Knitted fabric pretreatment cold-pad-batch assistant and preparation method thereof

A technology of knitted fabrics and cold stacking, which is applied in fiber processing, plant fibers, textiles and papermaking, etc. It can solve the problems of low selectivity of processed products, unstable products, and large safety hazards, so as to improve production conditions and overcome indentation , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

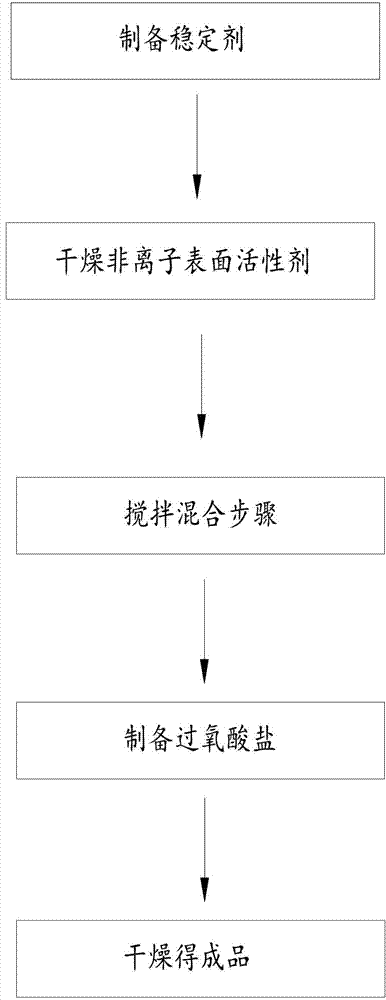

[0089] The preparation method of knitted fabric pretreatment cold pile auxiliary agent comprises the following steps:

[0090] (1) Preparation of stabilizer

[0091] Prepare the following components by weight:

[0092] Sodium silicate 0.5-1.5 parts,

[0093] Anhydrous sodium metasilicate 7.5-22.5 parts,

[0094] Sodium acetate 2-6 parts,

[0095] The above components are stirred and mixed to obtain a stabilizer;

[0096] (2) Dry nonionic surfactant

[0097] Prepare nonionic surfactant by weight, and spray dry it;

[0098] (3) Stirring and mixing step

[0099] Adding water treatment agent, release agent, stabilizer and activator in parts by weight to the dried nonionic surfactant, and mechanically stirring and mixing;

[0100] (4) Preparation of peroxysalt

[0101] Prepare the following components by weight:

[0102] Sodium perborate 15-21 parts,

[0103] Sodium percarbonate 30-42 parts,

[0104] 5-7 parts of ammonium persulfate,

[0105] The above components are st...

Embodiment 1

[0109] Knitted fabric pretreatment cold stacking aid, comprising the following components by weight:

[0110] 50 parts of peroxy salt,

[0111] 10 parts of stabilizer,

[0112] 1 package caustic soda,

[0113] Sodium hexametaphosphate 1 part,

[0114] 1 part of EDTA,

[0115] EN-70 1 part.

[0116] Wherein, the peroxo-salt consists of the following components by weight:

[0117] Sodium perborate 15 parts,

[0118] 30 parts of sodium percarbonate,

[0119] Ammonium persulfate 5 parts.

[0120] Described stabilizer is made up of the component of following parts by weight:

[0121] 0.5 parts of sodium silicate,

[0122] 7.5 parts of anhydrous sodium metasilicate,

[0123] Sodium acetate 2 parts.

[0124] The preparation method of knitted fabric pretreatment cold pile auxiliary agent comprises the following steps:

[0125] (1) Preparation of stabilizer

[0126] Prepare the following components by weight:

[0127] 0.5 parts of sodium silicate,

[0128] 7.5 parts of a...

Embodiment 2

[0145] Knitted fabric pretreatment cold stacking aid, comprising the following components by weight:

[0146] 60 parts of peroxy salt,

[0147] Stabilizer 20 parts,

[0148] 2 parts of packaged caustic soda,

[0149] 3 parts trisodium phosphate,

[0150] 5 parts of EDTA,

[0151] EN-70 10 parts.

[0152] Wherein, the peroxo-salt consists of the following components by weight:

[0153] Sodium perborate 18 parts,

[0154] 36 parts of sodium percarbonate,

[0155] Ammonium persulfate 6 parts.

[0156] Described stabilizer is made up of the component of following parts by weight:

[0157] 1 part sodium silicate,

[0158] 15 parts of anhydrous sodium metasilicate,

[0159] Sodium acetate 4 parts.

[0160] The preparation method of knitted fabric pretreatment cold stacking aid comprises the following steps:

[0161] (1) Preparation of stabilizer

[0162] Prepare the following components by weight:

[0163] 1 part sodium silicate,

[0164] 15 parts of anhydrous sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com