Inclined tube sedimentation tank water distribution rectification device and control method thereof

A technology of inclined tube sedimentation tank and rectification device, which is applied in the direction of separation method, precipitation separation, chemical instrument and method, etc., can solve the problems of unstable operation effect of inclined tube sedimentation tank, and achieve the effect of optimized combination mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below with reference to the drawings and embodiments.

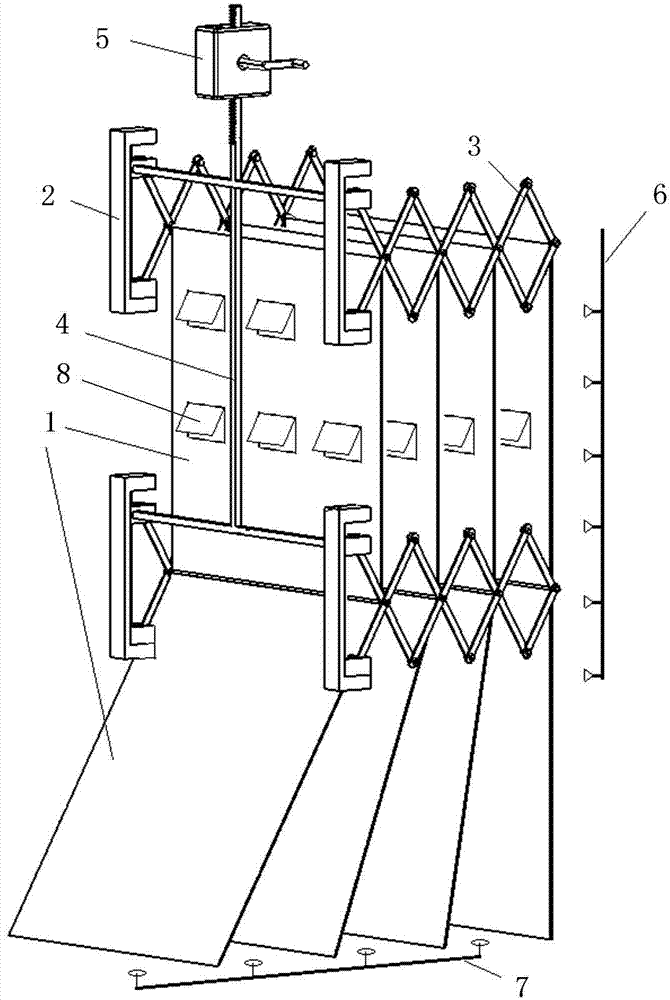

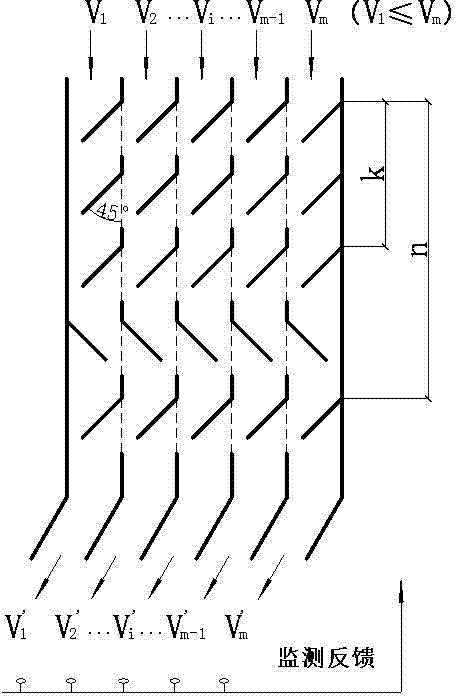

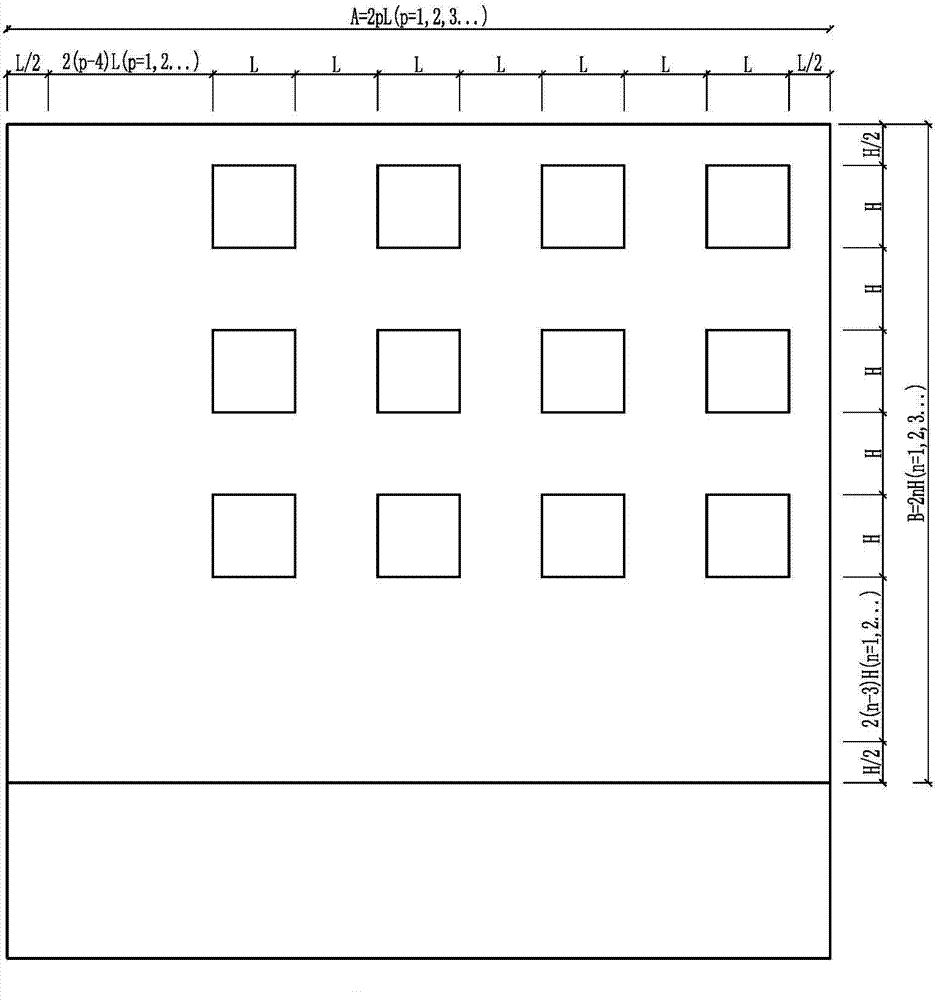

[0015] The present invention is a water distribution and rectification control method for inclined tube sedimentation tanks, which mainly includes a rectification device with flocculation and synergistic effects, such as figure 1 As shown, the rectifying device includes a deflector 1, the deflector is divided into upper and lower parts, the upper half is a vertical deflector, the lower half is an inclined deflector, and the inclined deflector is sandwiched between the inclined deflector and the horizontal plane. The angle is between 60 and 90°. The rectifying device is provided with a number of baffles 1, which are fixed in the inclined tube sedimentation tank by a telescopic device. The farther the distance from the inclined retaining wall at the end of the water distribution area is, the lower half of the baffle is connected to The greater the angle of the horizontal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com