Copper cylinder orienting mechanism

A technology of directional mechanism and copper pillars, which is applied in the direction of coating, etc., can solve the problems that the holes on the copper pillars and the mold core cannot be matched circularly and circularly, and the winding cannot be carried out effectively, so as to improve production efficiency, The effect of reducing speed and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

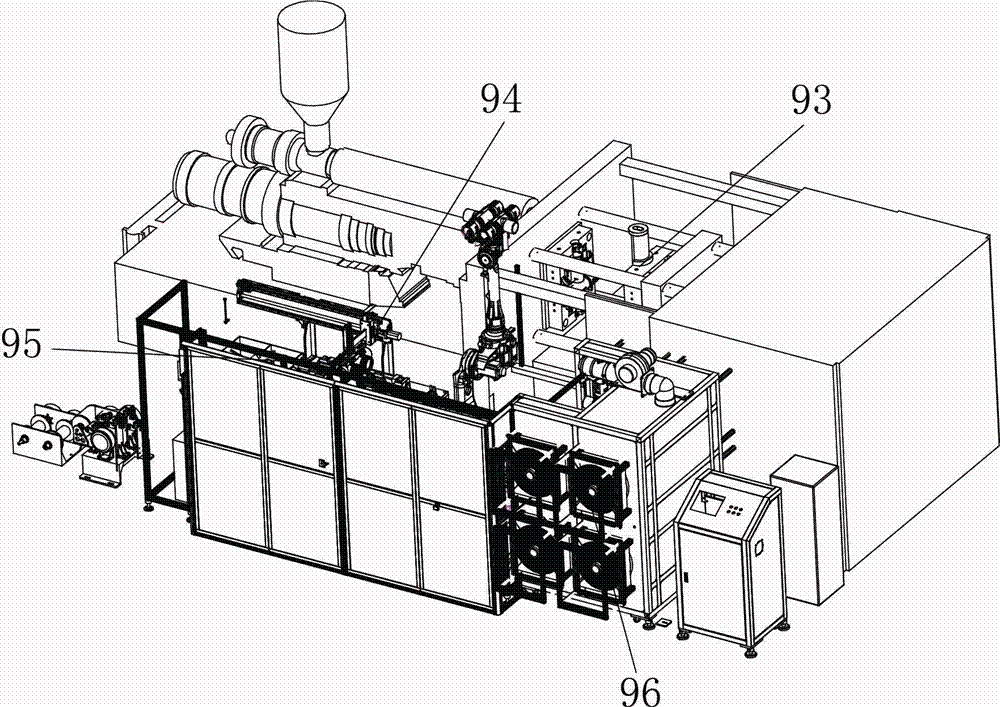

[0029] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment: see figure 1 , automatic production equipment for electrofusion pipes, including copper column feeding mechanism, copper column orientation mechanism, injection mold 93, loading and unloading mechanism 94, electrofusion pipe demoulding structure 95 and cooling system 96.

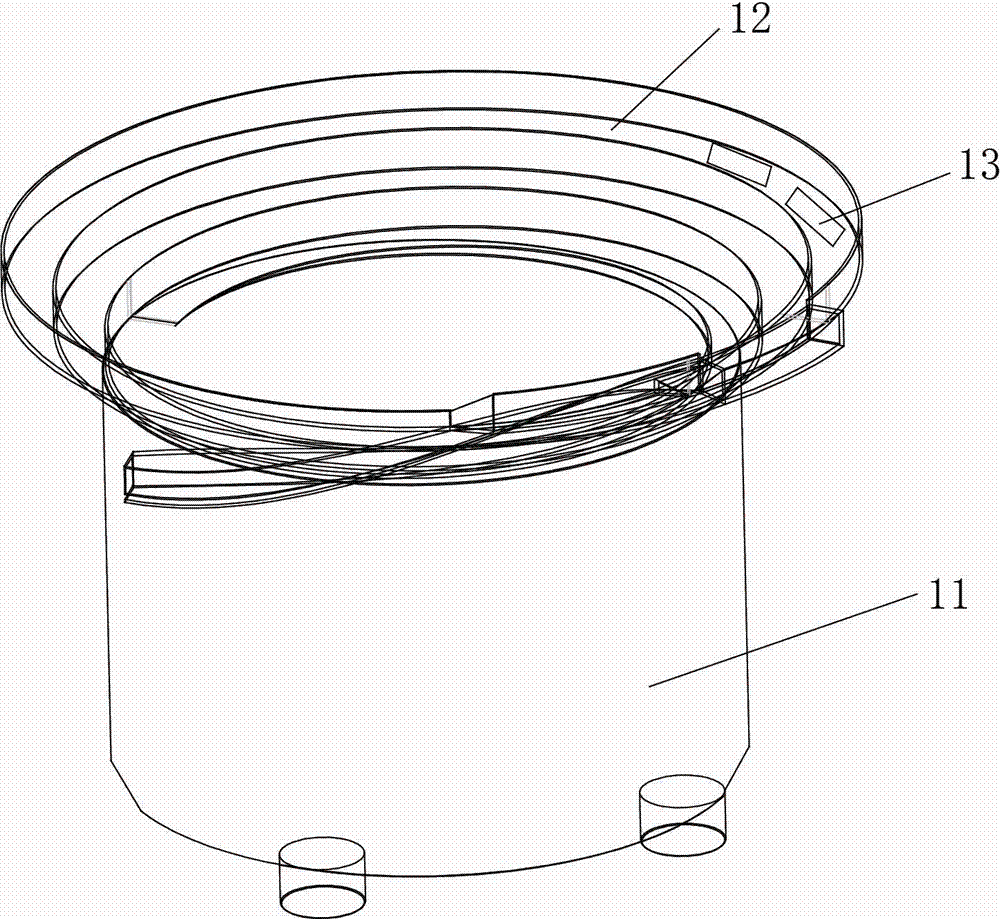

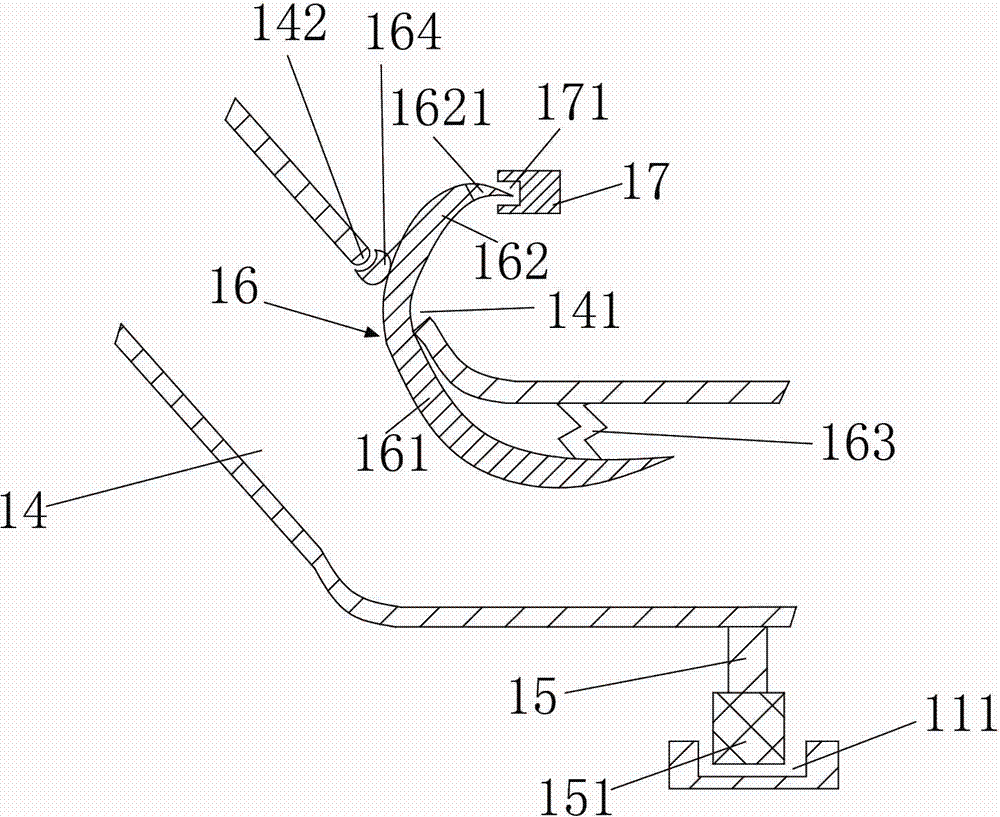

[0030] see Figure 2-4 , the feeding mechanism of the copper column, including a vibrating plate, the vibrating plate includes a vibrating plate body 11 and a track 12, the vibrating plate body 11 holds workpieces, and the track 12 is arranged on the vibrating plate body 11 and is arranged on the vibrating plate body 11 The workpiece is transported, and several gaps 13 are provided on the track 12, and the lower side of the gap 13 is rotatably connected with a blanking channel 14, and a pulley support frame 15 is arranged on the lower side wall of the blanking channel 13, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com