Array substrate and its forming method

A technology of array substrates and shift registers, which is applied in digital memory information, instruments, calculations, etc., to achieve the effects of narrow frame design, reduced width, and reduced area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

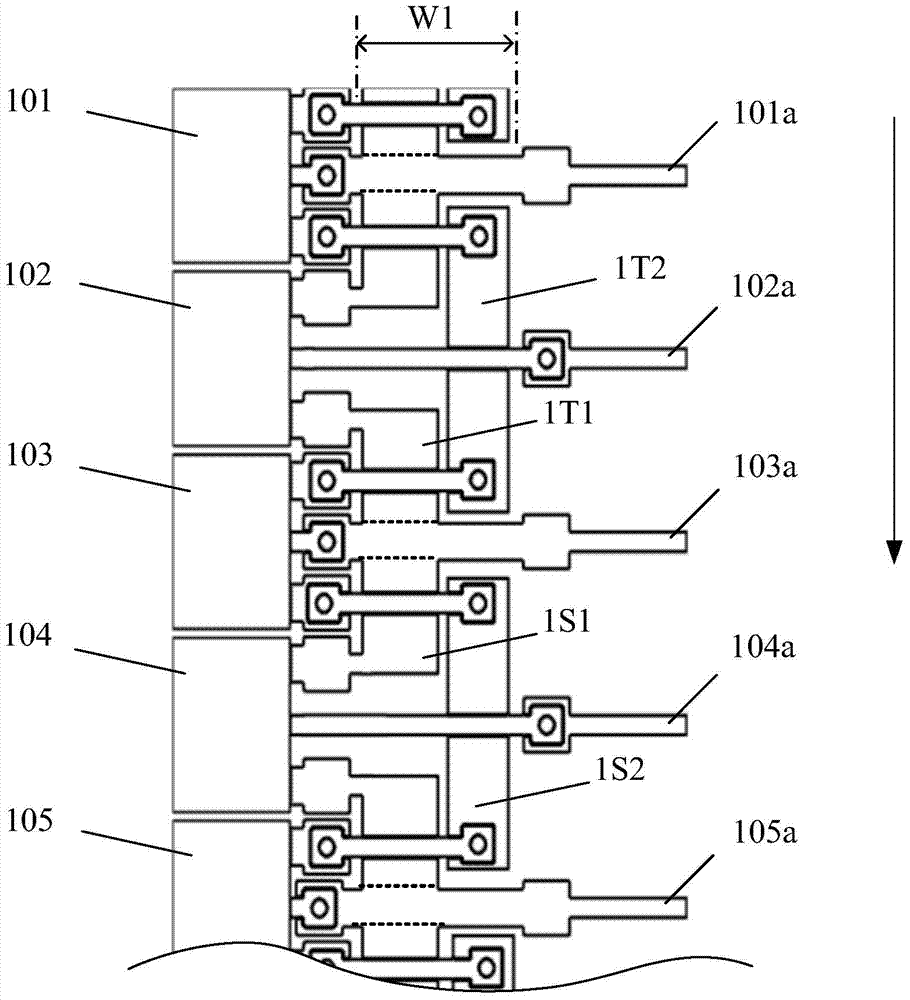

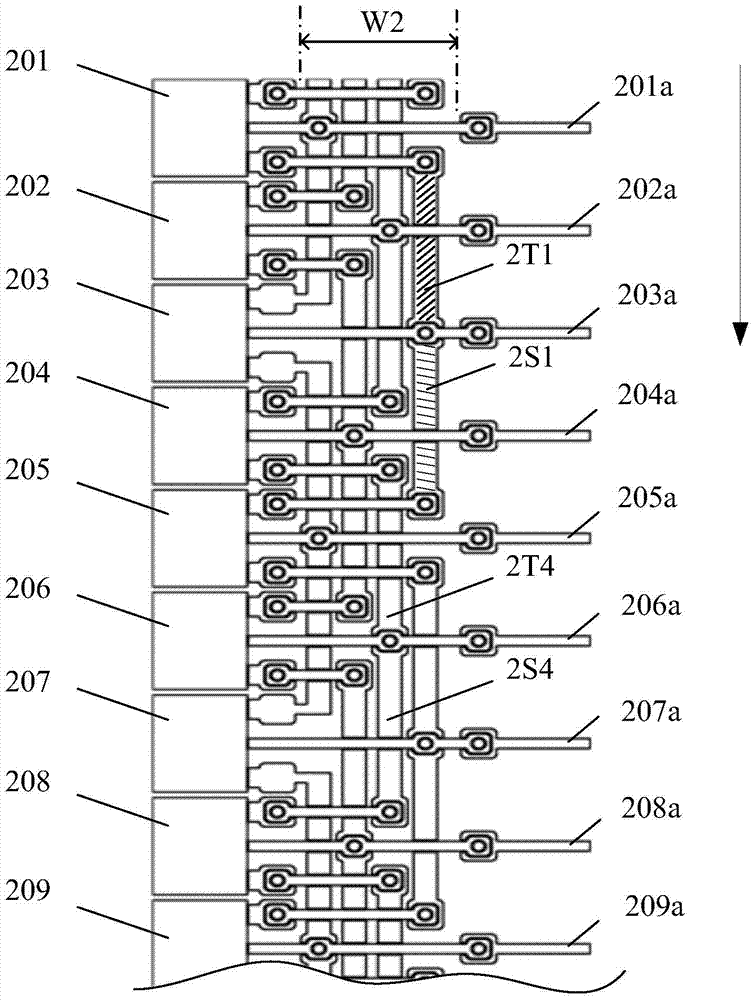

[0026] figure 1 It is a schematic structural diagram of a partial top view of an array substrate, showing a part of the non-display area of the array substrate. The non-display area has a gate drive circuit. The gate drive circuit includes a shift register circuit. The shift register circuit includes two shift register groups, namely a first shift register group and a second shift register group. Both of the shift register groups include a plurality of shift registers. figure 1 The shift register 101 to the shift register 105 are shown as representatives in , and their gate output terminals are respectively the gate output terminal 101a to the gate output terminal 105a. Wherein, an odd number of shift registers belongs to the first shift register group, that is, the shown shift register 101 , shift register 103 and shift register 105 all belong to the first shift register group. An even number of shift registers belongs to the second shift register group, that is, both t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com