Novel air return way advance support

A technology of advanced support and return airway, which is applied in the direction of mine roof support, mining equipment, earthwork drilling and mining, etc., can solve problems such as unstable standing, poor connection of support beams to the top, uneven structural force, etc. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

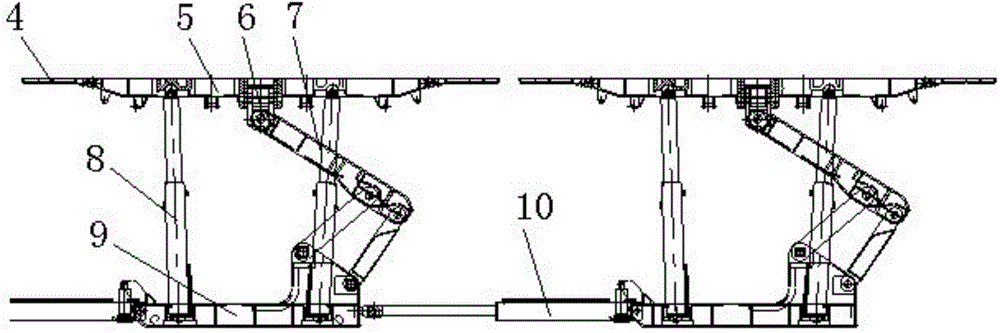

[0017] The novel air return lane advance support of the present invention, its preferred embodiment is:

[0018] It includes an integral base and an integral top beam, the middle of the integral top beam is provided with a crosshead hinge point, and columns are respectively provided between the front and rear parts of the integral top beam and the integral base, and the crosshead is hinged A shield beam is provided between the point and the rear of the integral base.

[0019] The crosshead hinge point is provided with two mutually perpendicular hinge shafts, the upper hinge shaft is arranged horizontally and is hinged with the middle part of the integral top beam, and the lower hinge shaft is arranged vertically and is hinged with the upper end of the shield beam.

[0020] The front part and the rear part of the integral top beam are symmetrically arranged around the hinge point of the crosshead.

[0021] The front end, rear end and both sides of the integral top beam are res...

specific Embodiment

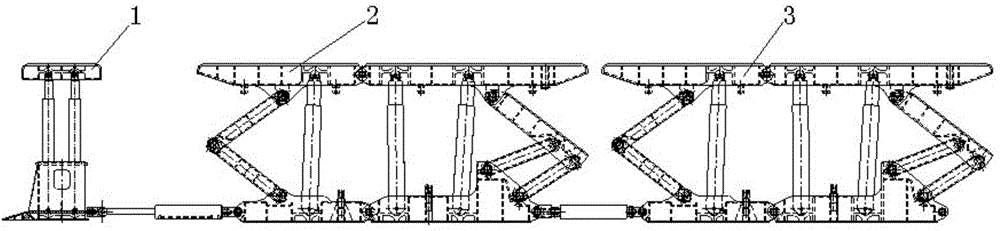

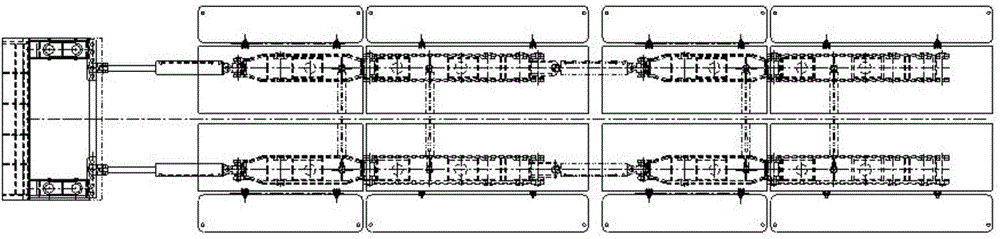

[0024] Such as image 3 , Figure 4 As shown, the new return airway advance support of the present invention adopts an integral form of the base and the top beam, the base has a large bottom contact area, and the bottom plate has a small specific pressure, which can adapt to the uneven working conditions of the roadway bottom plate. The overall roof beam plus the front, rear, left and right side wall panels can increase the area of the roof protection and protect the safety of personnel.

[0025] Such as Figure 5 , Figure 6 As shown, the overall top beam and the cover beam are hinged with a cross head, so that the support top beam can deflect left and right at a certain angle during use, which can well adapt to the uneven working conditions of the roadway roof. Each support adopts four-column form, which has good stability and strong lodging resistance.

[0026] The advance support in the return airway in the prior art is disassembled when going down the well, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com