Electro-adhesion gripper for holding workpieces

A technology for grabbers and workpieces, which is applied in the direction of electrostatic attraction holding devices, circuits, electrical components, etc., can solve the problems of expensive electroadhesive grabbers and complex structures of electroadhesive grabbers, and achieve Uniform force distribution, avoiding voltage breakdown, and increasing the effect of total inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

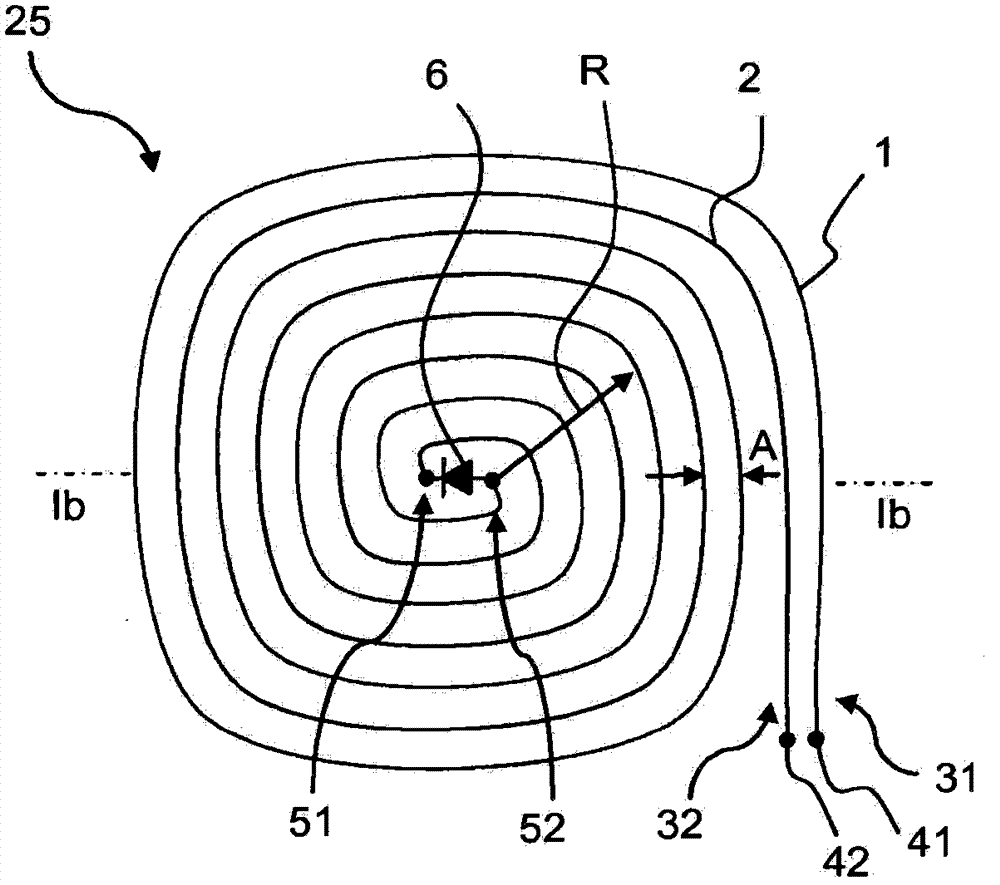

[0063] Figure 1a The region of the electrode arrangement 25 of the first embodiment of the electroadhesive gripper according to the invention is shown in a schematic plan view.

[0064] The electrode arrangement 25 comprises a first helical electrode 1 (shown in dashed lines) and a second helical electrode 2 (shown in solid). The two electrodes 1 , 2 extend completely bifilarally and each comprise approximately four turns; the distance A of the electrodes 1 , 2 (measured approximately perpendicular to the local electrode extension) is essentially the same for all helix radii R here. On the outer ends 31 , 32 of the electrodes 1 , 2 respectively, voltage terminals 41 , 42 for connecting a voltage, preferably an alternating voltage, are provided. Diode components 6 , here comprising individual diodes, are connected to the inner ends 51 , 52 of the electrodes 1 , 2 ;

[0065] To operate the electroadhesion, a voltage is connected with a polarity in the blocking direction of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com