Drilling Waste Mud Integrated Treatment System While Drilling

A technology of waste mud and treatment system, which is applied in the direction of earthwork drilling, wellbore flushing, wellbore/well parts, etc. It can solve the problems of non-reuse, impact on surrounding environment, increase environmental risk and cost pressure, etc., and achieve soil protection and groundwater resources, increase the reuse rate, and achieve the effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

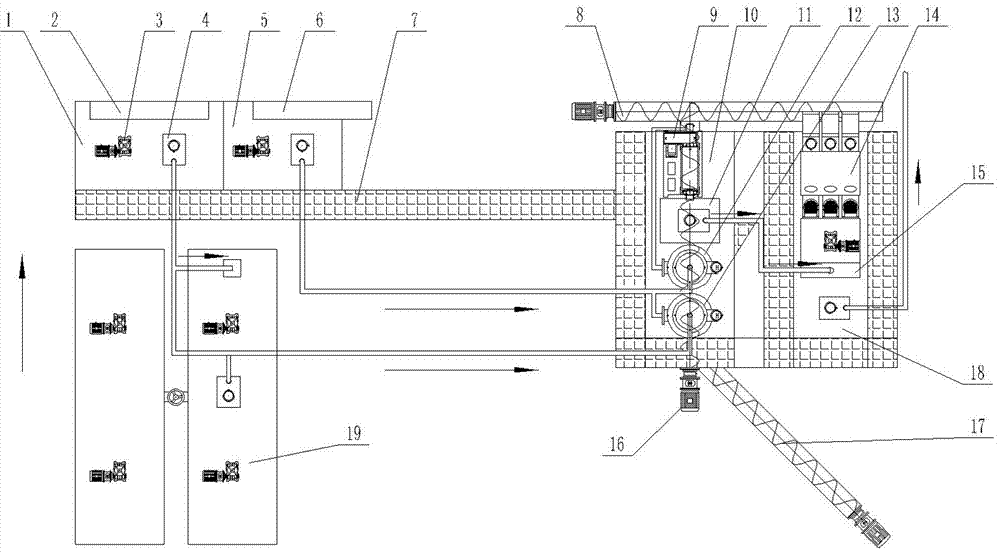

[0023] Such as figure 1 A specific embodiment shown includes a first collection tank 1, a second collection tank 5, a multi-stage solid-liquid separation module 10, a deep processing module 15 and a delivery system.

[0024] The first collection tank 1 and the second collection tank 5 are formed by dividing a silo body. An overflow baffle is arranged in the bunker body. The overflow baffle is lower than the silo wall of the bunker body, and the overflow baffle They are the first collection tank 1 and the second collection tank 5 respectively. The volume of the second collection tank 5 is smaller than that of the first collection tank 1.

[0025] The first collection tank 1 is provided with a fixed receiving tank 2 connected with the first collection tank 1; the second collection tank 5 is provided with an adjustable receiving tank 6 connected with the second collection tank 5; A horizontal guide rail is fixed on the collection tank 5, and the adjustable receiving groove 6 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com