A window profile shaping platform

A technology of shaping tables and window profiles, which is applied in the field of shaping tables, can solve the problems of ignoring the effective treatment of waste water and waste gas, insufficient water and energy saving, and large vibration of the shaping table, so as to achieve fast drainage without being affected, convenient and orderly operation and management, and avoid Install Clutter Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

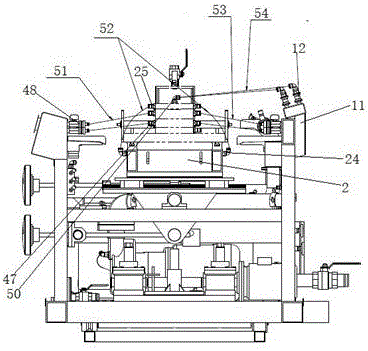

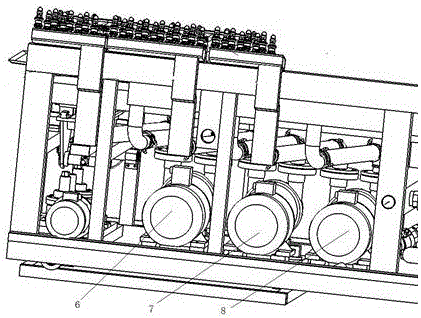

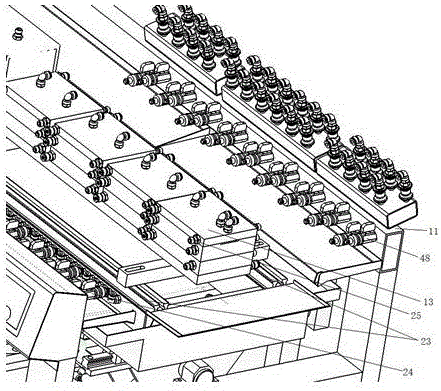

[0054] like Figure 1 to Figure 15 As shown, a window profile shaping table includes a frame 1, a support table 2, a shaping vacuum section 3, a shaping die section 4, an eddy current pump 5 for pumping eddy currents for the shaping die section 4, and three vacuuming for the shaping vacuum section 3 The vacuum pumps are frequency conversion vacuum pump 6, water ring vacuum pump 7 and water ring vacuum pump 8 respectively.

[0055] The support table 2 is arranged in the middle of the frame, and the shaping vacuum section 3 and the shaping die section 4 are installed on the support table 2. One side of the frame is provided with a vacuum device connected to the shaping vacuum section 3 through a pipeline. The vacuum pump and the eddy current pump are connected to a water collecting device that can recover water and can reduce noise. The water collecting device is connected to the frame through a heat exchange device, and water is introduced into the frame. The frame is used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com