Versatile Overcurrent Clamp for Vertical Mounting

A vertical installation and multi-functional technology, applied in the field of tools, can solve the problems that will affect other procedures of the operation, the insulation rod is not connected, the insulation rod cannot be disassembled, etc., to achieve the scope of improving operability, avoiding dangerous factors, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

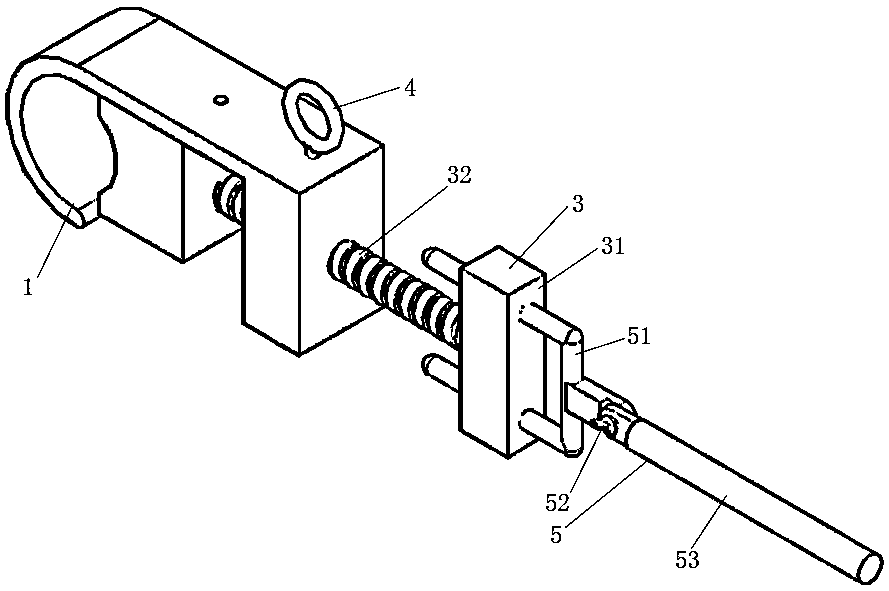

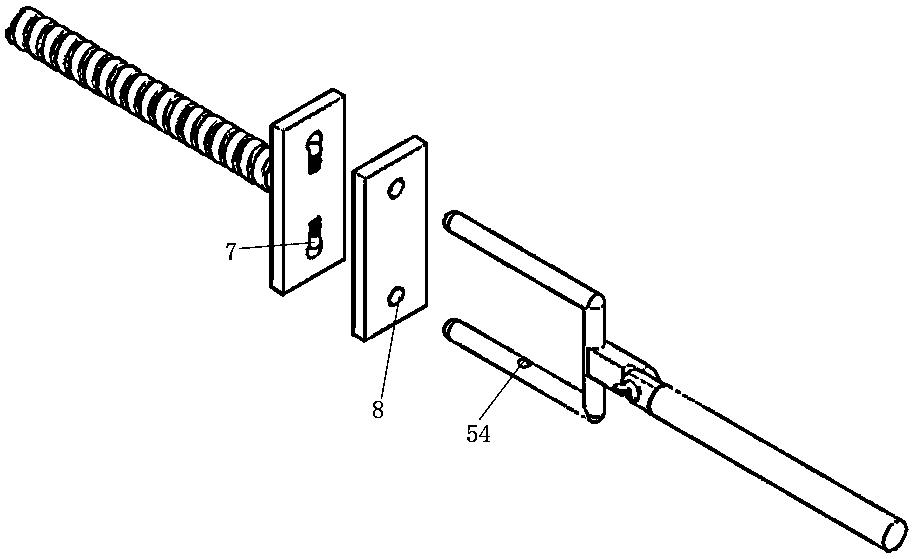

[0019] like figure 1 , 3 As shown, the multifunctional overcurrent fixture that can be installed vertically includes a wire clamping groove 1, a T-shaped installation head 3 and an insulating U-shaped installation rod 5. The T-shaped installation head 3 includes a locking screw 32 and an installation plate 31, the locking screw 32 is vertically installed in the middle of the mounting plate 31, and there are two through holes 8 on the mounting plate 31, and a touch bead 7 is respectively arranged at the middle position in each through hole, and on the wire card slot A screw hole is provided, and the locking lead screw is threadedly connected with the lead slot through the screw hole, and the two plugs of the insulating U-shaped mounting rod 5 are inserted in the through hole.

[0020] The insulating U-shaped installation rod 5 includes a U-shaped fork 51 and an insulating rod 53, the U-shaped fork and the insulating rod are connected by a butterfly buckle 52, the front end of ...

Embodiment 2

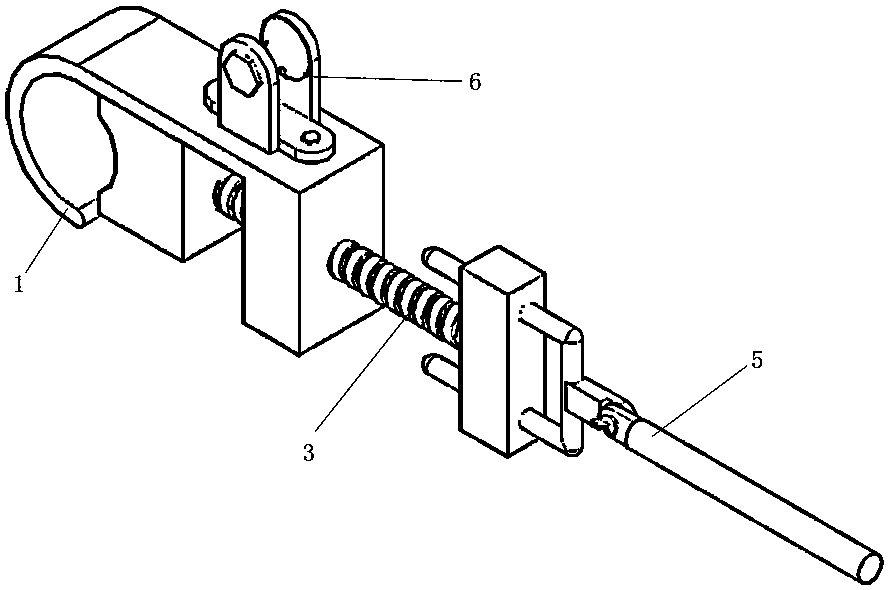

[0024] like figure 2 As shown, the flow pulley 6 is installed on the side wall of the wire clamping groove 1 described in this embodiment through the installation hole, and the rest is the same as that of the embodiment 1.

[0025] This embodiment is used on wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com