Small vehicle shock absorber

A small car and shock absorber technology, applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc., can solve the problems of low radial load strength, affecting the service life of bearings, and large friction coefficients, etc., to achieve Strong anti-aging ability, extended service life, high lubricating and non-stick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

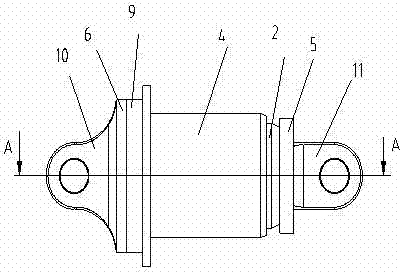

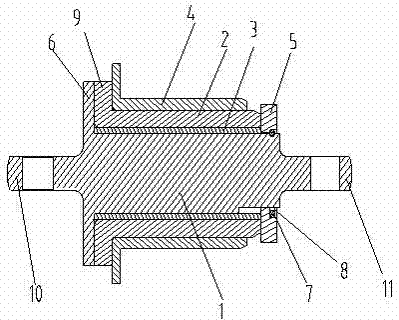

[0016] figure 1 It is a schematic diagram of the structure of the present invention, figure 2 for figure 1 A-A direction view, as shown in the figure: the small automobile shock absorber of this embodiment includes a positioning mandrel 1 and a shock absorbing sleeve assembly that is sleeved on the positioning mandrel 1, and the shock absorbing sleeve assembly at least includes an outer sleeve The tube 4 and the rubber sleeve 2 vulcanized and molded in the outer sleeve 4; the rubber has a wide range of adaptable stiffness, is not sensitive to stress concentration or surface defects, and has small damping and less energy absorption, thereby ensuring that the shock absorbing sleeve assembly It has a large torsion angle, a strong ability to bear radial loads, improves the radial shock absorption effect, and improves better cushioning performance for small cars. At the same time, the rubber also has excellent fatigue resistance, which can strengthen the shock absorber sleeve Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com