Photocuring screen printing ink and preparation method thereof

A light-curing and mesh technology, applied in the printing field, can solve the problems of slow light-curing rate, high amount of ozone, and rising surface temperature, and achieve the effects of increased light-curing speed, easy-to-use process formula, and improved adhesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

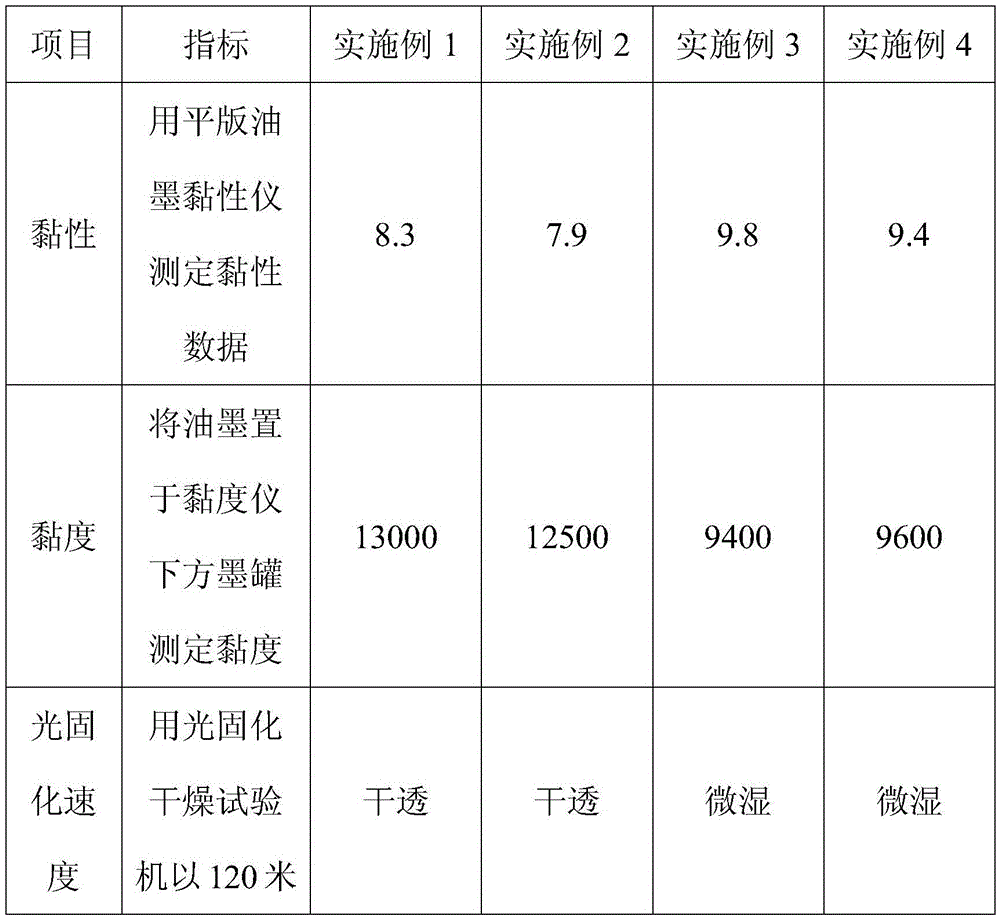

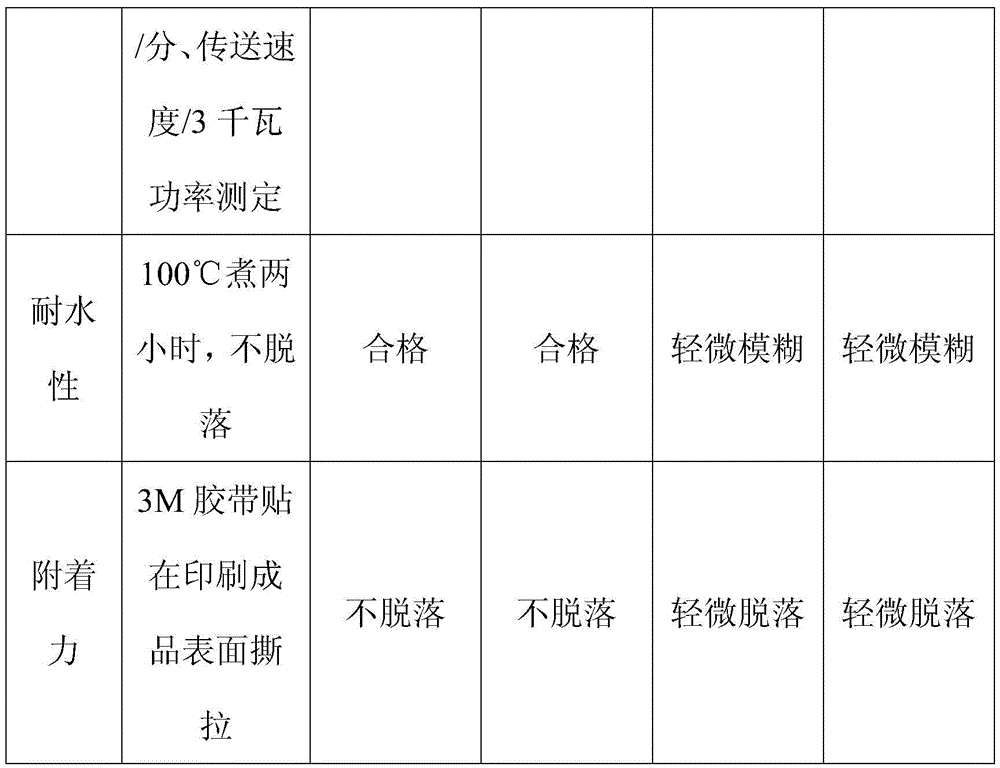

Examples

Embodiment 1

[0022] It consists of the following components in parts by weight: polyurethane 16%, water-based silicone waterproofing agent 9%, polytetrafluoroethylene 2%, isopropyl thioxanthene 4.5%, carbon black 6%, ethylene glycol diacrylate 3.5%, 0.35% of 3-aminopropyltriethoxysilane, Span-401.1%, 2.1% of zinc naphthenate, 1.1-2.2% of triethylamine, the mass ratio of 2-ethylhexyl acrylate to zinc sulfate is A 2:1 mixture of 17%, the balance being hydroxyethyl acrylate.

[0023] Its preparation process steps:

[0024] (1) 16% of the polyurethane, 9% of water-based silicone waterproofing agent, 2% of polytetrafluoroethylene, 4.5% of isopropylthioxanthene, 6% of carbon black, ethylene glycol, and Alcohol diacrylate 3.5%, 3-aminopropyltriethoxysilane 0.35%, Span-401.1%, zinc naphthenate 2.1%, triethylamine 1.1-2.2%, acrylate-2-ethylhexyl and sulfuric acid Add 17% of the mixture with a mass ratio of zinc of 2:1 and the rest of hydroxyethyl acrylate to the mixer for shaking and dispersing, ...

Embodiment 2

[0027] It consists of the following components in parts by weight: 11% polyurethane, 11% water-based silicone waterproofing agent, 3% polytetrafluoroethylene, 2-methyl-2-(4-morpholinyl)-1-[4- (Methylthio)phenyl]-1-acetone 3.7%, disazo dye 6.6%, trimethylolpropane triacrylate 4.5%, 3-aminopropyltriethoxysilane 0.45%, polysorbate- 801.3%, 1.9% dibutyl dilaurate, 1.2% triethylamine, 13% mixture of 2-ethylhexyl acrylate and zinc sulfate with a mass ratio of 2:1, and the balance is hydroxyethyl acrylate.

[0028] Its preparation process steps:

[0029] (1) The polyurethane 11%, water-based silicone waterproofing agent 11%, polytetrafluoroethylene 3%, 2-methyl-2-(4-morpholinyl)-1 calculated by weight parts of the formula -[4-(methylthio)phenyl]-1-acetone 3.7%, disazo dye 6.6%, trimethylolpropane triacrylate 4.5%, 3-aminopropyltriethoxysilane 0.45%, Polysorbate-801.3%, dibutyl dilaurate 1.9%, triethylamine 1.2%, 13% mixture of 2-ethylhexyl acrylate and zinc sulfate with a mass rati...

Embodiment 3

[0032] It consists of the following components in parts by weight: 16% polyurethane, 9% water-based silicone waterproofing agent, 2% polytetrafluoroethylene, 4.5% isopropylthioxanthene, 6% carbon black, ethylene glycol diacrylate 3.5%, 3-aminopropyltriethoxysilane 0.35%, Span-40 1.1%, zinc naphthenate 2.1%, ammonia water with a concentration of 20% 1.1-2.2% based on the mass of ammonia, acrylic acid-2-ethyl Hexyl ester 17%, balance is hydroxyethyl acrylate.

[0033] Its preparation process steps:

[0034](1) 16% of the polyurethane, 9% of water-based silicone waterproofing agent, 2% of polytetrafluoroethylene, 4.5% of isopropylthioxanthene, 6% of carbon black, ethylene glycol, and Alcohol diacrylate 3.5%, 3-aminopropyltriethoxysilane 0.35%, Span-40 1.1%, zinc naphthenate 2.1%, ammonia water with a concentration of 20% is 1.1-2.2% based on the mass of ammonia, acrylic acid- Add 17% of 2-ethylhexyl ester, and the balance is hydroxyethyl acrylate, and add it into the mixer to s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com