A bimetallic temperature compensation plate forming method and mold

A technology of temperature compensation sheet and forming die, which is applied in the stamping field of bimetallic temperature compensation sheet forming for aviation, can solve the problems of linear dimension and shape tolerance tolerance, high labor intensity, high scrap rate, etc., and achieve flat punching section Straightforward, improved work efficiency, great economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

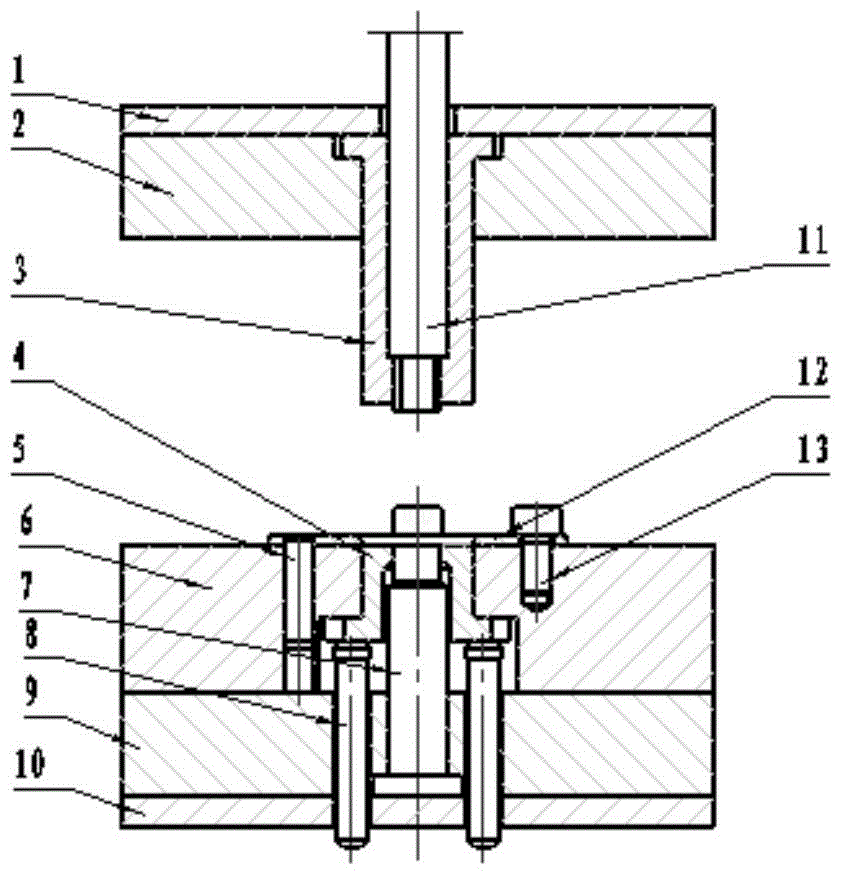

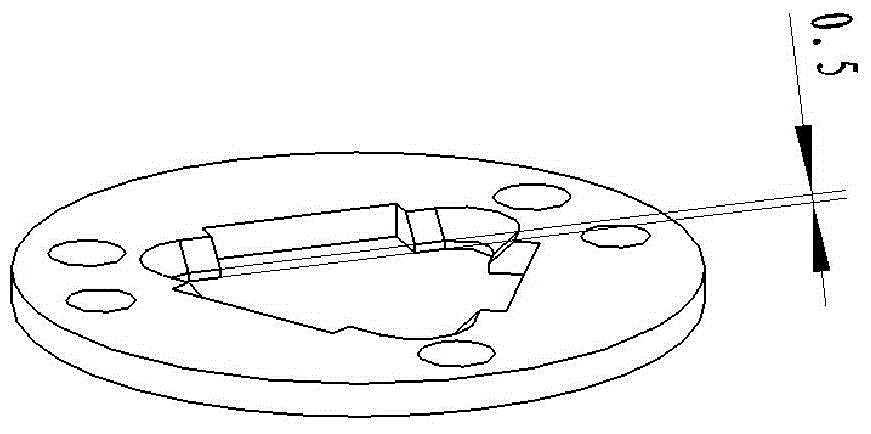

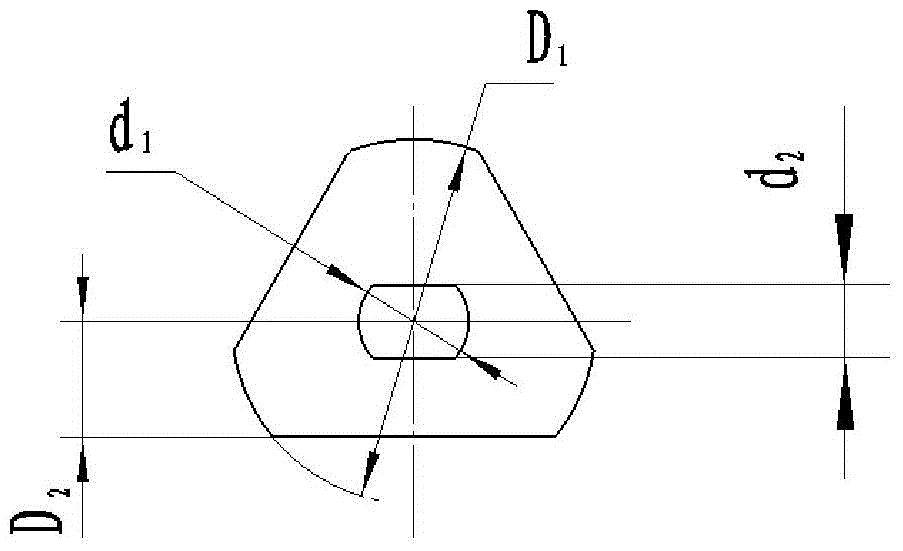

[0043] see figure 1 , which is a structural schematic diagram of the bimetallic temperature compensation plate forming die of the present invention. The mold consists of an upper mold and a lower mold. Wherein, the upper mold includes a convex and concave mold and an upper ejector arranged inside it. The lower mold includes a die, a punch, a lower ejector, and a positioning plate. The lower ejector is movably socketed on the punch, and the die is set outside the lower ejector. And the buffer in the press constitutes the lower ejection mechanism. The positioning plate connects the die through three evenly distributed screws and two symmetrical pins, and ensures the relative positional relationship between the positioning surface and the cutting edge of the die.

[0044] In addition, the convex and concave molds are fixed on the upper mold by the upper fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com