Air ring air speed distribution measurement and adjustment device and method of coal mill

An adjustment device and coal mill technology, which is applied in the direction of measuring fluid velocity by using pressure difference, grain processing, etc., to achieve the effect of uniform wind speed distribution, flexible adjustment of wind speed distribution, and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

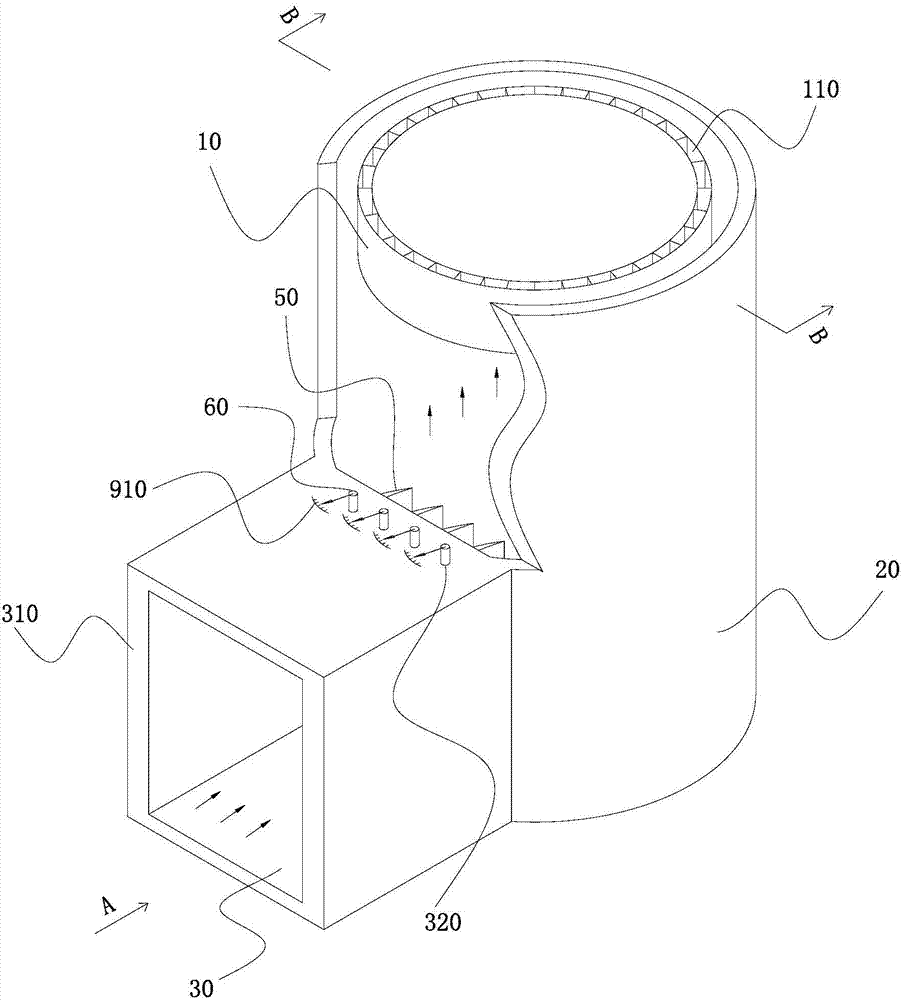

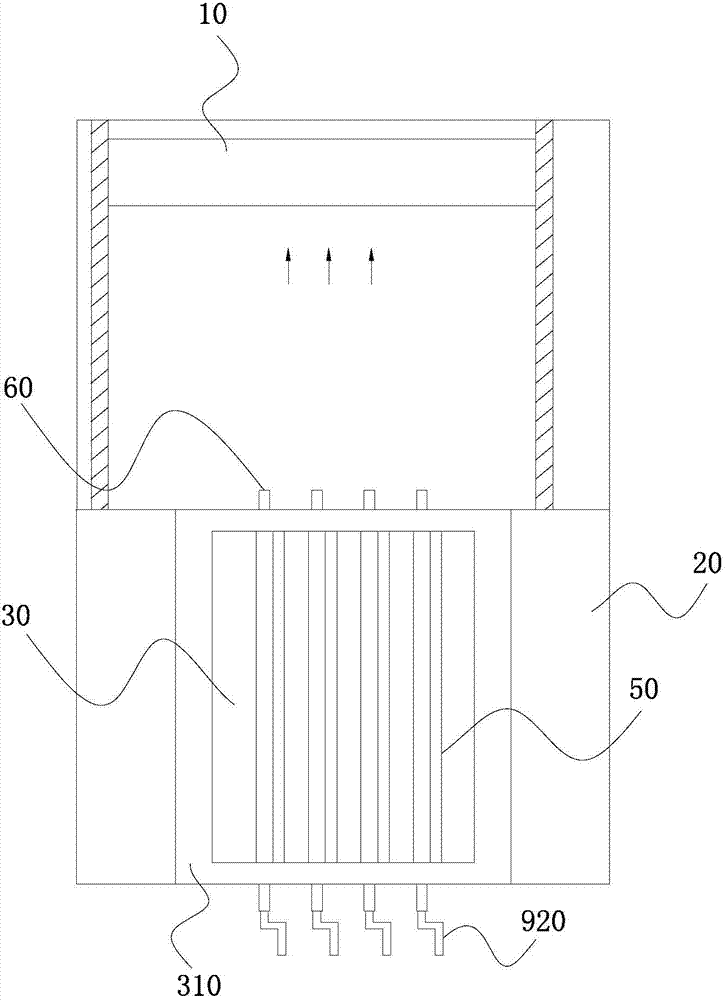

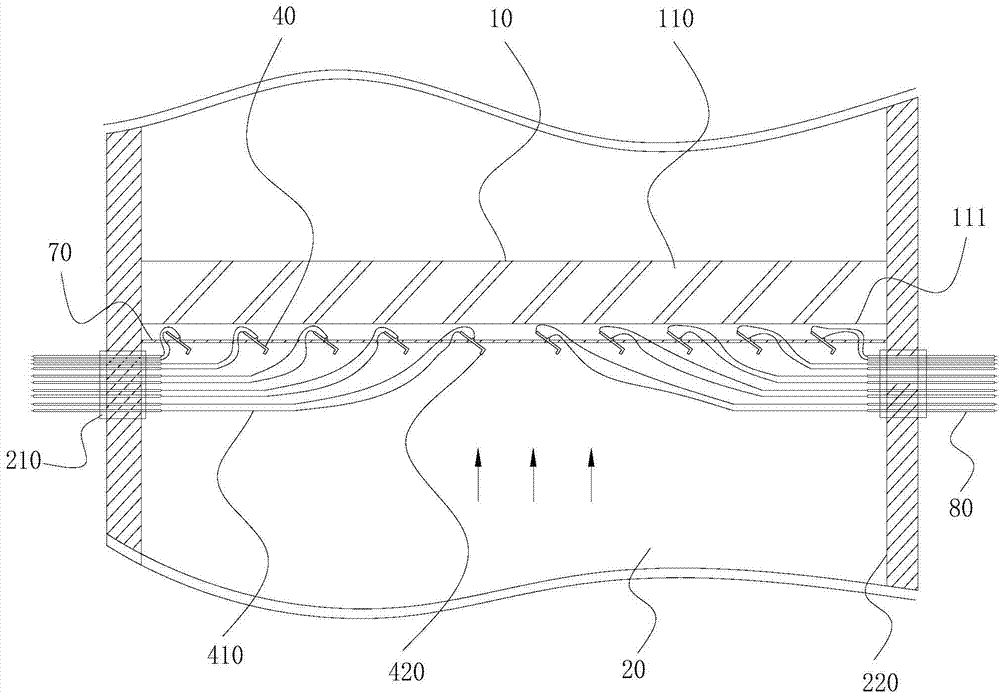

[0031] Such as Figure 1 to Figure 4 As shown, an air ring wind speed distribution measuring and adjusting device of a coal mill, the air ring 10 is provided with a plurality of air ring ports 110, and the air ring ports 110 are provided with an air inlet port 111, and the coal mill includes a wind ring 10 Below, and close to the gravel coal header 20 of the air inlet end 111, and the inlet air channel 30 communicating with the side wall of the gravel coal header 20, the wind ring wind speed distribution measurement and adjustment device of the coal mill includes a wind ring mouth 110- A corresponding plurality of Pitot tubes 40, and a plurality of pressure measuring devices (not marked in the drawings) corresponding to the Pitot tubes 40, a plurality of connecting pipes 410, a plurality of deflectors 50 located in the inlet air duct 30, And the adjustment ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com