Intelligent steam regulation real-time control method and device

A real-time control and steam technology, applied in the direction of earthwork drilling, mining fluid, wellbore/well components, etc., can solve the problems of inability to self-diagnose and protect devices, loss of manpower, material resources, easy expansion of faults, etc., to improve detection accuracy And the effect of sensitivity, guaranteed flow and guaranteed pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

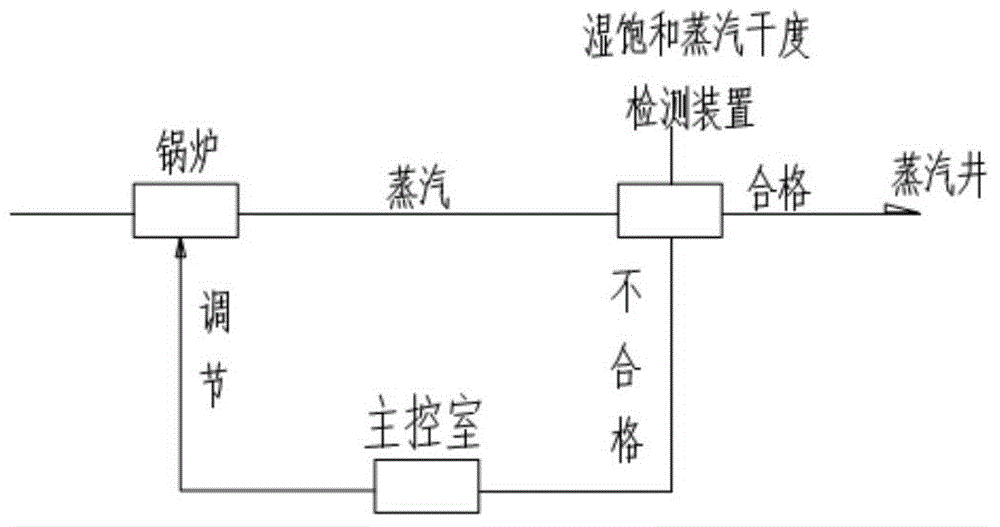

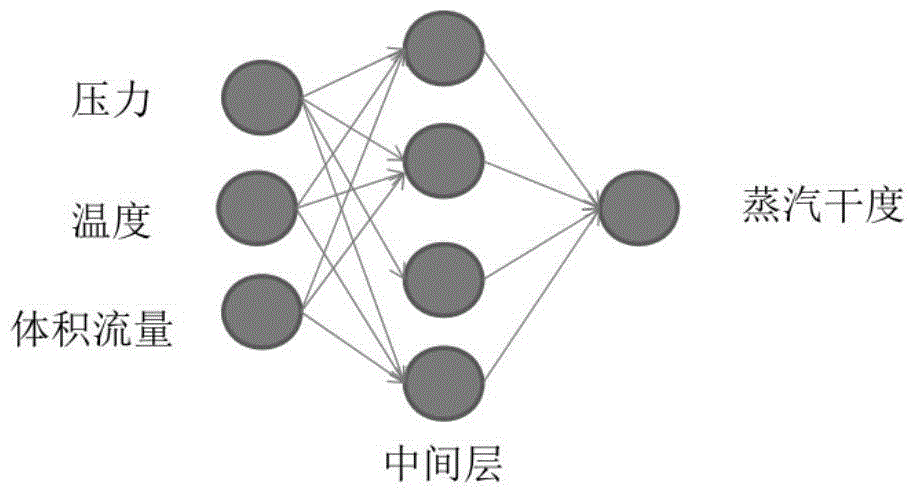

[0044] Figure 1-2 The steam dryness output of the boiler is controlled by the wet saturated steam dryness detection technology, and the actual dryness of the steam is fed back in real time, so that the main control room can adjust the level of the steam dryness in real time to ensure the efficiency of steam injection. Using Radial Basis Neural Network (RBF) technology, combining soft sensor technology with the existing dryness intelligent detection device, developing real-time online detection, feedback and alarm technology of wet saturated steam dryness to improve detection accuracy and sensitivity.

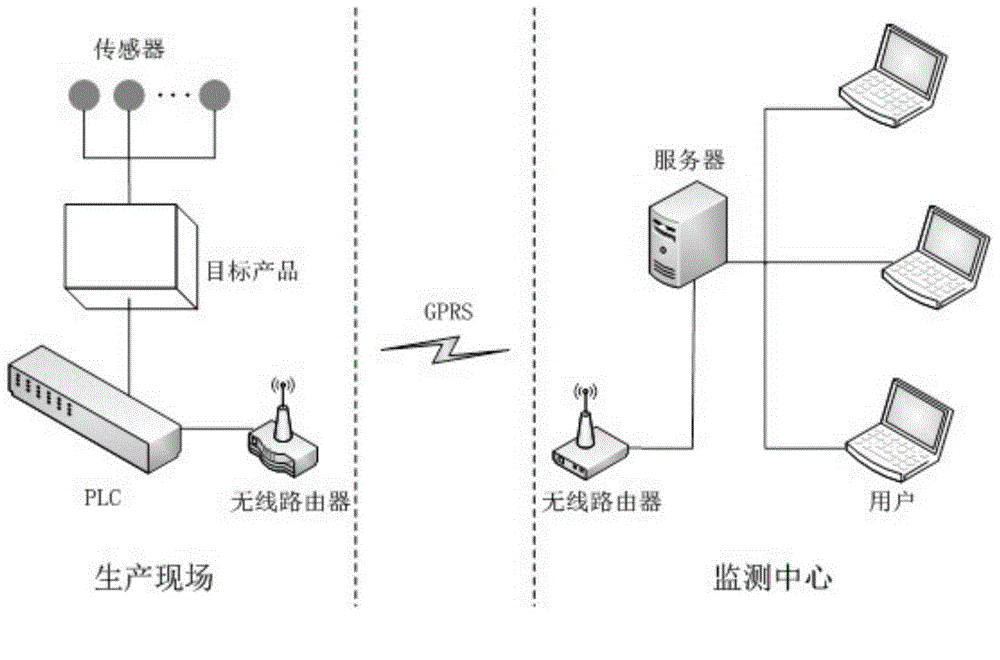

[0045] The structure diagram of online monitoring and remote operating system is as follows: image 3 As shown, the main control room and the field control of the present invention are provided.

[0046] Figure 4 Among them, when the electric thermal recovery wellhead steam valve V2 is behind the electric regulating valve V, the electric regulating valve is finally opened fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com