An automatic feeding system for automobile glass base

A technology for automatic feeding and automotive glass, which is applied in the stacking, unstacking, and packaging of objects, which can solve the problems of time-consuming, labor-intensive and labor-intensive, and achieve the goals of simple loading operation, improved yield rate, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

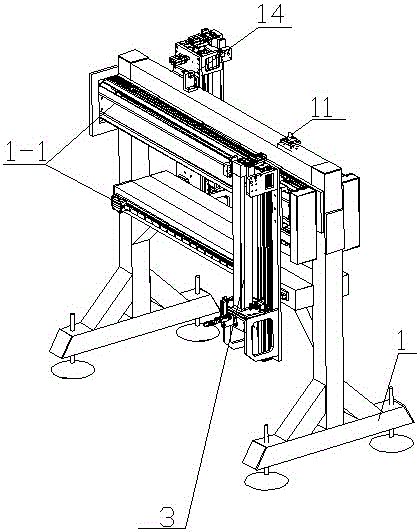

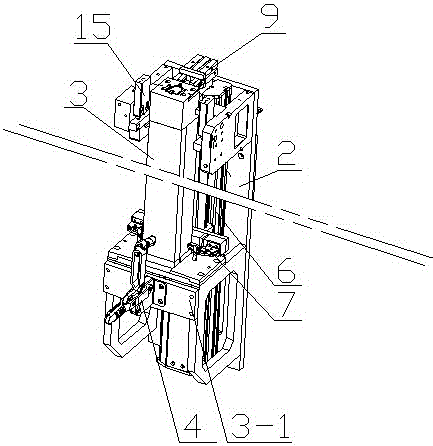

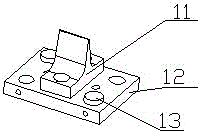

[0022] Such as figure 1 , 2 , 3, the present invention includes a frame 1, a pair of base stacking devices, a pair of top tightening devices, a pair of base lifting devices, a pair of deviation correction devices, a paper pressing device and a paper blowing device. There are two pairs of sliding tables 1-1, and the base stacking device includes a magazine mounting seat 2 and a magazine 3, and the magazine mounting seat 2 is installed on one of the two pairs of sliding tables 1-1, and one side of the magazine 3 is provided with The movable door, the top of the magazine 3 is provided with a base outlet, and the two ends of the magazine 3 are respectively installed on the magazine mounting seat 2 through the magazine bracket, and the top tightening device includes the clamp 4 and the clamp mounting seat, and the clamp 4 passes through the clamp The clamp mounting seat is installed on the magazine support 3-1 at the bottom of the magazine 3, and the clamp 4 tightens the dodge doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com