Goods intensive storage method, device and system and storage medium

A technology for goods and shelves, applied in the field of intensive storage methods, systems, storage media, and devices for goods, can solve problems such as the inability to meet the needs of intelligent intensification, and achieve the effect of making full use of warehouse space and reducing labor costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

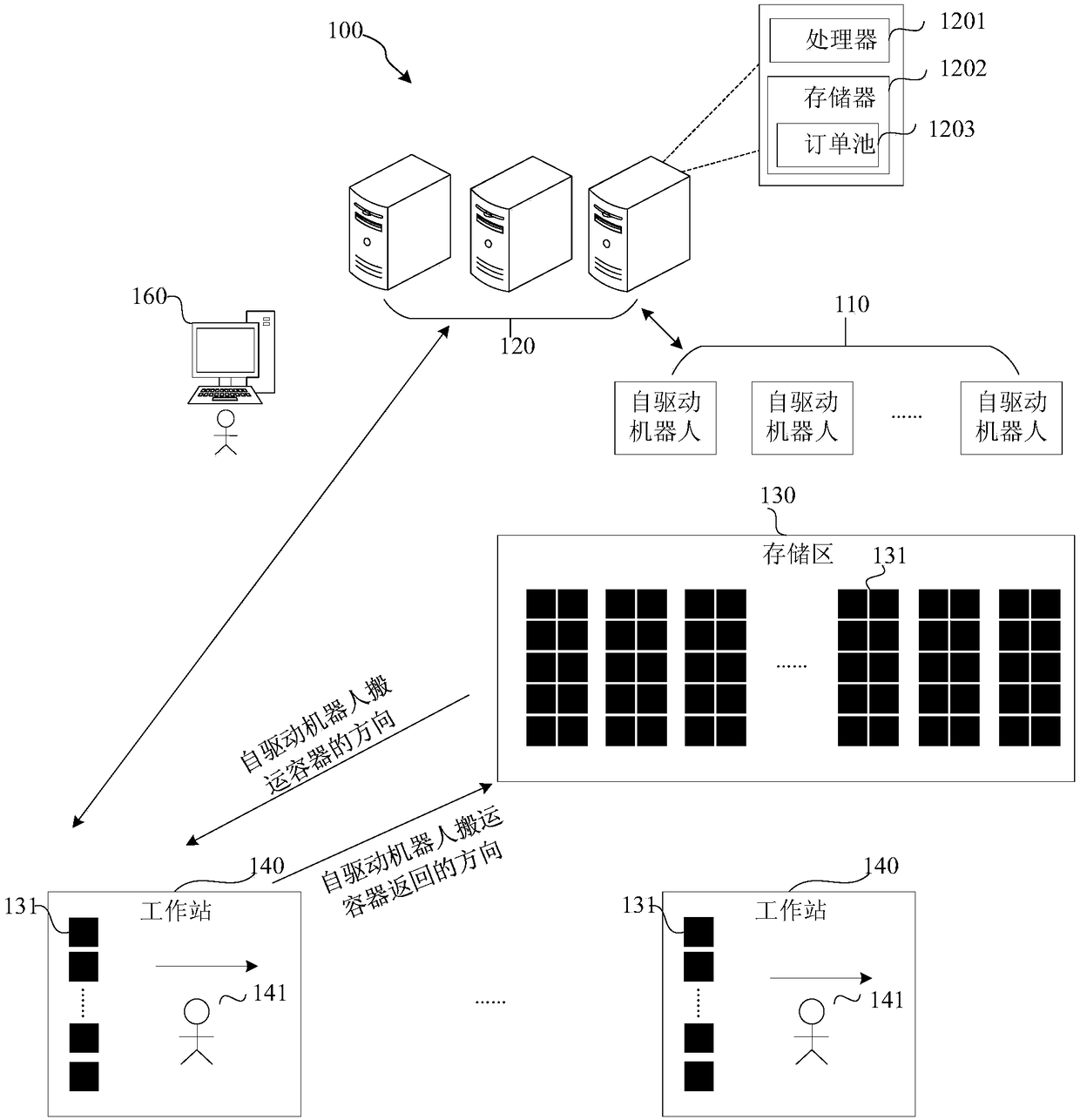

[0070] Figure 4 It is a schematic flow chart of the cargo-intensive storage method provided in Embodiment 1 of the present invention. This embodiment is applicable to the situation of cargo storage. The method can be executed by the cargo-intensive storage device provided in the embodiment of the present invention. The device can be controlled by software and / or or hardware, and can be integrated into a cargo-intensive storage system.

[0071] like Figure 4 As shown, the cargo-intensive storage methods include:

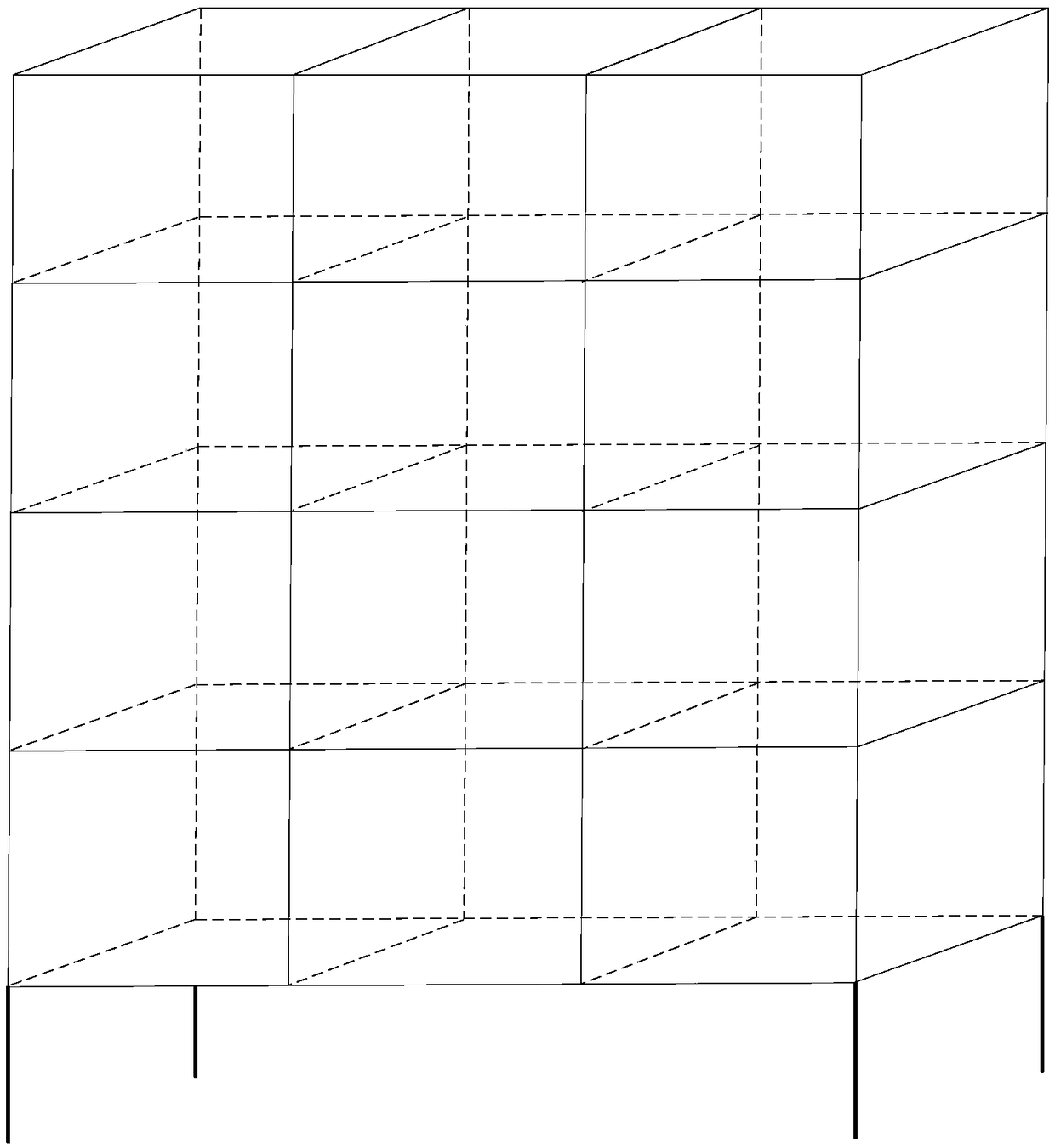

[0072] S410. Determine the target shelf pointed to by the handling task from the shelf array; the number of shelves in any horizontal row and any vertical row of the shelf array is at least 3.

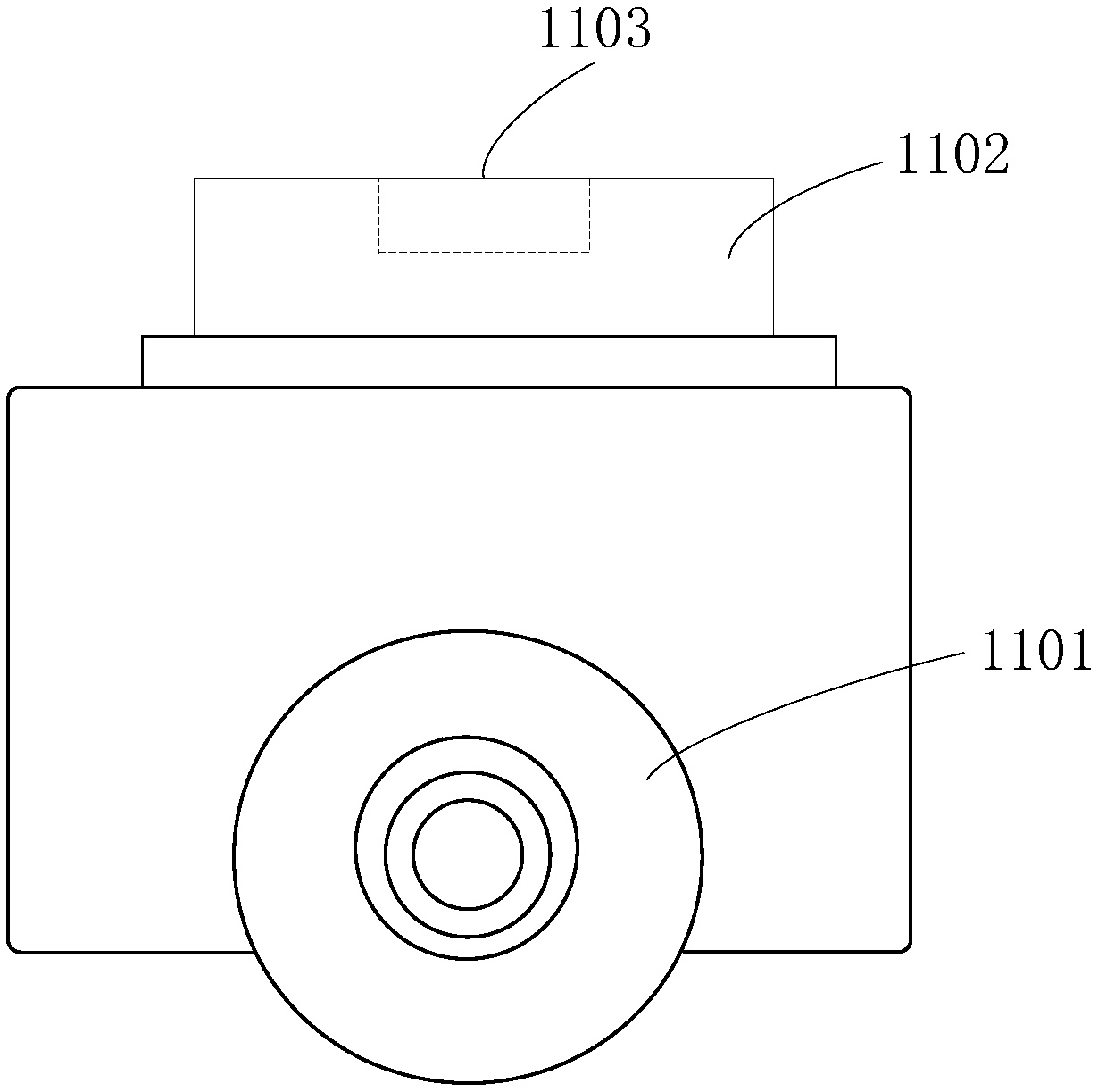

[0073] Wherein, the handling task can be determined by the operation console. For example, at the workstation, there are some A items that need to be stored on the shelves in the storage area, and the handling task can be generated through the operation console. Then in t...

Embodiment 2

[0082] Image 6 It is a schematic flow chart of the method for densely storing goods provided in Embodiment 2 of the present invention. On the basis of the above-mentioned embodiments, this embodiment is optimized as follows: the determination of the position type of the target shelf in the shelf array, and determining the handling strategy according to the position type, including: if the target shelf is determined If the position of the shelf is the first position type, then according to the first position type, determine that the handling strategy is direct handling; and controlling the self-driven robot to carry the target shelf based on the handling strategy includes: controlling the self-driven robot to move The target shelf is transported to the designated position of the transport task.

[0083] like Image 6 As shown, the goods-intensive storage method proposed in this application includes:

[0084] S610. Determine the target shelf pointed to by the handling task f...

Embodiment 3

[0094] Figure 7 It is a schematic flow chart of the method for densely storing goods provided in Embodiment 3 of the present invention. On the basis of the above-mentioned embodiments, this embodiment is optimized as: judging the position type of the target shelf in the dense shelf arrangement, and determining the handling strategy according to the position type, including: if judging the position of the target shelf is the second position type, then according to the second position type, determine that the transport strategy is indirect transport; and controlling the self-driven robot to transport the target shelf based on the transport strategy includes: according to the position of the target shelf, Determine the route shelf; control the self-driven robot to move the route shelf away, and then transport the target shelf to the designated position of the handling task.

[0095] like Figure 7 As shown, the cargo-intensive storage methods include:

[0096] S710. Determine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com