Machining method for worm gear pair

A processing method and technology of worm gear pair, applied in the direction of worm gear, worm, components with teeth, etc., can solve problems such as the difficulty of worm gear hob, and achieve the effect of eliminating poor matching effect, good meshing effect and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention comprises the following steps:

[0033] (I) Manufacture of worm gear

[0034] A. According to the parameters of the worm wheel in the worm gear pair to be processed, select the gear hob with the same modulus and tooth profile angle as the modulus m and tooth profile angle α of the worm wheel;

[0035] B. Adjust the angle of the gear hob according to the lift angle λ of the worm in the worm gear pair to be processed, so that the worm gear with the same helix angle as the worm lift angle λ can be processed.

[0036] (Ⅱ) Manufacture of worm

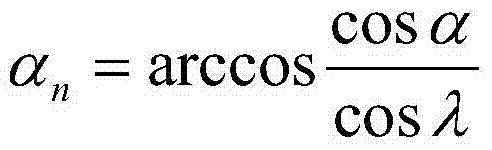

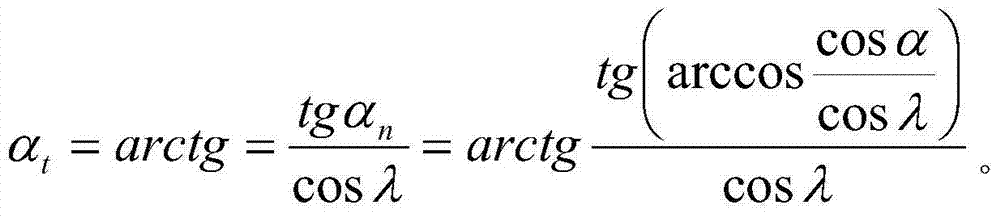

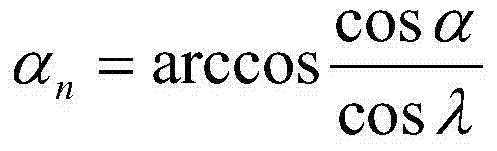

[0037] a. Calculate the turning tool tooth profile angle α for processing the worm according to the parameters of the worm in the worm gear pair to be processed t ;

[0038] b. According to the calculated turning tool tooth profile angle α t Create corresponding tool setting samples;

[0039] c. Sharpen the turning tool according to the tool setting template;

[0040] d. Install the tool and turn the workpi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com