Well drilling comprehensive speed accelerating optimization expert system

An expert system and drilling technology, applied to the automatic control system of drilling, drilling equipment, drilling measurement, etc., can solve problems such as geographical restrictions, time-consuming and analysis process, and difficulty in proposing guiding measures to optimize drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] In order to make the technical features and effects of the present invention more obvious, the technical solutions of the present invention will be further described below in conjunction with the accompanying drawings. The present invention can also be described or implemented in other different specific examples. The equivalent transformations done within all belong to the protection category of the present invention.

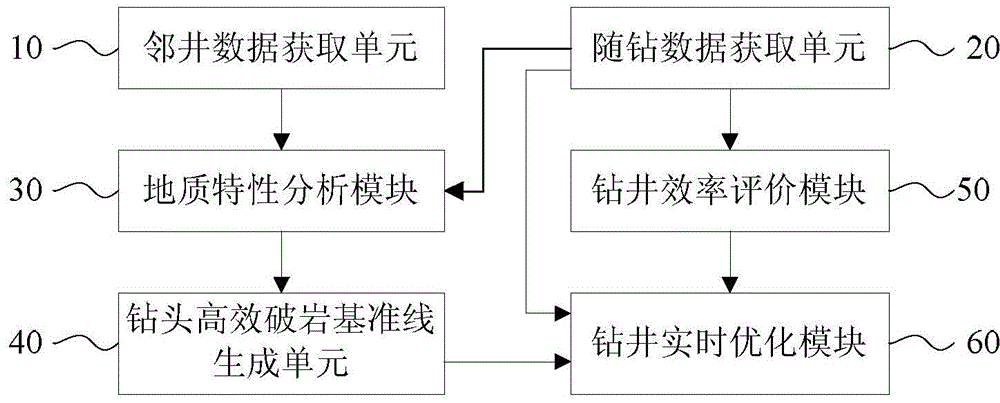

[0050] Such as figure 1 as shown, figure 1 It is a structural diagram of an expert system for comprehensive drilling speed-up optimization in an embodiment of the present invention, wherein the expert system includes: an adjacent well data acquisition unit 10, a data acquisition while drilling unit 20, a geological characteristic analysis module 30, and a drill bit efficient rock-breaking baseline generation unit 40. Drilling efficiency evaluation module 50 and drilling real-time optimization module 60. The adjacent well data acquisition unit is used ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com