Slip-casting material of clay cement mortar

A technology of grouting materials and clay water, which is applied in the field of grouting materials, can solve the problems of different grouting effects and achieve the effect of simple process formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

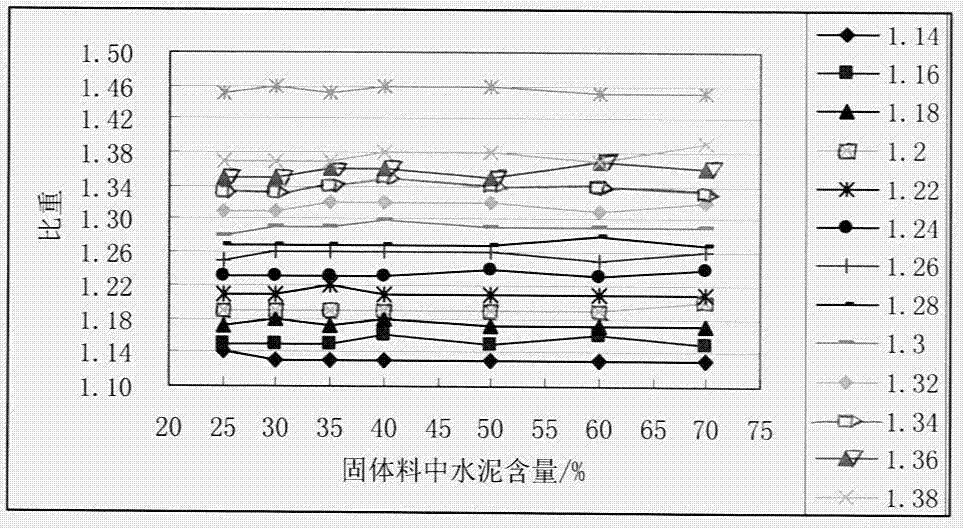

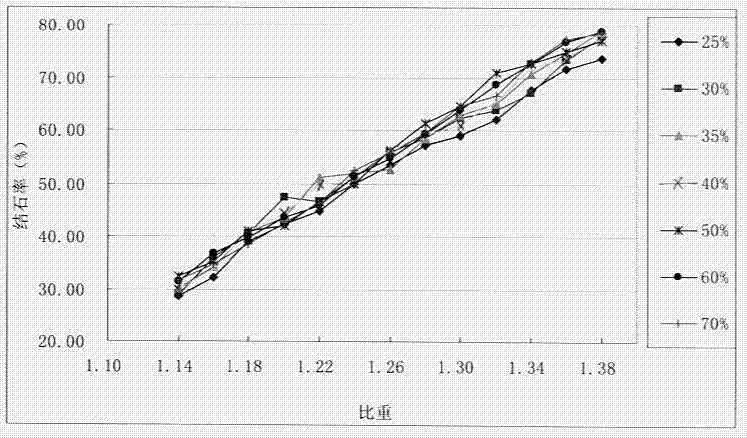

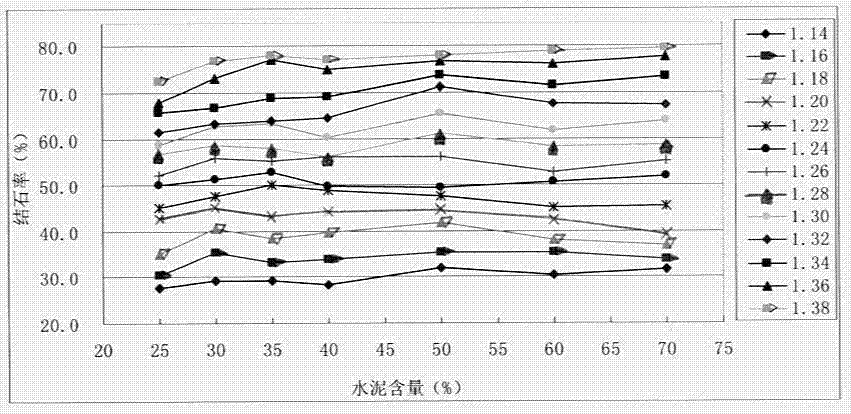

[0030] In this example, the total amount of solid material is 200 g. Under the condition that the proportion of solid material remains unchanged, clay-cement slurries with different specific gravity are prepared by changing the amount of water added. The ratio of solid material in this test is expressed by cement weight, and the weight ratio of cement is 25%. 1.34, 1.36, 1.38.

Embodiment 2

[0032] The weight ratio of the cement in this embodiment is 30%, and other implementation modes are the same as in Example 1.

Embodiment 3

[0034] The weight ratio of the cement of the present embodiment is 35%, and other embodiments are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| stone rate | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| stone rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com