A cassette and substrate transfer device

A transfer device and substrate technology, applied in the directions of transportation and packaging, conveyor objects, optics, etc., can solve the problems that the cassette cannot be rotated automatically, the cassette cannot be moved to accurately measure the moving distance, and the space of the sub-cassette cannot be fully utilized. Achieve automatic and precise control of moving distance, increase the number of applications, and precisely control the size of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

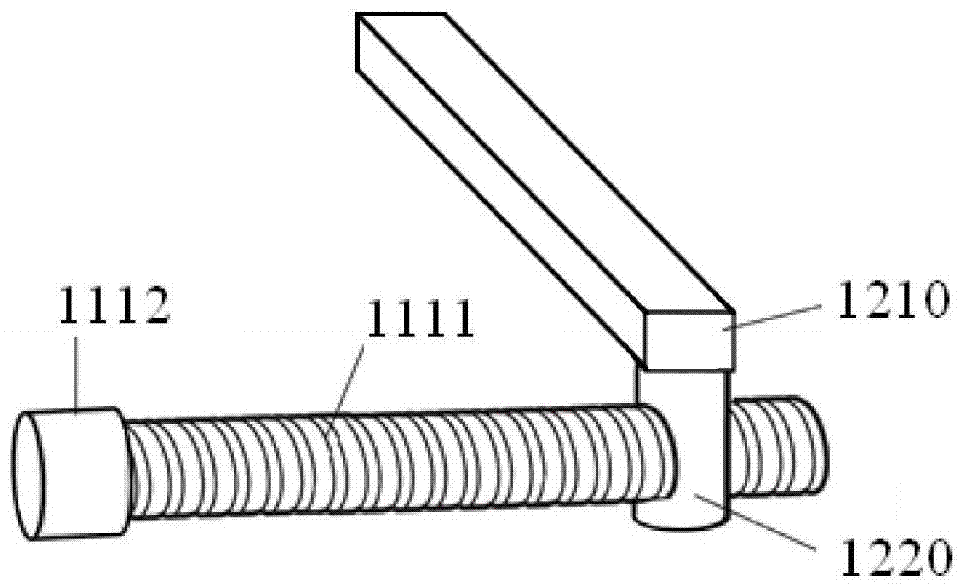

[0082] According to one embodiment of the present invention, the second sliding member 2212 and the second guide rail 2310 are made of sucker type de-energized electromagnets.

[0083] According to the embodiment of the present invention, the space between the second slider 2212 and the second guide rail 2310 is made of a suction cup type de-energized electromagnet, the magnetism disappears when the power is turned on, and the two are in a free state and can slide, and they are attracted when the power is turned off Fastened together so they can be controlled by switching power on and off.

[0084] According to an embodiment of the present invention, a second laser distance measuring device 2400 is disposed on both the second frame body 2100 and the rotating unit 2200 for measuring the distance between them.

[0085] According to the embodiment of the present invention, the second laser distance measuring device 2400 arranged on the second frame body 2100 is preferably arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com