Integrated treatment method for drilling waste mud

A technology of waste mud and treatment method, which is applied in the direction of earthwork drilling, wellbore flushing, wellbore/well components, etc., which can solve the problems of surrounding environmental impact, non-recyclable, increased environmental risk and cost pressure, etc., to achieve improved return utilization rate, protection of soil and groundwater resources, and the effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] The mud produced by the inherent desander, desilter and vibrating screen of the well team is sequentially separated from solid and liquid through the cuttings deslimer, sand removal machine and water treatment regeneration machine, so that the liquid phase is sequentially passed through the cuttings deslurry The solid phase produced by the cuttings deslimer, sand removal machine, water treatment regeneration machine and the centrifuge inherent in the well team is transported through the screw conveyor To the transport vehicle, the curing agent is added to the solid phase in the screw conveyor during the conveying process of the screw conveyor.

[0028] The debris deslimer uses a vibrating screen, the sand removal machine uses a centrifuge, the water treatment regeneration machine is a sludge dewatering machine, and the sludge dewatering machine can use a screw stacker.

example 2

[0030] This specific example adopts the following integrated treatment equipment for drilling waste mud on the basis of the method in Example 1.

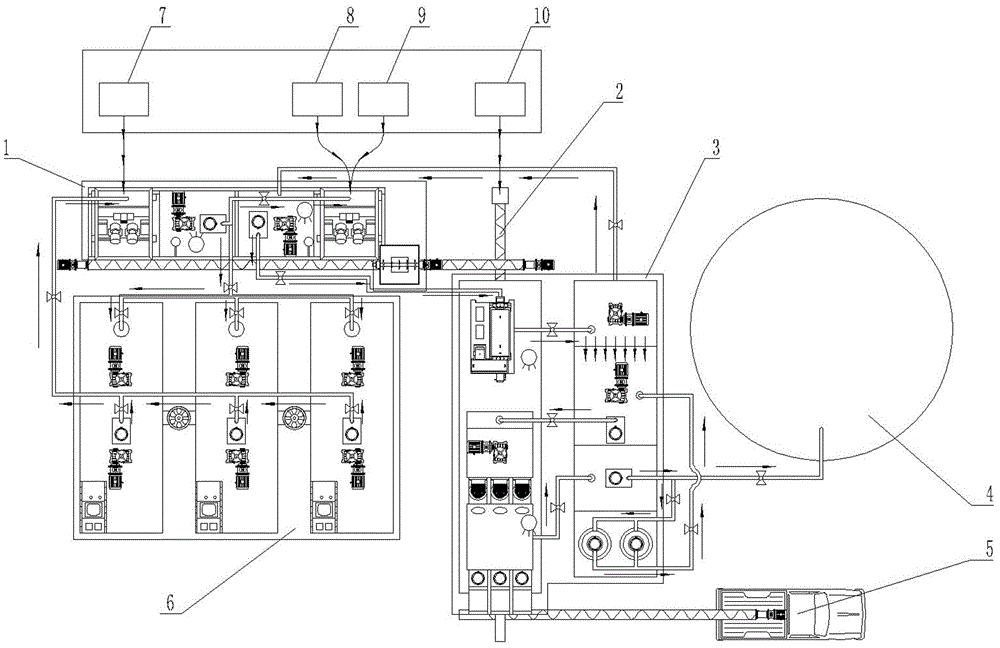

[0031] Such as figure 1 An integrated processing equipment for drilling waste mud is shown, which includes an automatic classification and collection module 1 , a solid phase conveying system 2 , a multi-stage solid-liquid separation combination module 3 and a soft water tank 4 .

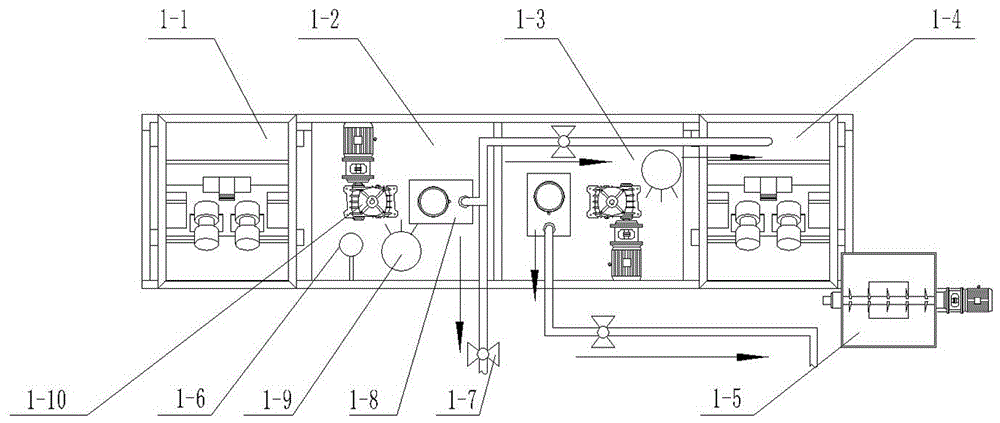

[0032] Such as figure 2As shown, the automatic classification and collection module 1 includes a first cuttings desizing machine 1-1, a first slurry storage tank 1-2, a second slurry storage tank 1-3, a second cuttings desliming machine 1-4, a solidification Agent adding machine 1-5, valve 1-7, pump 1-8, LED explosion-proof lighting 1-9 and agitator 1-10. The first slurry storage tank 1-2 and the second slurry storage tank 1-3 are formed by dividing a tank body, and an overflow partition is provided in the tank body, and the overflow partition is lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com