Anode phosphorus copper with variable area and application method thereof

A phosphor copper and anode technology, applied in the direction of the electrode, can solve the problem of reducing the current anode area and achieve the effect of changing and realizing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

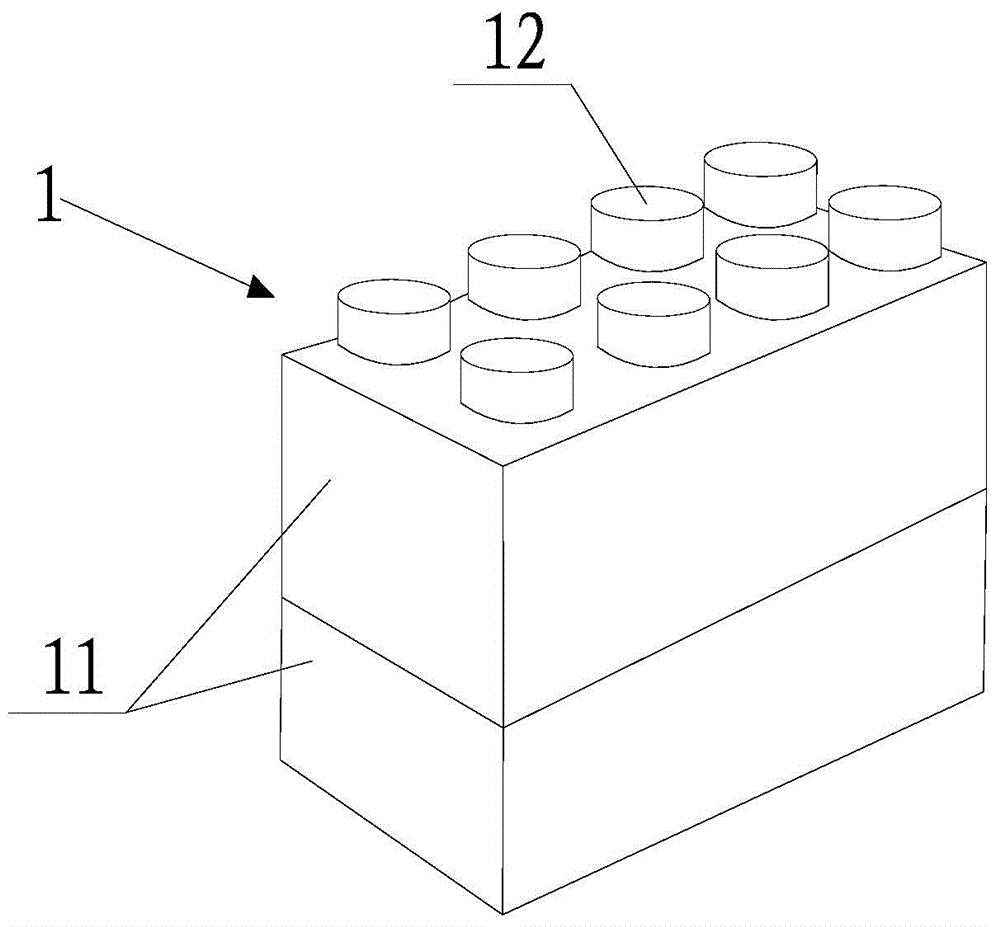

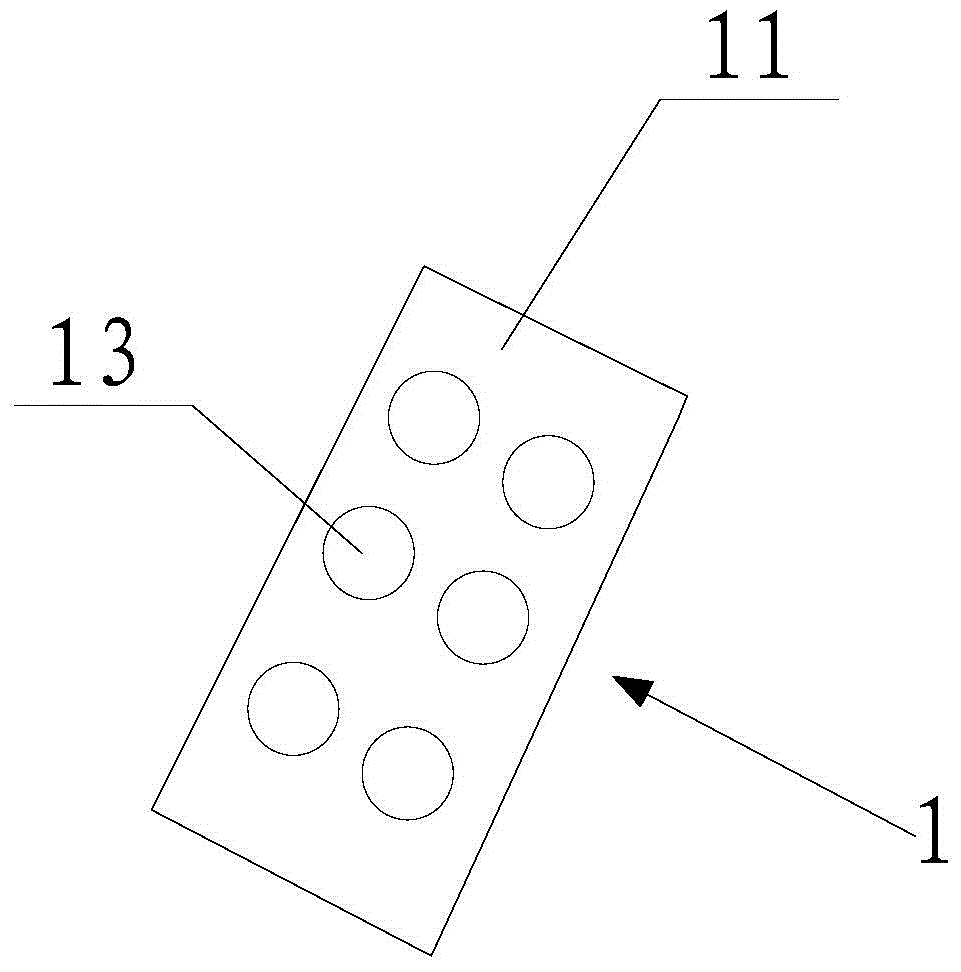

[0016] like figure 1 The variable-area anode phosphor copper shown is constructed from a plurality of phosphor copper blocks 1 , and its specific shape has no fixed pattern, and can be constructed and combined according to the actual shape of the phosphor copper blocks 1 .

[0017] The phosphor bronze block 1 includes a phosphor bronze block body 11 , protrusions 12 and concave holes 13 . Wherein, there are several protrusions 12, which are evenly distributed on any surface of the phosphor bronze block body 11, and of course the same number of protrusions 12 can be respectively arranged on multiple surfaces of the phosphor bronze block body 11 as required; There are also multiple holes 13, the number of which can be consistent with the number of protrusions 12, which are also embedded on the surface of the phosphor bronze block body 11, and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com