Wafer alignment mark

A technology for aligning marks and wafers, applied in electrical components, electric solid-state devices, circuits, etc., can solve the problems of affecting wafer bonding accuracy, waste of resources, and reducing the effective area of the chip, and achieve a large effective area of the chip. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

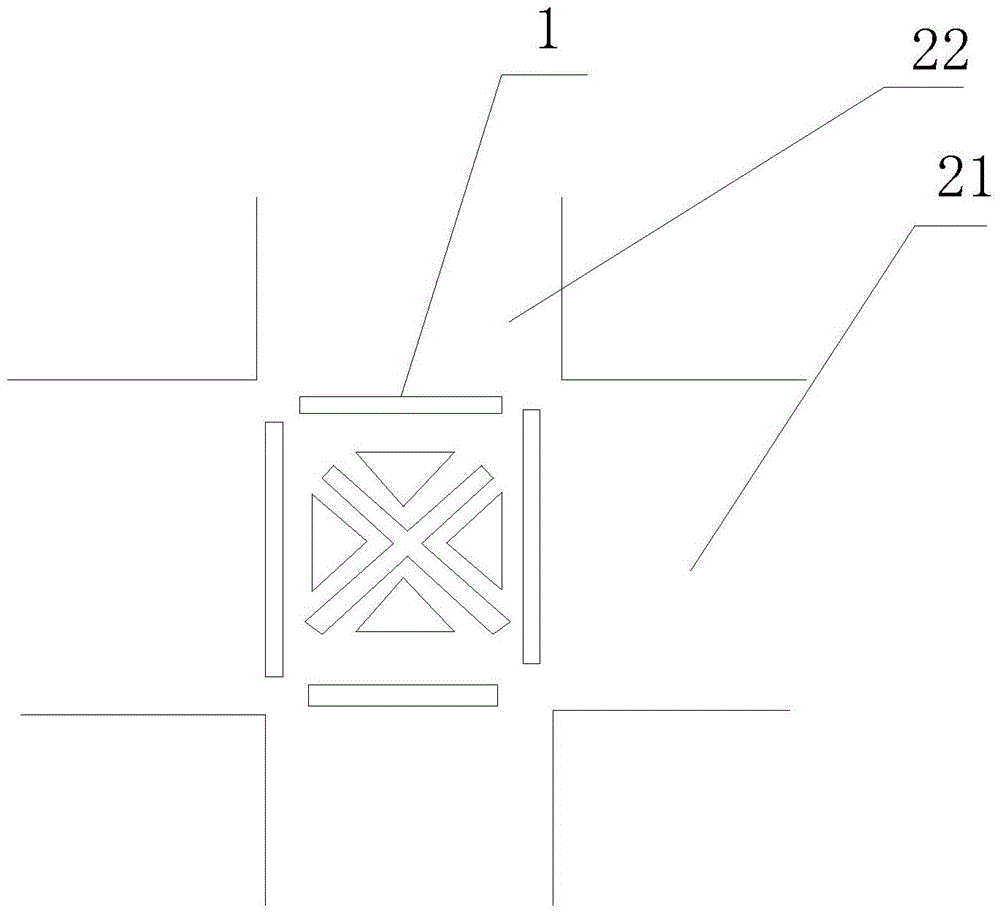

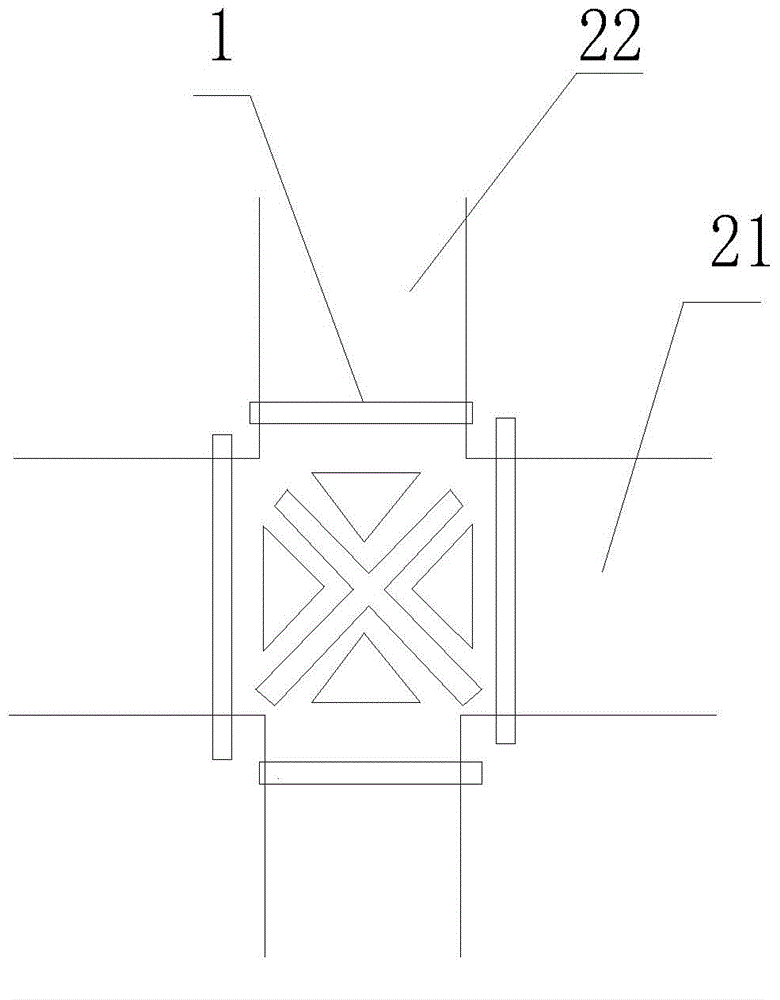

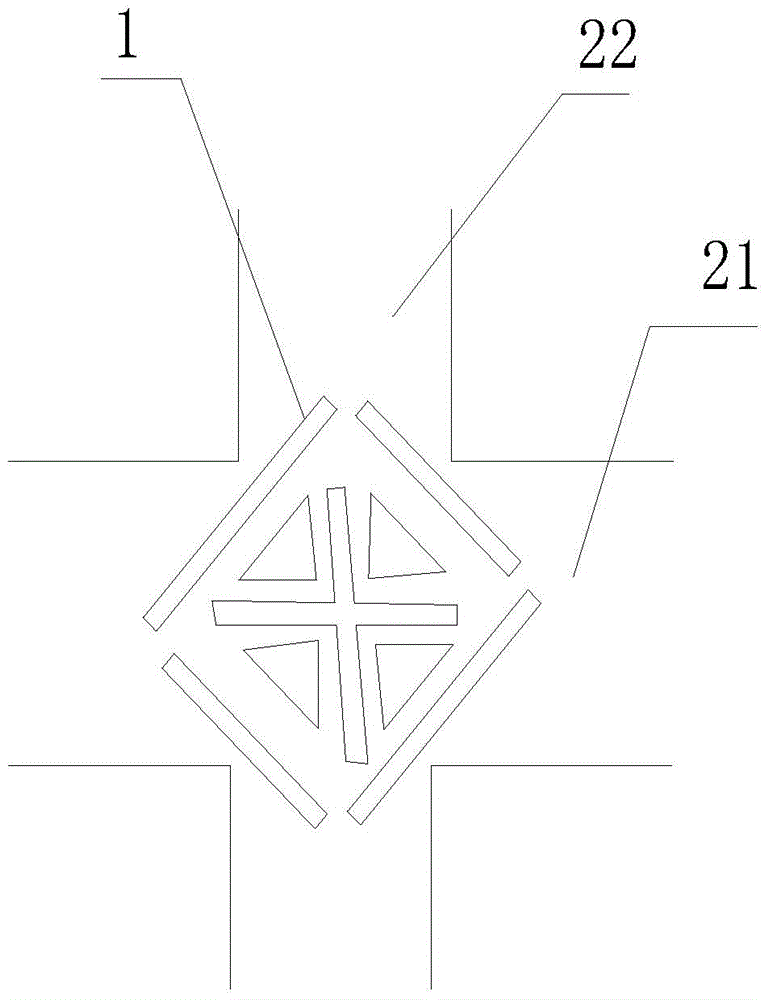

[0018] The invention discloses a wafer alignment mark. The alignment mark can be applied in the bonding process of wafers. The wafer is provided with cutting lines intersecting each other, and a tip pattern is provided on the crossing area of the cutting lines. alignment marks, and the tip pattern extends into non-intersecting areas of the dicing lanes.

[0019] In a preferred embodiment of the present invention, the above-mentioned cutting lines may include horizontal cutting lines and vertical cutting lines perpendicular to each other.

[0020] On this basis, further, the angle formed between the alignment mark and the horizontal cutting line is not 0°, preferably, the value range of the angle between the alignment mark and the horizontal cutting line is 30°-60°( For example 30°, 45°, 50° o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com