows:

[0088] (1) Acquisition parameters are shown in Table 1:

[0089] Table 1 Mineral blending collection parameters

[0090] Al 2 o 3 / SiO 2

CaO / SiO 2

0.25

1.72

[0091] 0.26

1.75

0.27

1.77

0.28

1.78

0.29

1.79

0.3

1.81

0.31

1.85

0.32

1.9

0.33

1.94

0.34

1.95

0.35

2

0.36

2.03

0.37

2.07

0.38

2.11

0.39

2.17

0.4

2.22

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com