A kind of nc automatic right-angle track

A right-angle and orbital technology, which is applied in the direction of conveyor objects, conveyors, mechanical conveyors, etc., can solve the problems of increased orbital space requirements, impossible to complete right-angled rotary motion, and inability to separate moving parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

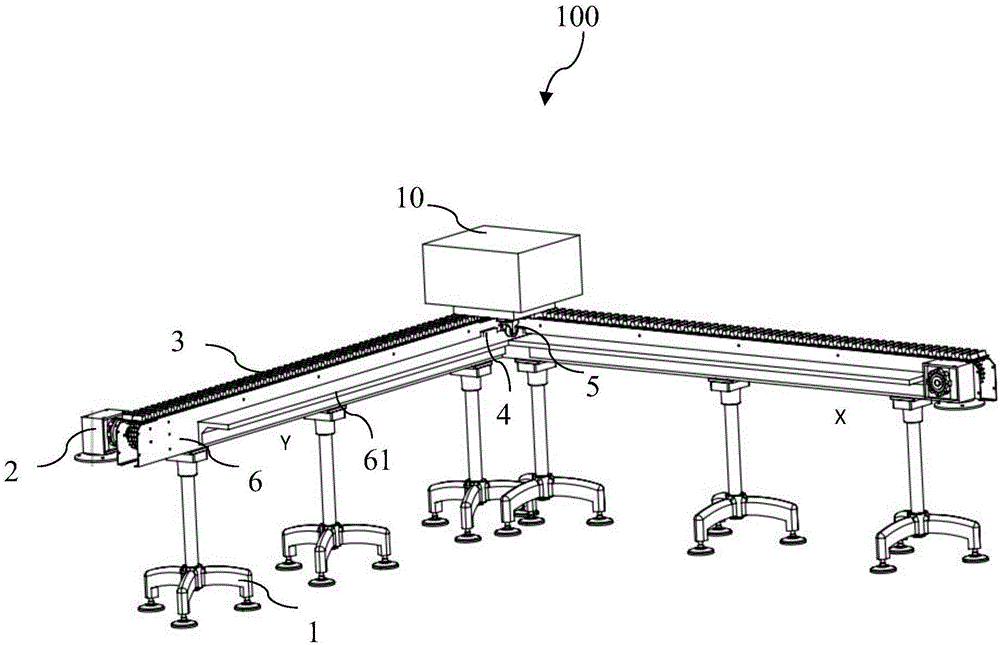

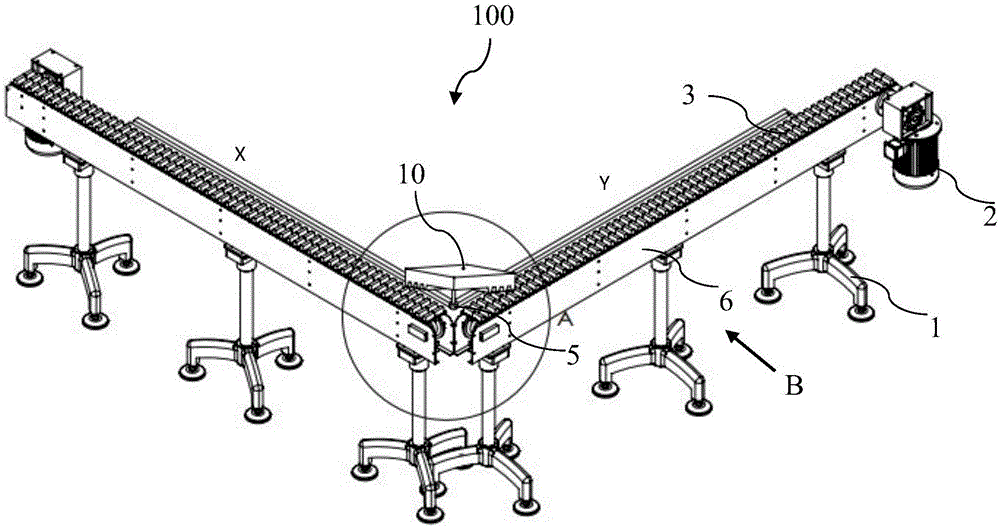

[0023] figure 1 It is a structural schematic diagram of the NC automation right-angle track in this embodiment.

[0024] figure 2 for figure 1 Rear view of the right-angle track for NC automation in .

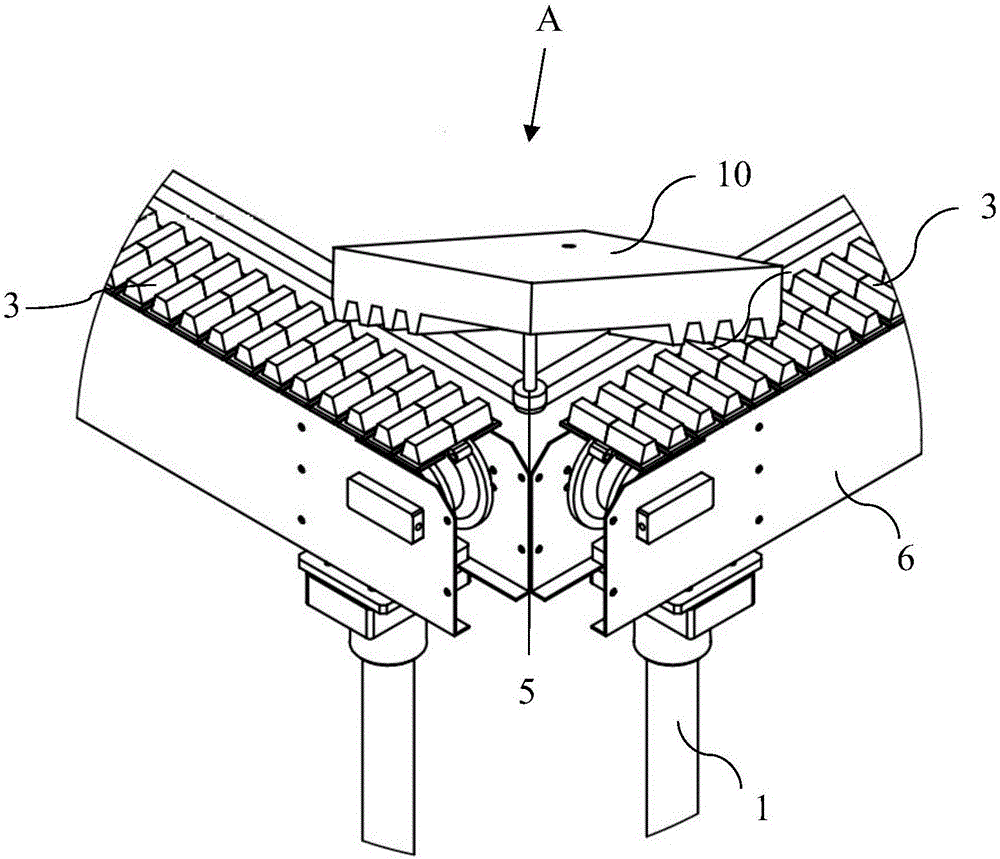

[0025] Such as figure 1 and figure 2 As shown, the NC automation right-angle track 100 is composed of two parts with the same structure and forming a right angle. Among the two parts, one is arranged along the X-axis, which is called the X-axis track, and correspondingly, the other part is called the Y-axis track. The specific structure of the NC automated right-angle track is described in detail below.

[0026] The NC automated right-angle track 100 includes a supporting part 1 , a driving part 2 , a transmission part 3 , an induction part 4 , a universal wheel device 5 and sheet metal shells 6 arranged on both sides of the transmission part 3 . The support part 1 includes an X-direction support part and a Y-direction support part forming a right angle; the drive part ...

Embodiment 2

[0040] In the second embodiment, the same structures as in the first embodiment are given the same symbols, and the same descriptions are omitted.

[0041] Figure 7 It is a structural schematic diagram of the NC automation right-angle track in this embodiment.

[0042] Such as Figure 7 As shown, the difference between the NC automated right-angle track 200 and the NC automated right-angle track 100 in Embodiment 1 lies in the transmission part 7. The transmission part 7 consists of a slide rail 71 close to the drive part 2 and a tooth shape close to the right-angle intersection. Band 72 composed.

[0043] The structure of the bottom end of the moving part 20 is also improved accordingly, that is, the outer ends on the left and right sides are chute 201 matched with the slide rail, and the structure of the inner bottom end of the chute is the same as that of the moving part 10 in the first embodiment.

[0044] When the moving part 20 starts to move from the end of one trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com