Thin film transistor and manufacturing method thereof as well as display device

A technology of thin film transistors and manufacturing methods, which is applied in the direction of transistors, semiconductor/solid-state device manufacturing, semiconductor devices, etc., can solve the problems of increased number of masks, complex processes, and increased costs, so as to reduce the number of patterning processes and reduce manufacturing costs , The effect of saving etching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

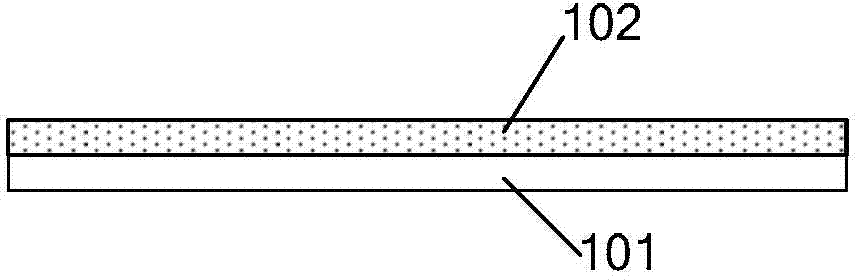

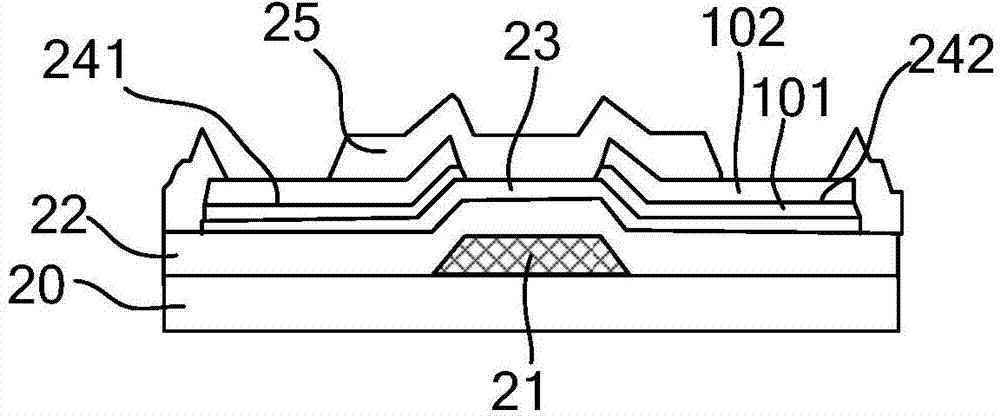

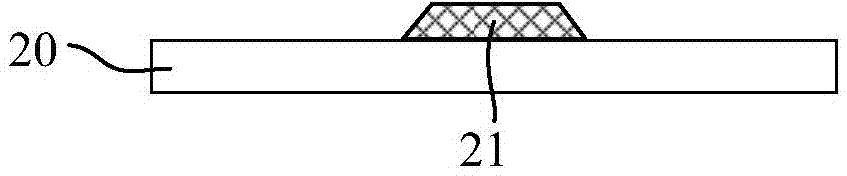

[0040] An embodiment of the present invention provides a thin film transistor, the thin film transistor includes: a gate, an active layer, a source and a drain, the source and the drain are formed of at least two materials, the source and the drain The forming material can undergo cell reaction in the corresponding etching solution to be etched, and the etching solution does not corrode the active layer.

[0041] Aiming at the problem that the active layer of the existing TFT is easily corroded by the etchant used in the source and drain formation process, this embodiment adopts a new solution idea: the material of the source and drain in the thin film transistor is selected to be A material that undergoes a battery reaction in an electrolyte, and at the same time, the electrolyte corresponding to the battery reaction is used as an etching solution in the formation process of the source and drain electrodes, and the electrolyte is used as an etching solution for the thin film t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com